Chapter 4 (a) stone masonry

- 2. INTRODUCTION It may also be defined as construction of building units bounded together with mortar. The selection of the type of material (i.e. brick or stone etc) for the masonry is made keeping in view the requirement of strength, water proofing, thermal insulation ,fire resistance, durability and economy. 2

- 3. Masonry • Masonry may defined as the construction of building units bonded tougher with mortar. A. Stone masonry B. Brick masonry C. Composite masonry D. Hollow concrete block masonry E. Cavity walls F. Lintel & Arches 3

- 4. Some Important terms used in Masonry 1.HEADER: Full brick or stone laid with its length perpendicular to the face of a wall is called a "Header" • A course, in which all the bricks are laid as headers, is known as "Heading Course" or "Header course“. 4

- 5. 2.STRETCHER: • Full brick or stone laid with its length parallel to the face of a wall is called a “Stretcher" • A course, in which, all the bricks are laid as Stretchers is called a “Stretching course" or "Stretcher course". 5

- 6. 6

- 7. 3. COURSE: Each horizontal layer of bricks or stone laid in mortar is called a "course". 4. BOND: Overlapping of bricks or stones in alternate course of the wall to avoid continuous vertical joints and to bind the individual units together. 5. BRICK BATS : The pieces of bricks, cut along their length and having width equivalent to that of a full or half brick are called "Brick bats“. 7

- 8. 8

- 9. 9

- 10. 6.CLOSER Portion of a brick cut in such a manner that its one long face remains uncut. 7.QUEEN CLOSER Queen closer is a brick, which is half as wide as full brick and is made by cutting a whole brick lengthwise into two portions. 10

- 11. 11 Mitred Closer

- 12. 8. KING CLOSER: A brick which is cut in such a way that the width of one of its end is half that of full brick. 9. BEVELED CLOSER: A brick cut longitudinally along a vertical plane, starting at the middle of one end to the far corner. 10. MITRED CLOSER: It is a brick whose one end is cut splayed or mitred for the full width. 12

- 13. 13

- 14. 11.QUOIN Exterior angle or corner of a wall is known as quoin. The brick or stone laid on the corner of a wall ,as a header, it is known as quoin header. 14

- 15. 15

- 16. 12.RACKING BACK The process of stopping the unfinished end of a wall in stepped fashion. 16

- 17. 13.CORBEL Projecting stone which is provided to support the joist, truss or weather shed etc. 17

- 18. 14.CORNICE It is horizontal moulded projection provided near the top of a building or at a junction of a wall and ceiling. 18

- 19. 15.Bed Lower or bottom surface of bricks or stones in each course 16.Face Surface of a wall exposed to weather is called as face and the material used for face is called as facing. 17.Back Surface of wall ,which is not exposed to weather is called as back and the material used for back is called as backing. 18.Hearting The inner portion of a wall between facing and backing. 19

- 20. 20

- 21. 21

- 22. 19.JOINT: • The junction of adjacent bricks or stones. • The joints may be of cement mortar or lime mortar. • The joints parallel to the bed of bricks or stones are known as bed joints. 22

- 23. 20. FROG It is the depression made on the top face of the brick, for the purpose of forming a key for the mortar, which prevents the displacement of the brick above. 23

- 24. 21.BUTTRESS It is a slopping or stepped masonry projection from a tall wall, on the exterior of a wall, which are placed at intervals along the wall to carry load. 24

- 25. 22.COPING It is a Covering of stone or brick ,placed on the top of a external wall or parapet, to prevent seepage of water through joints. 25

- 26. 26

- 27. 23.SPALLS: These are the chips of stones used for filling the interstices in stone masonry. 24.PLINTH: It is the horizontal course of stone or brick provided at the base of the wall above ground level. It indicates the height of the ground level above the natural ground level. It protects the building from dampness. 25. PLINTH COURSE: It is the top most course of the plinth masonry. 27

- 28. 28

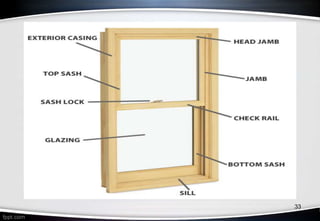

- 29. 29 26.STRING COURSE: It is a horizontal projecting course of masonry projecting out of the face of the wall for shedding rain water off the face. It imparts an aesthetic appearance to the structure and is generally provided at every floor level. 27. SILL: It is a horizontal member of stone, concrete or wood, employed for the purpose of shedding off rain water from the face of wall immediately below the window opening. It gives support to the vertical members of a wooden window frame. 28. LINTEL: It is a horizontal member of stone, brick, wood, iron or RCC used to support the masonry or load above an opening.

- 30. 30

- 31. 31

- 32. 29. JAMBS: These are the vertical sides of an opening for doors and windows. These may be plain or splayed or may be provided with recesses to receive the frames of doors and windows. 30. REVEALS: These are exposed vertical surfaces left on the sides of an opening after the door or window frame had been fitted in position. 31.BLOCKING COURSE: It is a top most course of stone masonry provided immediately above the cornice to prevent the tendency of the cornice to overturn. It also adds to the aesthetics of the cornice. 32

- 33. 33

- 34. 34

- 35. 32. PERPEND: It is a vertical joint on the face of a wall directly over vertical joints in an alternate course. 34. ARCH: A mechanical arrangement of wedge-shaped blocks of stone or brick arranged in the form of a curve supporting the masonry or load above an opening. 35. PARAPET: It is a term applied to a low wall built around a flat roof to act as a protective solid balustrade for the users of the terrace. 35 33.TEMPLATE: Pieces of stones placed under the end of a beam to distribute the load over a greater area.

- 36. 36

- 37. 37 36. WEATHERING: Weathering is the term applied to the beveled top surface of a stone. 37. GABLE: It is a triangular shaped portion of masonry at the end of a sloped roof. 39.COLUMNS: It is an isolated vertical load bearing member whose width does not exceed four times its thickness. 40. PIER: It is a vertical member of stone or brick masonry constructed to support an arch, beam or lintel etc. 38. THRESHOLDS: The arrangement of steps provided from ground level to reach plinth level on external doors and verandah is termed as thresholds.

- 38. 38

- 40. When a binding material, a fine aggregate and water are mixed together in suitable proportions , they form an easily workable paste which is termed as Mortar. When a binding material, ( a fine & a coarse aggregate) and are mixed in suitable proportions , they form an easily workable mix which is termed as plastic, wet or green concrete. MATERIAL FOR STONE MASONARY 40

- 41. TYPES OF MORTAR & THEIR USES Cement mortar: •The paste is prepared by mixing cement and sand in suitable proportions in addition to water. •The general proportion is 1 part of cement to 2-8 parts clean sand. These mortars must be use within half an hour, i.e.; before initial setting time of the cement. •This type is used for all engineering works where high strength is desired such as load bearing walls, deep foundations, flooring etc. 41

- 42. Lime mortar: •The paste is prepared by mixing lime and sand or surkhi in suitable proportions in addition to water. •If surkhi is to be added in lime mortar the equal proportions of sand and surkhi should be mixed with lime. These mortars are inferior to cement mortars in strength as well as water tightness. •These mortars should not be used for underground works as they set in the presence of carbon dioxide and break up in damp conditions. This type is used for construction work above ground level i.e. exposed positions. 42

- 43. Materials used for stone masonry: The natural stones used in building can be classified to their origin as: 1. Igneous: are formed by cooling the molten lava on or inside the earth’s surface during the volcanic eruption. The portion of lava, which comes outside the surface, cools, quickly and forms the rocks of non crystalline nature called as basalt. The rest of the portion which remains inside the earth undergoes cooling at a slow rate and results in formation of rock of crystalline variety known as granite. Rock, that is removed from its natural site and generally, cut or dressed and then finished for building purposes, is called "Stone" and the art of building the structure with stones as constructional units is called "Stone masonry". 43 STONE

- 44. 44

- 45. 45 2. Sedimentary: are formed by gradual deposition of disintegrated rocks , vegetable matter and clay at the bottom of rivers, lakes or sea. These are also called stratified because these rocks are formed in layer. Limestone & sand stone belong to this category of rocks. 3. Metamorphic: are formed from igneous or sedimentary rocks as a result of the action of the earth movements, temperature changes, liquid pressures, etc. The resultant mass may have a foliated structure, e.g. slate, gneiss, schist and e.g. marble, quartzite and serpentine.

- 46. 46

- 47. The common types of stones available are: 1.Granite: It consists of grains of quartz in combination with feldspar and mica. These are the hardest types of stones and difficult to work with. They are available in various colours ranging from white to green. These are used for the construction of steps, walls, sills and as facing over other masonry. 2. Sandstone: They are made of quartz cemented by a matrix of silica. They also contain mica, feldspar and oxides of iron. The colours of sandstones are due to the presence other minerals in them. They can be worked easily to take any ornamental shape. Their texture being coarse, they give a good appearance when used along with brick masonry. 47

- 48. 48 3.Limestone: These are calcareous rocks and consist of carbonate of lime. They are available in various colors and easy to work with. They are used for walls, floors, steps, etc. 4.Marbles: They are like limestone, are calcareous rocks and consist and consist of carbonate of lime. They are very useful material for flooring and monumental structures. Marble are available in various colors and can very good polish. 5.Slates: These are available in hilly areas and are metamorphic rocks. Generally they have a black colour. Slates can be split in thin sheets along their bedding planes. They mostly used for roofing work.

- 49. STONE MASONRY 49 Main types of stone masonry:- (1) Rubble masonry (2) Ashlar masonry Stone masonry is used for the construction of walls, columns, lintels, arches, beams, etc., of a building. Stones are abundantly available in nature and when cut and dressed to proper shapes, they provide an economical material for the construction of various parts of building.

- 50. Stone masonry Rubble masonry 1. Un-coursed or random rubble masonry. 2.Coursed rubble masonry 3. Dry rubble masonry Ashlar masonry 1. Ashlar Fine masonry 2. Ashlar Rough Tooled 3. Rock or rustic or Quarry Faced 4. Ashlar Chamfered 5. Ashlar Facing 50

- 51. 1. Rubble Masonry: The stone masonry in which either undressed or roughly dressed stone are laid in a suitable mortar is called rubble masonry. In this masonry the joints are not of uniform thickness. Rubble masonry is further sub-divided into the following three types: Random rubble masonry Squared rubble masonry Dry rubble masonry. 1. Random rubble masonry: The rubble masonry in which either undressed or hammer dressed stones are used is called random rubble masonry. Further random rubble masonry is also divided into the following three types. 51

- 52. a. Un coursed random rubble masonry: The random rubble masonry in which stones are laid without forming courses is known as un coursed random rubble masonry. This is the roughest and cheapest type of masonry and is of varying appearance. • The stones used in this masonry are of different sizes and shapes. before lying, all projecting corners of stones are slightly knocked off. Vertical joints are not plumbed, joints are filled and flushed. • Large stones are used at corners to increase their strength. Suitability: Used for construction of walls of low height in case of ordinary buildings. 52

- 53. 1.UN-COURSED or RANDOM RUBBLE MASONRY. 53

- 54. b. Coursed random rubble masonry: The random rubble masonry in which stones are laid in layers of equal height is called random rubble masonry. • In this masonry, the stones are laid in somewhat level courses. Headers of one coursed height are placed at certain intervals. The stones are hammer dressed. Suitability: Used for construction of residential buildings, go downs, boundary walls etc. 54

- 56. c. Dry rubble masonry: The rubble masonry in which stones are laid without using any mortar is called dry rubble masonry or sometimes shortly as "dry stones". It is an ordinary masonry and is recommended for constructing walls of height not more than 6m. In case the height is more, three adjacent courses are laid in squared rubble masonry mortar at 3m intervals. Suitability: Used for non-load bearing walls such as compound wall etc. 56

- 58. ASHLAR MASONRY • The stone masonry in which finely dressed stones are laid in cement or lime mortar is known as ashlars masonry. In this masonry are the courses are of uniform height, all the joints are regular, thin and have uniform thickness. • This type of masonry is much costly as it requires dressing of stones. Suitability: This masonry is used for heavy structures, architectural buildings, high piers and abutments of bridges. 58

- 59. 1. ASHLAR FINE MASONRY • Each stone is cut to uniform size and shape with all sides rectangular, so that the stone gives perfectly horizontal and vertical joints with adjoining stone. • Ht of courses > 30 cm • May be of alternate H & S 59

- 60. 2. ASHLAR ROUGH TOOLED MASONRY 60 The beds and sides are finely chisel-dressed. But the face is made rough by means of tools. A strip, about 25mm wide and made by means of chisel is provided around the perimeter of the rough dressed face of each stone. Thickness of joint should not more than 6 mm.

- 61. 3. ASHLAR ROCK OR RUSTIC OR QUARRY FACED 61 A strip is provided around the perimeter of every stone. But the remaining portion of the face is left in the same form as received from quarry. Projection on exposed face is restricted to 75 mm.Thickness of joint –up to 10 mm.

- 62. 4. ASHLAR CHAMFERED MASONARY 62 The strip is chamfered or beveled at an angle of 45 degrees by means of chisel for a depth of about 25mm.

- 63. 5. ASHLAR FACING MASONARY 63 If the backing is of Rubble masonary, It is called “Rubble Ashlar" and if the backing is of brick work the masonary is termed as “Brick Ashlar”.

- 64. Ashlar facing: Ashlar facing is the best type of ashlars masonry. Since this is type of masonry is very expensive, it is not commonly used throughout the whole thickness of the wall, except in works of great importance and strength. For economy the facing are built in ashlars and the rest in rubble. 64

- 65. JOINTS IN STONE MASONRY 1.BUTT JOINT:- Dressed edges of two stones are placed side by side. 65

- 66. 2.REBATED OR LAPPED JOINT:- Provided in arches, gables etc. Used in slopes to prevent the movement of stones. 66

- 67. 3.TABLE OR BED JOINT:- Provided in sea wall to prevent the lateral movement of stones. Ht of projection is 30-40 mm & width is 1/3 w of stone. 67

- 68. 4.CRAMPED JOINT:- The metal cramps are used to prevent the tendency of the joint to be pulled apart. The dovetail shape holes are made in both the stones to be joined. After placing the cramp in position, the joint is grouted and covered with cement, lead or asphalt. 68

- 69. 5.PLUG JOINT:- The plug joint is an Alternative of cramped joint. It consist of plug holes of dovetail shape in plan and cut below the top surface of stones. The stones are jointed by filling the holes with cement. 69

- 70. 6.DOWEL JOINT:- This type of joint is used to ensure the Stability of stones against sliding or displacement. Dowels made of slate, copper, brass . The dowels are set in cement mortar. 70

- 71. 7.RUSTICATED JOINT:- This type of joints are generally used in plinths or masonry in lower storey's of buildings to give the structure massive appearance. 71

- 72. 8.JOGGLE JOINT:- It is made of metal or slate, which is placed in between the groove provided in two adjacent stones, to prevent sliding along the side joints. 72

- 73. LIFTING APPLIANCES During masonry construction, small size stones are handled manually, but Large size stones are lifted and then placed in position with the help of various lifting appliances. 1.LEWIS 2.NIPPERS 73

- 74. 1.LEWIS A. Pin Lewis:- It consist of Pair of pointed steel rods are inserted into the inclined holes made in the stone-block. When the stone is lifted with the help of rope or chain ,the inclined steel rods are strongly tighten in the holes. 74

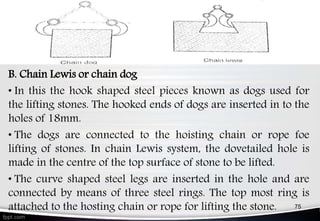

- 75. LIFTING APPLIANCES B. Chain Lewis or chain dog • In this the hook shaped steel pieces known as dogs used for the lifting stones. The hooked ends of dogs are inserted in to the holes of 18mm. • The dogs are connected to the hoisting chain or rope foe lifting of stones. In chain Lewis system, the dovetailed hole is made in the centre of the top surface of stone to be lifted. • The curve shaped steel legs are inserted in the hole and are connected by means of three steel rings. The top most ring is attached to the hosting chain or rope for lifting the stone. 75

- 76. C. Three legged Lewis 76

- 77. 2.NIPPERS The Pointed ends of nippers are inserted in hole made little below the stone top face & stone block is raised by attaching a chain to assembly. 77

- 78. 78