Serena barbanotti INFN milano

- 2. Index Introduction: why accelerators as source for neutrons? General principles of neutron production with accelerators What is a high power accelerator and how does it work? General layout Superconductive choice Applications of accelerator driven neutron sources Waste Transmutation (ADS) Materials studies (SNS) Fusion (IFMIF)

- 3. Why Accelerators Easily pulsed beams No chain reactions Very high typical fluxes A 1 mA beam delivers to the target 6·10 15 particles per second

- 4. Accelerators and Neutrons The accelerator A particle accelerator is delivering energy to the beam via a rotational electric field acting on the charged particles. Depending on the reaction chosen for neutron production, either proton or deutons are accelerated (high intensity simple particles with maximum charge to mass ratio). Superconducting accelerators are preferred for their higher efficiency in the power conversion from plug to beam.

- 5. Accelerators and Neutrons The neutron source High intensity charged particle beams are used to produce high intensity neutron fluxes for several applications The neutron flux is determined by the charged particle flux through a simple nuclear process on a beam target (spallation or stripping reaction) Different materials are chosen and different particles are accelerated, depending on power density, application, …

- 6. Accelerators and Neutrons Beam target choice High Z materials for spallation -> high efficiency neutron conversion Liquid or solid, depending on power density for good neutron economy is required to minimize target dimension very high power density on target liquid target are preferred (heat removal by convection) solid target have power limit Beam – liquid target interface: window or windowless ? Window related problems: window cooling cyclic thermal loading on the window under creep condition very corrosive environment (using lead) radiation damage induced by proton and neutron in the window material

- 7. Neutron generation 1/3 Spallation reaction An heavy metal target hit by a high energy proton generates neutrons proton ~1 GeV -> 20 - 30 neutrons Characteristics : High conversion factor neutrons/protons Wide neutron energy spectrum For high neutron production efficiency, required high energy proton beam

- 8. Neutron generation 2/3 Stripping reaction An incident deuton hits a Lithium target nucleus; the target emits a neutrons and the deuton proceeds with most of its original momentum in almost its original direction Typical reactions: 7 Li(d,2n) 7 Be 6 Li(d,n) 7 Be 6 Li(n,T) 4 He Characteristics : Lower conversion factor Peaked neutron energy spectrum: 14 MeV Required low energy beam

- 9. Spallation reaction ADS SNS Neutron generation 3/3 Stripping reaction IFMIF Proton beam Proton beam

- 10. Applications 1/3 Nuclear fusion (IFMIF) Fusion reactors will produce high neutron fluxes at 14 MeV This will bring to high material irradiation To guarantee reactor operation, required materials with: ITER: 3 dpa/lifetime DEMO: > 20 dpa/year Required a material test facility for material verifications

- 11. Applications 2/3 Nuclear Waste Trasmutation (ADS) Problem: Disposal of Nuclear Waste Reduce radiotoxicity of the waste Minimize volume/heat load of waste Strategy: Partitioning and Transmutation Separate chemically the waste (Pu, MA, LLFF) Use the waste as fuel in dedicated transmuter systems Solution: a transmuter has 2 ingredients A subcritical reactor (k<1), with U-free fuel: chain reaction is not self-sustained An intense spallation source (high p flux on liquid lead target) : provides “missing” neutrons to keep the reaction going, with a broad energy spectrum (good for MA burning)

- 12. Application 3/3 Material science (SNS) Neutrons provide unique insight into materials at the atomic level: ‘ see’ light atoms in biomaterials and polymers study magnetic properties and atomic motion measure stress in engineering components

- 13. The accelerators ~ dm 2 ~ dm 2 ~ dm 2 Beam dimension 14 MeV Wide spectrum Wide spectrum Neutron energy 10 MW 1.4 MW ~ 20 MW Total beam power 2 * 125 mA 1.4 mA 20-40 mA Average beam current Continuous Pulsed: 60 Hz – 695 ns Continuous Beam operation Stripping deuton - Litium Spallation on liquid mercury Spallation on liquid lead/bismuth Neutron production deutons H-, converted in p at accumulator ring protons Accelerates With window With window Windowless Target area ~ 40 MeV ~ 1 GeV ~ 600-1000 MeV Beam energy IFMIF SNS ADS

- 14. Index Introduction: why accelerators as source for neutrons? General principles of neutron production with accelerators What is a high power accelerator and how does it work? General layout Superconductive choice Applications of accelerator driven neutron sources Waste Transmutation (ADS) Materials studies (SNS) Fusion (IFMIF)

- 15. Particle Accelerators The name Particle Accelerator is a historical one connected to the concept of an energy increase related to a velocity change, that is an acceleration. For protons and ions that has been the case for a while: Electrostatic accelerators Linacs Cyclotrons Synchrotron concept and strong focusing scheme pushed energies to e level where the Energy increase is dominated by the particle mass increase and the velocity is very close to the speed of light.

- 16. Basic Concepts: Fields Equation of motion and Lorentz force Electric field can transfer energy to the particles Magnetic field can guide the beam in a stable path All Particle Accelerators are based on these rules The beam moves inside a vacuum chamber Electromagnetic objects placed on the beam path perform the tasks: Magnets guide the beam on the chosen trajectory (dipoles) and provide focusing (quadrupoles) Resonant RF cavities (exceptions: Betatron, RFQ and Electrostatic Accelerators) are used to apply the electric accelerating field

- 17. Some Milestones for Accelerators 20th century first 25 years from 1928 to 1932 1928 1929 1944 1946 1950 1951 1956 1970 early 80's the last years Prehistory : fundamental discoveries made with "beams" from radioactive source trigger the demand for higher energies Cockcroft&Walton develop a 700kV electrostatic accelerator based on a voltage multiplier First Linac by Wideroe based on resonant acceleration Lawrence invents the cyclotron MacMillan, Oliphant & Veksler develop the synchrotron Alvarez builts a proton linac with Alvarez structures (2 mode) Christofilos patents the concept of strong focusing Alvarez conceives the tandem Kerst stresses in a paper the concept of a collider Kapchinski & Telyakov invent the radio-frequency quadrupole RFQ superconducting magnets for cylotrons and synchrotrons considerably boost the performance (energy for size) the development of superconducting accelerating cavities provides very high power conversion efficiency

- 18. Accelerators evolution: the Livingston chart Around 1950, Livingston made a quite remarkable observation : Plotting the energy of an accelerator as a function of its year of construction , on a semi-log scale, the energy gain has a linear dependence . 50 years later, that still holds true. In other words, so far, builders of accelerators have managed exponential growth , every ten years , roughly a factor of 33 is won . Note that for a given " family " of accelerators, saturation of maximum energy sets in after some time. future E = m c 2

- 19. An RF source generates an electric field in a region of a resonant metallic structure; the particles of the beam need to be localized in bunches and properly phased with respect to the field so that the beam is “accelerated” Two possible designs : NC Travelling wave structures SC Standing wave cavities Linac RF acceleration concept Traveling wave V ph ≈ c and Vg < c Standing wave V ph = 0 and Vg = c mode bunches Electric field

- 20. RF Linac Overview Particle Source Linac structure : Acceleration (cavities) Transverse focusing (magnets) Electric power Vacuum Cooling RF power and controls Output beam (experiments, users, applications ...) Subsystems SNS - ORNL TTF - DESY

- 21. Energy gain and dissipated power To accelerate particles efficiently, very high electric field is required In any structure (cavity) holding an electromagnetic field, both dissipated power and stored energy scale quadratically with the fields The efficiency of a cavity depends from: Its quality factor, Q driven by the surface resistance, R s Its shunt impedance, r function of the cavity geometry and of the surface resistance, R s For efficient acceleration Q, r and r/Q must all be as high as possible U is the energy stored in the cavity P diss is the power dissipated on its surface Δ V is the voltage seen by the beam “ r over Q ” is purely a geometrical factor Good material for maximum Q and r (that is minimum P diss ) Good design for maximum r/Q L R C

- 22. Why Superconductivity in RF linacs? In normal conducting linac a huge amount of power is deposited in the copper structure, in the form of heat , that needs to be removed by water cooling (in order not to melt the structures) Dissipated power can be much higher than the power transferred into the beam for acceleration Superconductivity , at the expenses of higher complexity, drastically reduces the dissipated power and the cavities transfer more efficiently the RF power to the beam In short: NC linac: lower capital cost, but high operational cost SC linac: slightly higher capital cost, but low operational cost

- 23. Superconductivity whenever possible For a good but not perfect conductor ( ρ ≠ 0) , the fields and currents penetrate into the conductor in a small layer at the cavity surface (the skin depth , δ ) With RF fields, a SC cavity dissipate power, not all electrons are in Cooper pairs. In NC linac a huge amount of power is deposited in the copper structure: MW to have MV Pulsed operation and Low Duty Cycle SC SuperConducting NC or RT NormalConducting Nb Cu

- 24. Superconductivity whenever possible Superconductivity, drastically reduces the dissipated power. But some drawbacks Higher complexity : refrigeration and cryomodules Carnot and refrigeration plant efficiencies Higher technology : cavity treatments Simpler geometries: lower shunt impedance And two big advantages: Large bore radius : less beam losses CW or high duty cicle preferred

- 25. Index Introduction: why accelerators as source for neutrons? General principles of neutron production with accelerators What is a high power accelerator and how does it work? General layout Superconductive choice Applications of accelerator driven neutron sources Waste Transmutation (ADS) Materials studies (SNS) Fusion (IFMIF)

- 26. ADS proton beam requirements Very high duty cycle, possibly CW Energy of the order of 1 GeV, determined by neutron production rate per GeV and per proton (optimum value reached at ~1 GeV) energy dissipated in the input window (rapidly decreasing with energy, when E<few GeV) beam power from several MW up to tens of MW few MW for a “demo” plant of ~100 MWth ~20 MW for an industrial burner of ~1500 MWth Very few beam trips per year accepted if longer then 1 second No limitation for very short beam trips: << 1 second

- 28. Linac or cyclotron 1/2 Most powerful CW proton accelerators (MW-size facilities) Linacs LAMPF/LANSCE (~1970) 800 MeV 1 mA H + average current Peak H + current 16.5 mA @ 100 Hz and 625 s pulse length NC accelerator Cyclotrons PSI – separated sector (1974) Original design was for 100 A From 72 to 590 MeV ~2 mA average current Beam losses at extraction < 1 A

- 29. Linac or cyclotron 2/2 Cyclotron No remarkable R&D programs Its cost scales quadratically with the output energy Very high reliability and availability at PSI, but further improvement looks very difficult Not applicables concepts of redundancy and spare on line Linear Accelerator A worldwide R&D effort is in progress High potentiality of these machines has been proven: Sources, RFQs and SRF technology successfully operated cost per MeV is decreasing with energy Linac (except front end) has intrinsic modularity: Easy redundant and “spares on line” design

- 30. The ADS Linac Linac benefits of impressive progresses in the field of SC cavities: SC technology can be extended to proton linac down to ~ 0.5 Intrinsic modularity simplify reliability issues Redundant design strategy based on the “spare-on-line” concept Strong focusing and large beam aperture produce negligible losses The scheme generally considered consists of four different sections The proton source: proton energy 80-100 keV The Radio Frequency Quadrupole ( RFQ ): up to 5 MeV A medium energy section , either NC or SC: up to 100 MeV A high energy section made of SC elliptical rf cavities: up to final energy 1 GeV (most of the linac is here!)

- 31. Reference Linac Design Proton Source RFQ Medium energy ISCL linac 3 sections high energy SC linac 80 keV 5 MeV ~ 100 MeV 200 MeV 500 MeV >1000 MeV 3 section linac: 85/100 - 20 0 MeV, =0. 47 20 0 - 50 0 MeV, =0.65 50 0 – 1 0 00 /2000 MeV, =0.8 5 Five (six) cell elliptical cavities Quadrupole doublet focussing: multi - cavity cryostats between doublets 704.4 MHz 5 - 85/100 MeV SC linac Spoke cavities (352 MHz) Lambda/4 cavities (176 MHz) Reentrant cavities (352 MHz) or NC Drift Tube Linac (DTL) High transmission 90% 30 mA, 5 MeV (352 MHz) Microwave RF Source High current (3 5 mA) 80 keV High Energy SC Linac ISCL RFQ Source

- 32. Linac Design Accelerator design performed in the EU PDS-XADS program (5° FWP) Choice of superconducting linac Modular: same concept for Prototype and Industrial scale

- 33. Injector, an example: LEDA at LANL RFQ Concept 1.2 MW (structure) 670 kW (beam) RF Power 8 m (4 sections) Length 6.7 MeV Final Energy 100 mA (95 %) Beam current LEDA RFQ: One Section of LEDA-RFQ The LEDA-RFQ fully installed

- 34. High energy section: the test module Elliptical =0.47 cavities have been produced, vertically tested and will be equipped to be tested in an horizontal test module by INFN - LASA

- 35. The Reliability Issue The small number (few per year) of beam trips allowed during the accelerator operation, requires a detailed analysis of the accelerator availability and reliability , much deeper that in the past applications The reliability analysis of a complex system is an iterative process , which starts from a preliminary design of the whole system and its components and is followed by the development of the Reliability Block Diagram (RBD).

- 36. Some Remarks on Linac Reliability In order to meet the # of stops > 1 s The beam startup procedure for a multi MW beam will be certainly > 1 s operation with faulty components needs to be achieved Linac must tolerate single failures of most of components Procedures for “adjusting” beam transport and repairing of components without interrupting the beam while marinating acceptable losses As a consequence Components and subsystems divided in two major categories if they lead to: Failures requiring a beam stop Failures that can be repaired while the beam is on, or later… As general rules Components falling in the first category should have the highest reliability Typically passive components overdesigned and overtested Components falling in the second category should have the highest accessibility for repairing or substitution For example, this suggest the choice of a double tunnel design, with most of ancillaries situated in a free-access tunnel (Power supplies, RF generators, etc.)

- 37. Index Introduction: why accelerators as source for neutrons? General principles of neutron production with accelerators What is a high power accelerator and how does it work? General layout Superconductive choice Applications of accelerator driven neutron sources Waste Transmutation (ADS) Materials studies (SNS) Fusion (IFMIF)

- 38. SNS Guiding Principles SNS will provide high availability, high reliability operation of the world’s most powerful pulsed neutron source Research conducted at SNS will be at the forefront of biology, chemistry, physics, materials science and engineering SNS will be able to provide cold neutrons (useful for research on polymers and proteins) SNS expects 1000-2000 users per year from academia, government, and industry Flexible instrument strategy that supports both general user access and dedicated access for expert instrument teams that contribute to construction and operation of instruments

- 39. The Spallation Neutron Source

- 40. Neutron generation H- ions are produced in the front end ion source H- are accelerated to ~1GeV in Linac (NC and SC) On injection into ring 2x e- are stripped to form p Protons are accumulated and compressed into a 1 µs pulse width in the ring (~120 turns of the ring, p are traveling at ~0.9c) A kicker magnet knocks the proton pulse out of the ring orbit into the beamline that takes the p’s to the Hg target Beam losses need to be preserved below 1 W/m along the whole machine and beamlines to limit activation

- 41. Power Ramp-up Progress “We are starting to get to real beam power levels” 160 KW: ISIS Power Record

- 42. Beam Target and Neutron Moderation Spallation target Mercury was chosen for the target for several reasons it is not damaged by radiation, as are solids it has a high atomic number, making it a source of numerous neutrons (the average mercury nucleus has 120 neutrons and 80 protons) because it is liquid at room temperature, it is better able than a solid target to dissipate the large, rapid rise in temperature and withstand the shock effects arising from the rapid high-energy pulses Neutron moderation The neutrons coming out of the target must be turned into low-energy neutrons suitable for research moderated to room temperature or colder passing them through cells filled with water (to produce room-temperature neutrons) or through containers of liquid hydrogen at a temperature of 20 K (to produce cold neutrons) The moderators are located above and below the target

- 43. Layout of RF Linac 805 MHz, 0.55 MW klystron 805 MHz, 5 MW klystron 402.5 MHz, 2.5 MW klystron SRF, ß=0.61, 33 cavities 1 from CCL 186 MeV 86.8 MeV 2.5 MeV RFQ (1) DTL (6) CCL (4) SRF, ß=0.81, 48 cavities 1000 MeV (81 total powered) 379 MeV Warm Linac SCL Linac

- 44. Normal Conducting Linac CCL Systems designed and built by Los Alamos 805 MHz CCL accelerates beam to 186 MeV System consists of 48 accelerating segments, 48 quadrupoles, 32 steering magnets and diagnostics 402.5 MHz DTL was designed and built by Los Alamos Six tanks accelerate beam to 87 MeV System includes 210 drift tubes, transverse focusing via PM quads, 24 dipole correctors, and associated beam diagnostics

- 45. Superconducting Linac Designed an built by Jefferson Laboratory SCL accelerates beam from 186 to 1000 MeV SCL consists of 81 cavities in 23 cryomodules Two cavities geometries are used to cover broad range in particle velocities Cavities are operated at 2.1 K with He supplied by Cryogenic Plant Medium beta cavity High beta cavity

- 46. Others SNS Parameters Protons per pulse on target 1.5x10 14 protons Energy per pulse on target 24 kJ Average linac macropulse H- current 26 mA Linac beam macropulse duty factor 6% Front end length 7.5 m Linac length 331 m HEBT length 170 m Ring circumference 248 m RTBT length 150 m Ion type (Ring, RTBT, Target) proton Ring filling time 1.0 ms Ring revolution frequency 1.058 MHz Number of injected turns 1060 Ring filling fraction 68% Ring extraction beam gap 250 ns Maximum uncontrolled beam loss 1 W/m Number of ambient / cold moderators 1/3 Number of neutron beam shutters 18

- 47. SNS Instruments

- 48. Q- Diagram for Inelastic Instruments adapted from “Neutron Scattering Instrumentation for a High-Powered Spallation Source” R. Hjelm, et al., LA0-UR 97-1272 Momentum Distributions Itinerant Magnets Crystal Fields Molecular Vibrations Lattice Vibrations Small Molecule Diffusion Large Scale Motions Polymers and Biological Systems Tunneling Spectroscopy Electron-Phonon Interactions Hydrogen Modes Molecular Reorientation Ultracold Neutrons Fundamental Physics Slower Motions Larger Objects ARCS THERMAL CHOPPER SPECT COLD NEUTRON CHOPPER SPECT BACKSCATTERING SPECTROMETER

- 49. SNS Reflectometers R min < 5×10 -10 Q max ~ 1.5 Å -1 (Liquids) ~ 7 Å -1 (Magnetism) d min ~ 7 Å 50-100× NIST NG-1 Magnetism: vertical sample Liquids: horizontal sample

- 50. Diffraction Highest flux a short wavelengths is crucial for studies of local disorder in complex materials Nanoscale Ordered Materials Diffractometer (NOMAD)

- 51. High Pressure Cells Limit Sample Volume Pressure cell of the type to be employed on SNAP (Spallation Neutrons and Pressure) beamline

- 52. Index Introduction: why accelerators as source for neutrons? General principles of neutron production with accelerators What is a high power accelerator and how does it work? General layout Superconductive choice Applications of accelerator driven neutron sources Waste Transmutation (ADS) Materials studies (SNS) Fusion (IFMIF)

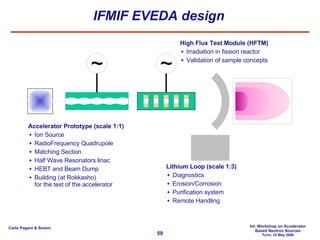

- 53. IFMIF general information IFMIF Irradiation tool to qualify advanced materials resistant to extreme radiation conditions (DEMO reactor) Requires an intense neutron flux (~ 10 17 n/s/m 2 ) at 14 MeV Neutrons are generated by stripping deutons on Li target. Deuton provided by accelerator: 2 parallel CW beams 40 MeV, 125 mA for a total power of 10 MW IFMIF-EVEDA (Engineering Validation Engineering Design Activities) Engineering design of the IFMIF facility, safety assessment for a generic site and preparation of the technical specifications for the longest delivery components Design and construction of low energy section of the first accelerator Design, construction and tests of a scale 1:3 model of the Target Facility Design, construction and tests of mock-ups of the Test Facility (high flux volume and medium flux volume). Irradiation of the test set-up to relevant irradiation dose values to check performance under real operating conditions

- 54. ITER 3 dpa/lifetime IFMIF 20-55 dpa/year Plasma Facing Materials Structural Materials Functional Materials Advanced Materials are at a critical path DEMO 30 dpa/year

- 55. IFMIF Main Objectives Neutron flux : 10 MW deuton beam power on the test module is equivalent to 1 MW/m 2 neutron beam 4.5 10 17 n/m 2 /s 3 10 -7 dpa/s for Fe Neutron spectrum : fit to probable DEMO first wall Neutron fluence accumulation : DEMO relevant (150 dpa/few years) Neutron flux gradient : about 10 % in volume Machine availability : 70 % (quasi continuous operation) Good accessibility of irradiation volume for experimentation and instrumentation neutron flux coolant flow (He) 200 50 50 [mm]

- 56. IFMIF Principles RFQ HWR HEBT Typical reactions 7 Li(d,2n) 7 Be 6 Li(d,n) 7 Be 6 Li(n,T) 4 He Source Accelerator (x 2) Test Cell Low flux (< 1 dpa/an, > 8 L) Medium flux (20 – 1 dpa/an, 6 L) Lithium target High flux (> 20 dpa/an, 0.5 L)

- 57. IFMIF “Artist View” Ion Source RF Quadrupole Post Irradiation Experiment Facilities High Energy Beam Transport Li Target Li Loop Test Modules inside Test Cells Half-wave resonators 0 20 40 m

- 58. IFMIF Accelerator A high intensity ion source, delivers a beam of deutons of 140 mA to 100 keV A RFQ (Radio Frequency Quadrupole) cavity put « in packages » and accelerate the deutons until a 5 MeV energy Elements of linear accelerator to reach the final energy (10 MeV at EVEDA, 40 MeV at IFMIF) A transport line up to the beam stop of 1,2 MW for EVEDA phase and up to the liquid lithium target of 10 MW for IFMIF

- 59. IFMIF EVEDA design Accelerator Prototype (scale 1:1) Ion Source RadioFrequency Quadrupole Matching Section Half Wave Resonators linac HEBT and Beam Dump Building (at Rokkasho) for the test of the accelerator Lithium Loop (scale 1:3) Diagnostics Erosion/Corrosion Purification system Remote Handling High Flux Test Module (HFTM) Irradiation in fission reactor Validation of sample concepts ~ ~

- 60. Accelerator Reference Design High Energy Beam Transport (HEBT) Large Bore Quad & Dipoles, 43 m long SC Half-wave resonators acceleration to 40 MeV Radio Frequency Quadrupole (RFQ) bunching & acceleration 5 MeV; MS to DTL RF Power System 175 MHz 12 RF amplifiers, 1MW CW 100 keV Injector Ion Source 140 mA D + , 100 keV LEBT transfer/match to RFQ 5 MeV 40 MeV 125 mA deuton beam Control Command 2

- 61. Injector - Conception Specifications rms emittance = 0.25 .mm.mrad (normalized ) beam current = 140 mA energy = 100 keV The injector components the ECR (Electron Cyclotron Resonance) ion source must deliver 140 mA beam current with an output energy of 100 keV the LEBT (Low Energy Beam Transport) section includes magnetic lenses (focusing and beam matching to the RFQ) beam instrumentation : charge, current, profile, size, emittance measurement the associated infrastructure: power supplies, control system, water cooling

- 62. Injector – Initial LEBT design Cone Cameras ACCT Cameras Neutron detector Emittance Monitor DC toroid on HV cable Movable ConFlat Species identification* Thermocouples *fluorescence + shifted Doppler lines analysis

- 63. Radio-Frequency Quadrupole RFQ Length 9.6 meters RFQ transmission OK 99% (w/o error) Losses above 1 MeV kept at low level 0.01 % Voltage and Power levels moderate < V > = 102 kV, P = 1200 1480 kW RF study started Cu brazing joints e-beam & laser welding alternatives under study Mechanical design in a test phase

- 64. Old design: DTL and Matching Section 1st tank parameters Conventional Alvarez technology 1 RF coupler / tank RF Frequency 175 MHz Input energy 5.02 MeV Output energy 9.02 MeV Internal length 4.67 m Internal diameter 1.074 m Number of cells 33 Total power 680 kW Power dissipation 180 kW Efficiency 73.5 % Power coupler Stem-box Cover Tuning Slug Post Coupler Drift Tube Stem Drift Tube To vacuum pump Bulk Tuner

- 65. Present design: Half-wave resonators (HWR) IFMIF/EVEDA Project Committee meeting (10-11 October 2007) Accelerator Facility Project Plan Superconducting solution: existing modules module double of the one currently operating at SOREQ L~ 5 m group cavities in long cryostats and conservative gradients Take 175 MHz HWR with big aperture 8-10-12 6 4.5 MV/m 40-50 mm SC IFMIF 5.5 MV/m 30 mm SARAF* project

- 66. Lithium target Engineering design of the target system includes thermal, thermo-structural and thermo-hydraulic analyses of the target assembly, backplate, Li components, Li loop and purification system The Lithium circuit The Lithium target Quench Tank Deuteron Beams Li Target ( T 2.5 cm, W 26 cm) EM Pump HX(Li / Organic Oil) Dump Tank (9 m 3 -Li) HX(Organic Oil / Water) 130 L/s, 250 C Cold Trap (220 C) N Hot Trap (600 C) T Hot Trap (250 C)

- 67. Principle of Test Modules 2 m D + Medium Flux Test Modules High Flux Test Module Low Flux Irradiation Tubes Lithium Target Lithium Tank Shield plug

- 68. Irradiation modules overview VIT MF-CF MF-LBV MF-TR Upper internal flange Upper reflector Lateral reflector 12 rigs Lower reflector Helium inlet duct Helium exit duct HFTM

- 69. IFMIF Medium Flux Test Module 3 independent samples in creep fatigue

- 70. Conclusions Present and future large facilities are based to a large extent on the superconducting RF linac technology that has been pioneered for the High Energy Physics machines in the last decades LEP at CERN (e+e- collider with SRF cavities) CEBAF at TJNAF (recirculated SRF linac) TESLA and ILC (next generation linear colliders proposed for precision physics in the Higgs sector after LHC discovery) SNS moved from NC design to SC after project approval and during construction Future facilities rely on SC linacs at even lower energies to benefit from SC technology

![IFMIF Main Objectives Neutron flux : 10 MW deuton beam power on the test module is equivalent to 1 MW/m 2 neutron beam 4.5 10 17 n/m 2 /s 3 10 -7 dpa/s for Fe Neutron spectrum : fit to probable DEMO first wall Neutron fluence accumulation : DEMO relevant (150 dpa/few years) Neutron flux gradient : about 10 % in volume Machine availability : 70 % (quasi continuous operation) Good accessibility of irradiation volume for experimentation and instrumentation neutron flux coolant flow (He) 200 50 50 [mm]](https://image.slidesharecdn.com/cpaganisbarbanottihigh-power-accelerators-1217236594385919-8/85/Serena-barbanotti-INFN-milano-55-320.jpg)