Building envlope

- 1. ENERGY CONSCIOUS ARCHITECTURE PRESENTATION ON BUILDING ENVELOPE SUBMITTED BY: ANANT KIRAN RIYA SONALI SUCHAR CHARU

- 2. Introduction • The building envelope is physical separator between the exterior and the interior of the building and fenestration systems. • Opaque components include walls, roofs, slabs on grade (in touch with ground), basement walls, and opaque doors. • Fenestration systems include windows, skylights, ventilators, and doors that are more than one- half glazed. The envelope protects the building’s interior and occupants from the weather conditions and shields them from other external factors e.g. noise, air pollution, etc. • Envelope design strongly affects the visual and thermal comfort of the occupants, as well as energy consumption in the building.

- 3. Heat transfer takes place through walls, windows, and roofs in buildings from higher temperature to lower temperature in the following three ways: • Conduction:- It is the transfer of heat by direct contact of particles of matter within a material or materials in physical contact. • Convection:- It is the transfer of heat by the movement of a fluid (air or gas or liquid). • Radiation:- It is the movement of energy/heat through space without relying on conduction through the air or by the movement of air. Heat transfer in buildings

- 4. • A building element is usually composed of a number of different materials. When materials are placed in series, their thermal resistances are added so that the same area will conduct less energy for a given temperature difference. Formation of air film at the surface of wall or roof, due to convection movements of air, also provides resistance to the heat flow, similar to the construction material. The total resistance of the wall or roof includes all of the resistances of the individual materials that make it up as well as both the internal and external air-film resistance. Thermal Resistance of an Element Consisting of Homogenous Layers Mandatory Requirements Fenestration • Heat transfer across glazing products or fenestration (windows, door, and skylights) is similar to the heat transfer that takes place across walls and roofs through conduction and convection. • So, U-factor of glazing is analogous to the U-factor of wall assembly. • In addition, direct solar radiation contributes to the solar heat gain through the fenestration system. • Fenestration and doors must be rated using procedures and methods specified in the ECBC

- 5. Three fenestration performance characteristics are significant in the ECBC: 1. Heat transfer coefficient (U-factor), 2. Solar Heat Gain Coefficient (SHGC) 3. Air Leakage • The U-factor of fenestration is very important to the energy efficiency of buildings, especially in cold climates . • The U-factor must account for the entire fenestration product, including the effects of the frame, the spacers in double glazed assemblies, and the glazing. • There are a wide variety of materials, systems, and techniques used to manufacture fenestration products, and Fenestration U-factors must be determined in accordance with ISO-15099.

- 6. • The U-factor (thermal conductance), must account for the entire fenestration system including the effects of the frame, the spacers in double glazed assemblies, and the glazing. • There are a wide variety of materials, systems, and techniques used to manufacture fenestration products, and accurately accounting for these factors is of most importance when meeting the fenestration requirements. • ECBC has used W/m2·C OR W/m2·K as the unit for U-factor. Heat transfer coefficient (U-factor)

- 7. • SHGC is the ratio of the solar heat gain that passes through the fenestration to the total incident solar radiation that falls on the fenestration. • The solar heat gain includes directly transmitted solar heat and absorbed solar radiation, which is then re-radiated, converted, or conducted into the interior space. • SHGC indicates how well the glazing/glass and fenestration products insulate heat caused by sun falling directly on the glass. • In hot climates, SHGC is more important than the U-factor of the glazing. • A lower SHGC means that lesser heat can pass through the glazing. • The SHGC is based on the properties of the glazing material, whether the window has single, double, or triple glazing, and the window operation (either operable or fixed). • Glazing units with a low SHGC will help reduce the air conditioning energy use during the cooling season. Solar Heat Gain Coefficient (SHGC)

- 8. • Air leakage can also occur through opaque construction. • Apart from adding cooling or heating load in the building, air leakage can cause condensation within walls and roof can damage insulation material and degrade other building materials. • Air leakage for glazed swinging entrance doors and revolving doors shall not exceed 5.0 l/s·m2. • Air leakage for other fenestration and doors shall not exceed 2.0 l/s·m2. • The first set of air leakage requirements deals with inadvertent leaks. • Air leakage is the passage of air through a building envelope, wall, window, joint, etc. • Leakage to the interior is referred to as infiltration and leakage to the exterior is referred to as ex-filtration. • Excessive air movement significantly reduces the thermal integrity and performance of the envelope and is, therefore, a major contributor to energy consumption in a building. Building Envelope Sealing Air Leakage

- 9. • A tightly constructed building envelope is largely achieved through careful construction practices and attention to detail. Building envelopes should be carefully designed to limit the uncontrolled entry of outdoor air into the building. • Air leakage introduces sensible heat into conditioned spaces. In climates with moist outdoor conditions, it is also a major source of latent heat. Latent heat must be removed by the air-conditioning system at considerable expense. In addition to causing energy loss, excessive air leakage can cause condensation to form within and on walls. This can create many problems including reducing insulation R-value, permanently damaging insulation, and seriously degrading materials. Building Envelope Sealing • It can rot wood, corrode metals, stain brick or concrete surfaces, and in extreme cases cause concrete to break, bricks to separate, mortar to crumble and sections of a wall to fall jeopardizing the safety of occupants. It can corrode structural steel, re-bar, and metal hangars and bolts with very serious safety and maintenance consequences. Moisture accumulation in building materials can lead to the formation of mold that may require extensive remedying the situation. Virtually anywhere in the building envelope where there is a joint, junction or opening, there is potential for air leakage. Air leakage will cause the HVAC system to run more often and longer at one time, and still leave the building uncomfortable for its occupants. • All openings in the building envelope, including joints and other openings that are potential sources of air leakage, should be to be sealed to minimize air leakage. It means that all gaps between wall panels, around doors, and other construction joints must be well sealed. Ceiling joints, lighting fixtures, plumbing openings, doors, and windows should all be considered as potential sources of unnecessary energy loss due to air infiltration.

- 10. ECBC identifies several areas in the building envelope where attention should be paid to infiltration control. These include: • Joints around fenestration and doorframes. • Openings at penetrations of utility services through roofs, walls, and floors. • Site-built fenestration and doors. • Building assemblies used as ducts or plenums. • Joints, seams, and penetrations of vapor retarders. • All other openings in the building envelope. It is also recommended that junctions between walls and foundations, between walls at building corners, between walls and structural floors or roofs, and between walls and roof or wall panels. • Fenestration products, including doors, can also significantly contribute to infiltration. • Although not included in the Code, it is recommended that fenestration products should have infiltration less than 0.4 cfm/ft² (2.0 l/s·m²). • For glazed entrance doors that open with a swinging mechanism and for revolving doors, it is recommended that infiltration be limited to 1.0 cfm/ft² (5.0 l/s·m²).

- 11. For envelope component-based compliance approach, ECBC sets requirements for: • Exterior roofs and ceilings • Cool roofs • Opaque walls • Vertical fenestration • Skylights • The National Building Code of India, 2005 has divided the country in five climate zones: (Hot-Dry; Warm-Humid; Composite; Temperate/Moderate; and Cold), • the air temperature and humidity variations that exist need to be considered while designing the building envelope. Prescriptive Requirements

- 12. • The ECBC building envelope requirements are based on the climate zone in which the building is located. • Based on the characteristics of climate, the thermal comfort requirements in buildings and their physical manifestation in architectural form are also different for each climate zone (See Table 4.3). • These physical manifestations, in turn, dictates the ECBC requirements for the envelope, as well as other building components that are applicable to the building. Role of Climate Zone

- 15. Some recommended practices for proper installation and protection of insulation are provided below: Insulation • The first set of mandatory requirements addresses the proper installation and protection of insulation materials. • It is recommended that insulation materials be installed according to the manufacturer’s recommendations and in a manner that will achieve the rated insulation R-value. Compressing the insulation reduces the effective R-value and the thermal performance of the construction assembly.

- 16. Substantial Contact • It is recommended that insulation be installed in a permanent manner and in substantial contact with the inside surface of the construction assembly. If the insulation does not entirely fill the cavity, the air gap should be on the outside surface. • Maintaining substantial contact is particularly important (and problematic) for batt insulation installed between floor joists. Without proper support, gravity will cause the insulation to fall away from the floor surface, leaving an air gap above the insulation. • Air currents will ultimately find their way to the gap, and when they do, the effectiveness of the insulation will be substantially reduced. Insulation Above Suspended Ceilings • It is not good practice to install insulation directly over suspended ceilings with removable ceiling panels. • This is because the insulation’s continuity is likely to be disturbed by maintenance workers. Also, suspended ceilings may not meet the ECBC’s infiltration requirements unless they are properly sealed. • Compliance with this requirement could have a significant impact in some parts of the country, as it is common practice to install • insulation over suspended ceilings • . Many building codes will consider the space above the ceiling to be an attic and require that it be ventilated to the exterior. • If vented to the exterior, air in the attic could be quite cold (or hot) and the impact of the leaky suspended ceiling would be made worse.

- 17. Insulation Protection • It is strongly recommended that insulation be protected from sunlight, moisture, landscaping equipment, wind, and other physical damage. • Rigid insulation used at the slab perimeter of the building should be covered to prevent damage from gardening or landscaping equipment. Rigid insulation used on the exterior of walls and roofs should be protected by a permanent waterproof membrane or exterior finish. • In general, a prudent designer should pay attention to moisture migration in all building construction. • Vapor prevent moisture from condensing within walls, roofs, or floors but care should be taken to install them on the correct side (warmer or cooler side) of the walls and roofs to prevent water damage. • Water condensation can damage the building structure and can seriously degrade the performance of building insulation and create many other problems such as mold and mildew. • The designer should evaluate the thermal and moisture conditions that might contribute to condensation and make sure that vapor retarders are correctly installed to prevent condensation. • In addition to correctly installing a vapor retarder, it is important to provide adequate ventilation of spaces where moisture can build up.

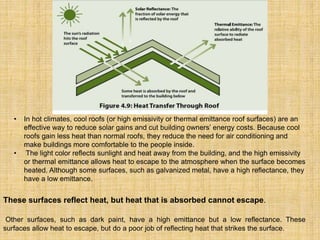

- 20. Cool Roofs Depending on the material and construction, a roof will have different properties that determine how it conducts heat to the inside of the building. “Cool roofs” are roofs covered with a reflective coating that has a high emissivity property that is very effective in reflecting the sun’s energy away from the roof surface. These “cool roofs” are known to stay 10°C to 16°C cooler than a normal roof under a hot summer sun; this quality greatly reduces heat gain inside the building and the cooling load that needs to be met by the HVAC system. Reflectance & Absorptance • The heat transfer process involved in the roof, is similar to the heat transfer that takes in a wall. Heat transfer across the roof is more prominent compared to the wall because of higher incidence of solar radiation. • Depending on the properties of the roof material and construction, the roof reflects part of the solar radiation back to the environment, and absorbs the other part of the heat in the roof • Finally, portion of the absorbed heat in the roof is emitted as long-wave radiation back to the environment and the remaining part of the absorbed heat is conducted inside of the building. • This heat transfer process is governed by the Solar Reflectance and Emissivity (Thermal Emittance) properties of the roof material, apart from the thermal conductivity of the materials used in the roof.

- 21. • In hot climates, cool roofs (or high emissivity or thermal emittance roof surfaces) are an effective way to reduce solar gains and cut building owners’ energy costs. Because cool roofs gain less heat than normal roofs, they reduce the need for air conditioning and make buildings more comfortable to the people inside. • The light color reflects sunlight and heat away from the building, and the high emissivity or thermal emittance allows heat to escape to the atmosphere when the surface becomes heated. Although some surfaces, such as galvanized metal, have a high reflectance, they have a low emittance. These surfaces reflect heat, but heat that is absorbed cannot escape. Other surfaces, such as dark paint, have a high emittance but a low reflectance. These surfaces allow heat to escape, but do a poor job of reflecting heat that strikes the surface.

- 22. • Most cool roof materials for low-sloped roofs are white or another light color. For steep- sloped roofs that are often visible from the ground, roofing material manufacturers have developed popular roof colors other than white that will still reflect solar radiation or emit the sun’s energy away from the building. • Cool roofs have other benefits in addition to reducing operating absorbed heat costs. For building owners, they can cut maintenance costs and increase the life expectancy of the roof. • For society in general, cool roofs can even help to reduce the urban heat island effect and slow down global warming that makes our cities hotter and produces unhealthy air. Urban Heat Island effect • An Urban Heat Island is a metropolitan urban area, which is significantly warmer than its surroundings. • As population centers grow in size, they tend to have a corresponding increase in average temperature. • Scientists refer to this phenomenon as the “Urban Heat Island Effect”. The two main causes of the urban heat island is modification of the land surface by urban development and waste heat generated by energy usage. • One consequence of urban heat islands is the increased energy required for air conditioning and refrigeration in cities that are in comparatively hot climates.

- 23. Types of roofing products are available • Products for low-slope roofs, found on commercial and industrial buildings fall into two categories: single-ply materials and coatings. • Single-ply materials are large sheets of pre-made roofing that are mechanically fastened over the existing roof and sealed at the seams. • Coatings are applied using rollers, sprays, or brushes, over an existing clean, leak- free roof surface. • Products for sloped roofs are currently available in clay, or concrete tiles. • These products stay cooler by the use of special pigments that reflect the sun’s infrared heat. • In India, lime coats, white tiles grouted with white cement, special paints, etc. are used as cool roofing materials. Opaque Walls Wall opaque means a solid wall or fence constructed of brick, concrete, masonry, metal, stone, wood or other similar material that provides 100 percent screening.

- 24. • The prescriptive option limits vertical fenestration area to 40 percent of the gross above- grade wall area. With exceptions for some buildings, the area of west-oriented and east- oriented vertical fenestration must each not exceed the area of south-oriented vertical fenestration. • The prescriptive option limits skylight area to 5 percent of the gross roof area. In some larger spaces with high ceilings, the code requires a minimum skylight area for daY lighting. Vertical Fenestration The design and placement of windows and other openings in a building. ASHRAE Standard 90.1-2010 is the latest version of ASHRAE 90.1. Like all versions of the standard, its prescriptive building envelope option sets U-factor and SHGC requirements and fenestration area limits. Other compliance options allow greater design flexibility but are more complex. Regardless of the chosen compliance option, fenestration must not exceed mandatory air leakage limits.

- 25. Energy-Efficient Fenestration Products/ Assemblies. • Windows are affected by many factors, which in turn affect the comfort and energy performance of buildings. • A fenestration product is comprised of three areas: the vision area, the glazing, and the opaque area or the frame. • In a window, glazing is generally 90-95% of the total area and therefore the most important part to address for achieving energy efficiency. • However, the frame becomes important to optimize the overall energy efficiency of the window. The energy efficiency of a fenestration product is affected by: • Films which are applied to improve energy efficiency • Low emissivity (low-e) coatings for energy-efficient windows • Gas fill used in insulating glass units for energy-efficient windows • Insulating glass units for energy-efficient windows • Frame designs for energy-efficient windows • Reducing the air leakage of windows to improve energy efficiency • Number of layers of glass in the fenestration product.

- 26. • A skylight is a fenestration surface having a slope of less than 60 degrees from the horizontal plane. • Other fenestration, even if mounted on the roof of a building, is considered vertical fenestration. • Skylights can be installed into a roof system either flush-mounted or curb-mounted • In order to create a positive water flow around them, skylights are often mounted on “curbs” set above the roof plane. However, these curbs, rising 6 to 12 inches (15 to 30 centimeters) above the roof, create additional heat loss surfaces right where the warmest air of the building tends to collect. • Portions of roof that serve as curbs that mount the skylight above the level of the roof are part of the opaque building envelope. Skylights