CNC Programmingmodifies examination 1

- 1. CNC PROGRAMMING & MACHININGCNC PROGRAMMING & MACHINING PREPARED BYPREPARED BY

- 5. DEFINITIONDEFINITION • InIn CNCCNC ((Computer Numerical ControlComputer Numerical Control),), thethe instructions are stored as a program in ainstructions are stored as a program in a micro-computer attached to the machine.micro-computer attached to the machine. The computer will also handle much of theThe computer will also handle much of the control logic of the machine, making itcontrol logic of the machine, making it more adaptable than earlier hard-wiredmore adaptable than earlier hard-wired controllers.controllers.

- 6. Utilization of computers inUtilization of computers in manufacturing applications hasmanufacturing applications has proved to be one of the mostproved to be one of the most significant developments over thesignificant developments over the last couple of decades in helping tolast couple of decades in helping to improve the productivity andimprove the productivity and efficiency of manufacturingefficiency of manufacturing systems.systems.

- 8. CNC SYSTEM ELEMENTSCNC SYSTEM ELEMENTS A typical CNC system consists of thA typical CNC system consists of thee following six elementsfollowing six elements • Part programPart program • Program input deviceProgram input device • Machine control unitMachine control unit • Drive systemDrive system • Machine toolMachine tool • Feedback systemFeedback system

- 9. 20042004 99 NC SYSTEM ELEMENTSNC SYSTEM ELEMENTS

- 10. OPERATIONAL FEATURES ofOPERATIONAL FEATURES of CNC MACHINESCNC MACHINES

- 11. CNC MACHINE TOOLCNC MACHINE TOOL Part drawing & Part Programming Input Part Programming By Tape / MDI / Computer

- 12. How CNC Works • Controlled by G and M codes. • These are number values and co- ordinates. • Each number or code is assigned to a particular operation. • Typed in manually to CAD by machine operators. • G&M codes are automatically generated by the computer software..

- 13. Features of CNC Machinery • The tool or material moves. • Tools can operate in 1-5 axes. • Larger machines have a machine control unit (MCU) which manages operations. • Movement is controlled by a motors (actuators). • Feedback is provided by sensors (transducers) • Tool magazines are used to change tools

- 14. Tools • Most are made from high speed steel (HSS), tungsten carbide or ceramics. • Tools are designed to direct waste away from the material. • Some tools need coolant such as oil to protect the tool and work.

- 15. Tool Paths, Cutting and Plotting Motions • Tool paths describes the route the cutting tool takes. • Motion can be described as point to point, straight cutting or contouring. • Speeds are the rate at which the tool operates e.g. rpm. • Feeds are the rate at which the cutting tool and work piece move in relation to each other. • Feeds and speeds are determined by cutting depth, material and quality of finish needed. e.g. harder materials need slower feeds and speeds. • Rouging cuts remove larger amounts of material than finishing cuts. • Rapid traversing allows the tool or work piece to move rapidly when no machining is taking place.

- 16. CNC Programming Basics • CNC instructions are called part program commands. • When running, a part program is interpreted one command line at a time until all lines are completed. • Commands, which are also referred to as blocks, are made up of words which each begin with a letter address and end with a numerical value.

- 17. Programming Key Letters • O - Program number (Used for program identification) • N - Sequence number (Used for line identification) • G - Preparatory function • X - X axis designation • Y - Y axis designation • Z - Z axis designation • R - Radius designation • F – Feed rate designation • S - Spindle speed designation • H - Tool length offset designation • D - Tool radius offset designation • T - Tool Designation • M - Miscellaneous function

- 18. Explanation of commonly used G codes • G00 – Preparatory code to control final position of the tool and not concerned with the path that is followed in arriving at the final destination. • G01 – Tool is required to move in a straight line connecting current position and final position. Used for tool movement without any machining- point to point control. (linear interpolation) • G02 – Tool path followed is along an arc specified by I, J and K codes.( circular interpolation)

- 19. Table of Important G codes G00 Rapid Transverse G01 Linear Interpolation G02 Circular Interpolation, CW G03 Circular Interpolation, CCW G17 XY Plane,G18 XZ Plane,G19 YZ Plane G20/G70 Inch units G21/G71 Metric Units G40 Cutter compensation cancel G41 Cutter compensation left G42 Cutter compensation right G43 Tool length compensation (plus) G43 Tool length compensation (plus) G44 Tool length compensation (minus) G49 Tool length compensation cancel G80 Cancel canned cycles G81 Drilling cycle G82 Counter boring cycle G83 Deep hole drilling cycle G90 Absolute positioning G91 Incremental positioning

- 20. Table of Important M codes • M00 Program stop • M01 Optional program stop • M02 Program end • M03 Spindle on clockwise • M04 Spindle on counterclockwise • M05 Spindle stop • M06 Tool change • M08 Coolant on • M09 Coolant off • M10 Clamps on • M11 Clamps off • M30 Program stop, reset to start

- 21. Optimum machine programming requires consideration of certain machine operating parameters including: • Positioning control • Compensations • Special machine features Positioning control is the ability to program tool and machine slide movement simultaneously along two or more axes. Positioning may be for point-to-point movement or for contouring movement along a continuous path. Contouring requires tool movement along multiple axes simultaneously. This movement is referred to as “Interpolation” which is the process of calculating intermediate values between specific points along a programmed path and outputting those values as a precise motion. Interpolation may be linear having just a start and end point along a straight line, or circular which requires an end point, a center and a direction around the arc. Program Command Parameters

- 22. CNC Programming Basics • Each letter address relates to a specific machine function. “G” and “M” letter addresses are two of the most common. A “G” letter specifies certain machine preparations such as inch or metric modes, or absolutes versus incremental modes. • A “M” letter specifies miscellaneous machine functions and work like on/off switches for coolant flow, tool changing, or spindle rotation. Other letter addresses are used to direct a wide variety of other machine commands.

- 23. • Programming consists of a series of instructions in form of letter codes • Preparatory Codes: • G codes- Initial machining setup and establishing operating conditions • N codes- specify program line number to executed by the MCU • Axis Codes: X,Y,Z - Used to specify motion of the slide along X, Y, Z direction • Feed and Speed Codes: F and S- Specify feed and spindle speed • Tool codes: T – specify tool number CNC programming

- 24. CNC programming Important things to know: • Coordinate System • Units, incremental or absolute positioning • Coordinates: X,Y,Z, RX,RY,RZ • Feed rate and spindle speed • Coolant Control: On/Off, Flood, Mist • Tool Control: Tool and tool parameters

- 25. Rules for programmingRules for programming Block Format N135 G01 X1.0 Y1.0 Z0.125 F5 Sample Block • Restrictions on CNC blocks • Each may contain only one tool move • Each may contain any number of non-tool move G-codes • Each may contain only one feed rate • Each may contain only one specified tool or spindle speed • The block numbers should be sequential • Both the program start flag and the program number must be independent of all other commands (on separate lines) • The data within a block should follow the sequence shown in the above sample block

- 26. 2626 HardwareHardware Configuration of NCConfiguration of NC MachineMachine Machine Control Unit (MCU) the brain of the NC machine. The Data Processing Unit (DPU) reads the part program. The Control Loop Unit (CLU) controls the machine tool operation.

- 27. Point to Point and Tool Paths

- 28. 2828 Point-to-Point Tool MovementsPoint-to-Point Tool Movements Point-to-point control systems cause the tool to move to a point on the part and execute an operation at that point only. The tool is not in continuous contact with the part while it is moving. Drilling, reaming, punching, boring and tapping are examples of point-to- point operations.

- 29. 2929 Continuous-Path Tool MovementsContinuous-Path Tool Movements Continuous-path controllers cause the tool to maintain continuous contact with the part as the tool cuts a contour shape. These operations include milling along any lines at any angle, milling arcs and lathe turning.

- 30. 3030 Loop Systems for Controlling ToolLoop Systems for Controlling Tool MovementMovement Open Loop System Uses stepping motor to create movement. Motors rotate a fixed amount for each pulse received from the MCU. The motor sends a signal back indicating that the movement is completed. No feedback to check how close the actual machine movement comes to the exact movement programmed.

- 31. 3131 Loop Systems for Controlling ToolLoop Systems for Controlling Tool MovementMovement Closed Loop System AC, DC, and hydraulic servo-motors are used. The speed of these motors are variable and controlled by the amount of current or fluid. The motors are connect to the spindle and the table. A position sensor continuously monitors the movement and sends back a single to Comparator to make adjustments.

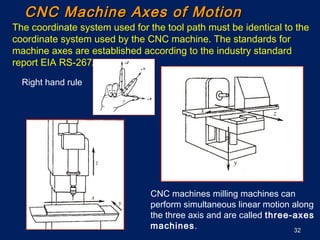

- 32. 3232 CNC Machine Axes of MotionCNC Machine Axes of Motion The coordinate system used for the tool path must be identical to the coordinate system used by the CNC machine. The standards for machine axes are established according to the industry standard report EIA RS-267A. Right hand rule CNC machines milling machines can perform simultaneous linear motion along the three axis and are called three-axes machines. Horizonta l milling machine

- 33. 3333 CNC Machine Axes of MotionCNC Machine Axes of Motion Coordinate system for a Lathe

- 34. 3434 CNC Machine Axes of MotionCNC Machine Axes of Motion More complex CNC machines have the capability of executing additional rotary motions (4th and 5th axes).

- 35. 3535 CNC Machine Axes of MotionCNC Machine Axes of Motion Five-axis machine configurations

- 36. X + X - Y + Y - Z + Z - DEFINING THE AXIS OF CNC MACHINING CENTREDEFINING THE AXIS OF CNC MACHINING CENTRE X0.Y0.Z0

- 37. X0,Z0 X+ X - Z+Z - AXIS DEFINITION OF CNC LATHEAXIS DEFINITION OF CNC LATHE

- 38. Machine Table Work piece MachineX Y Z Coordinate SystemCoordinate System Machine Vs Work pieceMachine Vs Work piece Reference Point X0,Y0,Z0 Work piece Reference Point X0,Y0,Z0

- 39. MACHINE SPINDLE STANDARD TOOL BAR LENGTH 200 mm MACHINE TABLE SLIP GAUGE(25 mm) Z 25 mm Z 200+25 mm ZZ AXIS MACHINE REFERENCE POINT SETTINGAXIS MACHINE REFERENCE POINT SETTING

- 40. X1 Z1 MEASURED VALUE X0,Z0 MACHINE REFERENCE POINT SHIFTING MACHINE REFERENCE POINTSHIFTING MACHINE REFERENCE POINT TOTO WORK PIECE REFERENCE POINT IN CNC LATHEWORK PIECE REFERENCE POINT IN CNC LATHE

- 41. CODE FOR SHIFTING MACHINE REFERENCE POINTCODE FOR SHIFTING MACHINE REFERENCE POINT TO WORK PIECE REFERENCE POINTTO WORK PIECE REFERENCE POINT OROR ZERO OFFSETZERO OFFSET G54,G55, G56,G57,G59,G60ZERO OFFSET are CANCELLATION OF ZERO OFFSET IS G53 G54 X,Y,Z Note: The Values of X,Y,Z are difference between machine reference point to work piece reference point EXAMPLE

- 42. R1 R2 End mill Work Piece Manual Part Programming Vs Computer ProgrammingManual Part Programming Vs Computer Programming R1>R2

- 43. Coordinate Values in Absolute / IncrementalCoordinate Values in Absolute / Incremental Absolute Incremental Y Y X X 20 40 20 20 30 3030 60 A B A B

- 44. Circle Part of Circle Straight Line Starting point & Ending point are same Starting point Ending point Starting point Ending point Ending point Start point or or Commonly used GeometryCommonly used Geometry Centre of circle Ending point Starting point or or I.J X1.Y1 X1.Y1 I.J G00 OR G01 X2,y2

- 45. CIRCULAR MOTION COUNTERCLOCKWISE DIRECTION CIRCULAR MOTION CLOCKWISE DIRECTION GO3 GO2 Start point End point Start point End point CIRCULAR MOTIONCIRCULAR MOTION

- 46. Z X Y G02 G03G18 G19 G03 G02 G 02 G03G17 Circular Interpolation With Respect to plane selectionCircular Interpolation With Respect to plane selection

- 47. 4747 Basic Concept of PartBasic Concept of Part ProgrammingProgramming Part programming contains geometric data about the part and motion information to move the cutting tool with respect to the work piece. Basically, the machine receives instructions as a sequence of blocks containing commands to set machine parameters; speed, feed and other relevant information. A block is equivalent to a line of codes in a part program. N135 G01 X1.0 Y1.0 Z0.125 T01 F5.0 Coordinates Special function Block number G-code Tool number

- 48. 4848 Basic Concept of PartBasic Concept of Part ProgrammingProgramming Preparatory command (G code) The G codes prepare the MCU for a given operation, typically involving a cutter motion. G00 rapid motion, point-to-point positioning G01 linear interpolation (generating a sloped or straight cut) G06 parabolic interpolation (produces a segment of a parabola) G17 XY plane selection G20 circular interpolation G28 automatic return to reference point G33 thread cutting

- 49. 4949 Basic Concept of PartBasic Concept of Part ProgrammingProgrammingMiscellaneous commands (M code) M00 program stop M03 start spindle rotation (cw) M06 tool change M07 turn coolant on Feed commands (F code) Used to specify the cutter feed rates in inch per minute. Speed commands (S code) Used to specify the spindle speed in rpm. Tool commands (T code) Specifies which tool to be used, machines with automatic tool changer.

- 50. Mechanical EngineeringMechanical Engineering DepartmentDepartment 5050 CNC Machine Tool PositioningCNC Machine Tool Positioning ModesModesWithin a given machine axes coordinate system, CNC can be programmed to locate tool positions in the following modes; incremental, absolute, or mixed.

- 51. 5151 Manual Part ProgrammingManual Part Programming Example:Example:

- 52. Mechanical EngineeringMechanical Engineering DepartmentDepartment 5252 Example of a part programExample of a part program Loading tool N003 G00 X0.0 Y0.0 Z40.0 T01 M06 Tool change Rapid motion Positioning tool at P1 N004 G01 X75.0 Y0.0 Z-40.0 F350 M03 M08 Start spindle Start coolant Linear interpolation N001 G91 (incremental) N002 G71 (metric)

- 53. 5353 Manual Part ProgrammingManual Part Programming Answer:Answer: N001 G91N001 G91 N002 G71N002 G71 N003 G00 X0.0 Y0.0 Z40.0 T0.1 M06N003 G00 X0.0 Y0.0 Z40.0 T0.1 M06 N004 G01 X65.0 Y0.0 Z-40.0 F950 S717 M03N004 G01 X65.0 Y0.0 Z-40.0 F950 S717 M03 N005 G01 X10.0 F350 M08N005 G01 X10.0 F350 M08 N006 G01 X110.0N006 G01 X110.0 N007 G01 Y70.0N007 G01 Y70.0 N008 G01 X-40.86N008 G01 X-40.86 N009 G02 X-28.28 Y0.0 I14.14 J5.0N009 G02 X-28.28 Y0.0 I14.14 J5.0 N010 G01 X-40.86N010 G01 X-40.86 N011 G01 Y-70.0N011 G01 Y-70.0 N012 G01 X-75.0 Y0.0 Z40.0 F950 M30N012 G01 X-75.0 Y0.0 Z40.0 F950 M30

- 54. 5454 Computer-Assisted PartComputer-Assisted Part ProgrammingProgramming • Identify the part geometry, cutter motions, speeds,Identify the part geometry, cutter motions, speeds, feeds, and cutter parameter.feeds, and cutter parameter. • Code the above information using ATP.Code the above information using ATP. • Compile to produce the list of cutter movements andCompile to produce the list of cutter movements and machine control information (Cutter Location datamachine control information (Cutter Location data file, CL).file, CL). • Use post-processor to generate machine controlUse post-processor to generate machine control data for a particular machine. This is the same asdata for a particular machine. This is the same as NC blocks.NC blocks. Automatically Programmed Tools (ATP) language is the most comprehensive and widely used program. The language is based on common words and easy to use mathematical notations

- 55. NomenclaturNomenclatur ee ToolTool NoNo RadiusRadius XX LengtLengt hh ZZ ENDMILLENDMILL T01T01 20.0020.00 150.0150.0 00 DRILLDRILL T02T02 00 100.0100.0 00 BORING ToolBORING Tool T03T03 125.0125.0 00 Starting point Ending point G41 Starting point G42 Required tool path Actual tool path CRC CUTTER RADIUS COMPENSATIONCRC CUTTER RADIUS COMPENSATION G41& G42G41& G42

- 56. Tool Starting point Arc ending point I, J LEAD X1,(Y1+LEAD) X2,Y2 Arc starting pointX1,Y1 Cutter compensation executed Programmed path Cutter moving path Centre of arc Radius Compensation ExecutionRadius Compensation Execution G42

- 57. R1 R2 Point1 Point2 N20 G54 X (point1 value) Y(point1 value) Z500 N30 T0101 M06 N60 G02X-(R1value) Y-(R1value) I0 J-(R1value) N90 G53 G00 G40 X(point1 value) Y(point1 value) N55 G01 Z-500 F500 %N9001 N10 G00 G90 N40 G01 G42X (point2 value) Y(point2 value) N50 G91 N70 G03 X0 Y0 I0J-(R2value) N80 G02X-(R1value) Y+(R1value) I0 J+(R1value) Greater than Cutter Radius N35 M03 N95 M05 CIRCULAR INTERPOLATION PROGREMMECIRCULAR INTERPOLATION PROGREMME

- 58. R1 R2 Point1 Point2 N20 G54 X (point1 value) Y(point1 value) Z500 N30 T0101 M06 N90 G53 G00 G40 X(point1 value) Y(point1 value) N55 G01 Z-500 F500 %N9001 N10 G00 G90 N40 G01 G42X (point2 value) Y(point2 value) N50 G91 N70 G03 X0 Y0 I0J-(R2value) N80 G02X-(R1value) Y+(R1value) I0 J+(R1value) Greater than Cutter Radius N65 E0205 N60 G02X-(R1value) Y-(R1value) I0 J-(R1value) N85 G01 G90 Z500 CIRCULAR INTERPOLATION PROGREMMECIRCULAR INTERPOLATION PROGREMME

- 59. THREAD CUTTING PROGRAMMETHREAD CUTTING PROGRAMME Greater than Cutter RadiusR1 R2 R1 Greater than Cutter Radius R2 Circular Interpolation G90 G00 X (Point1 value) Y (Point1 value) Z0 D01 G41 G01 X (Point 2value) Y (Point2 value) G91 G03 X-(R1value) Y+(R1value) I-(R1value) J 0 G03 X0 Y0 I0 J-(R2value) Z -(Pitch value) G03 X-(R1value) Y-(R1value) I0 J-(R1value) G90 G00 Z500 G40 Threading tool Point 1 Point2

- 60. 10 20 30 60 M10, 4Nos 10mm depth Tapped as shown PointsPoints XX YY 11 10.0010.00 30.0030.00 22 20.0020.00 30.0030.00 33 10.0010.00 60.0060.00 44 20.0020.00 60.0060.00 N40 G81 M03 X10.00 Y30.00 R200S500 F300 Z-300 N50 G22 X9008 N60 G22 X9005 N30 T0101 M06 N30 T0102 M06 N40 G81 M03 X10.00 Y30.00 R200 S500 F300 Z-1500 N50 G22 X9008 N60 G22 X9005 N40 G84 M03 X10.00 Y30.00 R200 S40 F100 Z-1500 N50 G22 X9008 N60 G22 X9005N10 X2000 Y3000 N20 X1000 Y6000 N30 X2000 Y6000 % N9008 Sub Programme % N9005 Sub Programme N10 G80 G00 X50000 Y50000 DRILLING PROGRAMMEDRILLING PROGRAMME Centre drilling Core drilling M10 Tapping %N9001 N10 G54 N20 G22 X9005 N70 G53 M05

- 61. #102 = 12 #103 = 90 #110 = 1 #104 = #103 + #102 N10 #105= 270 *COS(#104) #106=270*SIN(#104) IF( #110 EQ 8) GOTO30 IF (#110 EQ 15) GOTO30 IF (#110 EQ 22) GOTO30 G81 x#105 Y#106 Z-8 R10 F150 #110=#110+1 #104 = #104 +#102 GOTO10 N20 G80 N30 IF(#110GT30) GOTO20 Programme using Mathematical FunctionProgramme using Mathematical Function

- 62. X0.Z0 X1.Z1 X4.Z4 G71 P10 Q60 U200 W200 D300 e100 G00 X4+500 Z+200 N10 G00 X0 G42 G01 Z0 X1 Z1 G03 X2 Z2 R400 G01X3Z3 N60 X4 Z4 G40 ROUGH TURNING CYCLE AT CNC LATHEROUGH TURNING CYCLE AT CNC LATHE X3.Z3 X2.Z2

- 63. 6363 Direct numerical controlDirect numerical control

- 64. CNC Machines- Advantages/Disadvantages Advantages: • High Repeatability and Precision e.g. Aircraft parts • Volume of production is very high • Complex contours/surfaces need to be machined. E.g. Turbines • Flexibility in job change, automatic tool settings, less scrap • More safe, higher productivity, better quality • Less paper work, faster prototype production, reduction in lead times Disadvantages: • Costly setup, skilled operators • Computers, programming knowledge required • Maintenance is difficult

- 65. CNC Lathe • Automated version of a manual lathe. • Programmed to change tools automatically. • Used for turning and boring wood, metal and plastic.

- 66. CNC Milling Machine • Has 3 to 5 axes. • Used for wood, metal and plastic. • Used to make 3D prototypes, moulds, cutting dies, printing plates and signs.

- 67. 20042004 6767 ADVANTAGES of CNCADVANTAGES of CNC • ProductivityProductivity Machine utilisation is increased becauseMachine utilisation is increased because more time is spent cutting and less time ismore time is spent cutting and less time is taken by positioning.taken by positioning. Reduced setup time increases utilisationReduced setup time increases utilisation too.too.

- 68. 20042004 6868 ADVANTAGES of CNCADVANTAGES of CNC • QualityQuality Parts are more accurate.Parts are more accurate. Parts are more repeatable.Parts are more repeatable. Less waste due to scrap.Less waste due to scrap.

- 69. 20042004 6969 ADVANTAGES of CNCADVANTAGES of CNC • Reduced inventoryReduced inventory Reduced setup time permits smallerReduced setup time permits smaller economic batch quantities.economic batch quantities. Lower lead time allows lower stock levels.Lower lead time allows lower stock levels. Lower stock levels reduce interest chargesLower stock levels reduce interest charges and working capital requirements.and working capital requirements.

- 70. 20042004 7070 ADVANTAGES of CNCADVANTAGES of CNC • Machining Complex shapesMachining Complex shapes Slide movements under computer control.Slide movements under computer control. Computer controller can calculate steps.Computer controller can calculate steps. First NC machine built 1951 at MIT forFirst NC machine built 1951 at MIT for aircraft skin milling.aircraft skin milling.

- 71. 20042004 7171 ADVANTAGES of CNCADVANTAGES of CNC • Management ControlManagement Control CNC leads to CADCNC leads to CAD Process planningProcess planning Production planningProduction planning

- 72. 20042004 7272 DRAWBACKS of CNCDRAWBACKS of CNC • High capital costHigh capital cost Machine tools cost $30,000 - $1,500,000Machine tools cost $30,000 - $1,500,000 • Retraining and recruitment of staffRetraining and recruitment of staff • New support facilitiesNew support facilities • High maintenance requirementsHigh maintenance requirements • Not cost-effective for low-level production onNot cost-effective for low-level production on simple partssimple parts • As geometric complexity or volume increasesAs geometric complexity or volume increases CNC becomes more economicalCNC becomes more economical • Maintenance personnel must have bothMaintenance personnel must have both mechanical and electronics expertisemechanical and electronics expertise

- 73. 20042004 7373 INDUSTRIES MOST AFFECTEDINDUSTRIES MOST AFFECTED by CNCby CNC • AerospaceAerospace • MachineryMachinery • ElectricalElectrical • FabricationFabrication • AutomotiveAutomotive • InstrumentationInstrumentation • Mold makingMold making