How can lean alleviate the overloading of qa

- 1. How can LEAN alleviate the overloading of QA? -Dave Ungar, PfMP, PMP CSQE, CQA @daveungar225 QA is all too familiar with this problem: Too much is dropped on QA at the end of a development cycle, causing a logjam, not enough time to sufficiently test. Where you have an agile environment or a more linear development methodology, this phenomenon can still occur – the last steps of the process are always at risk. What is Lean and how would it help? How do we know if it’s helping? And if all of that sounds good, how do we convince management to start being Lean, and how do we start? How can LEAN alleviate the overloading of QA? QA is all too familiar with the problem (ie – too much coming at QA at the end of a cycle, causes a logjam, run out of time) How would Lean process help? (what is Lean, what’s the theory?) What to measure? – How do metrics have an effect on the process & how do they change behaviors? What evidence to present? Where to build influence? (Convincing your management) How to get started … It’s all easier said than done, of course.

- 2. How we think it’s going to work & how we plan: Process A Process B Process C Process D And then … Late Start: Late Finish or Truncate Project 1 Late StartLate, divergent Project 3 4 5 6 Project 2 (Some) resource // Any resource. e.g. Decisions, environments, priorities, skills, …)

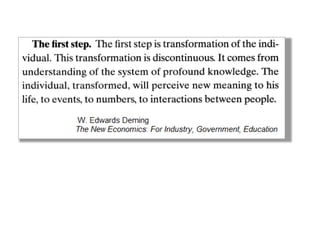

- 4. We are living under the tyranny of the prevailing style of management. Most people imagine that this style of management has always existed and is a fixture. Actually, it is a modern invention, a trap that has led us into decline. Transformation is required. -W. Edwards Deming The New Economics: For Industry, Government, Education

- 6. Business Strategy “economic” view - common currency for measuring value Unmatchable offer ROI Customer Vision Competition Ops/ Staff

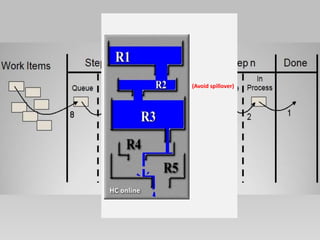

- 8. Team A Team B Component A Component B Team C Team D Team E Team F Initiative 1 X X X X Initiative 2 X X X Initiative 3 X X X X Initiative 4 X Initiative 5 X X Initiative 6 X X Initiative 7 X X X Conflicts Value Stream Analysis

- 10. Value through the system first. (MORE value through the system later)

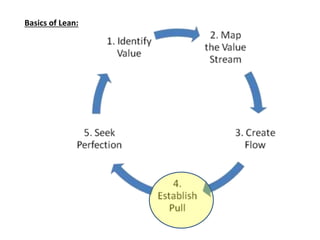

- 11. Basics of Lean:

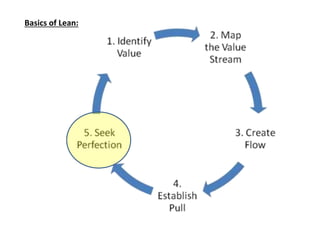

- 13. Basics of Lean:

- 14. What to Measure? • Measure what enables flow and throughput. • Measure value delivered. • Measure how these affect financial results.

- 15. What we’re striving for: Process A Process B Process C Process D Being able to predict when the system will break – overutilization/ interrupted flow. X

- 17. Systems thinking. Engage your right brain…

- 18. 1.Adopt systems thinking. 2.Understand what Value is. 3.Fix Flow. (use data.) 4.Model behavior. YouYourTeam(s)You(again)

- 19. What can I do? 1. Give yourself more credit! 2. Tell the story to as many people as you can. 3. Build a coalition of the willing, enthusiastic, dedicated. 4. Find a champion 5. Keep pushing it. 6. Start fixing important problems • Look for behavior changes. • Set an example.

- 20. More at LEAN.ORG

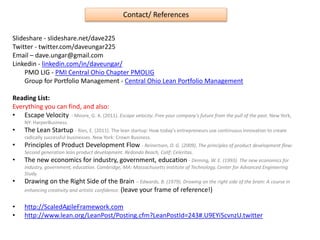

- 21. Contact/ References Slideshare - slideshare.net/dave225 Twitter - twitter.com/daveungar225 Email – dave.ungar@gmail.com Linkedin - linkedin.com/in/daveungar/ PMO LIG - PMI Central Ohio Chapter PMOLIG Group for Portfolio Management - Central Ohio Lean Portfolio Management Reading List: Everything you can find, and also: • Escape Velocity - Moore, G. A. (2011). Escape velocity: Free your company's future from the pull of the past. New York, NY: HarperBusiness. • The Lean Startup - Ries, E. (2011). The lean startup: How today's entrepreneurs use continuous innovation to create radically successful businesses. New York: Crown Business. • Principles of Product Development Flow - Reinertsen, D. G. (2009). The principles of product development flow: Second generation lean product development. Redondo Beach, Calif: Celeritas. • The new economics for industry, government, education - Deming, W. E. (1993). The new economics for industry, government, education. Cambridge, MA: Massachusetts Institute of Technology, Center for Advanced Engineering Study. • Drawing on the Right Side of the Brain – Edwards, B. (1979). Drawing on the right side of the brain: A course in enhancing creativity and artistic confidence. (leave your frame of reference!) • http://ScaledAgileFramework.com • http://www.lean.org/LeanPost/Posting.cfm?LeanPostId=243#.U9EYi5cvnzU.twitter

- 25. Business Strategy why brand identity is important to mode of operation Michael Treacy and Fred Wiersema The Discipline of Market Leaders: Choose Your Customers, Narrow Your Focus, Dominate Your Market

- 26. •Feel Sick •Call to schedule an appointment •Wait on hold •Make appointment •Wait for appointment day to arrive •Check in at office •Wait for nurse to take BP •Wait for doctor •Talk to doctor •Doctor leaves the room •Doctor returns, he’s going to give you a prescription •Wait in lobby to get prescription •Drive to the pharmacy •Fill prescription •Go home •Take pills •Feel better

Editor's Notes

- #3: “Process” can be practices within a sprint or major processes in a linear project. “Project” can be a whole project, a sprint, etc … The processes at the end of the cycle (whatever they are and however big the cycle) start late and get trimmed, due to: Slow decisions (not enough information, no authority) Lack of resources (shifted to other projects, other priorities being added) Too many things to do – time slicing, multitasking Overloading Utilization Planning …. Think of these issues from a TEAM or Project perspective too, and then a portfolio, and an enterprise – not just as an individual. You may be 100% dedicated to an initiative, epic, story, task .. Or your team is .. But if at ANY level resources are overutilized & no room for contingency, the problem caused by delays in the system compounds rapidly, like a shockwave.

- #4: Result – nothing moves very fast. It’s no one’s fault. You want to blame the cars at the front, but the problem is an overutilized system, NOT any individual. (So don’t blame Project #1.) So to speed it up, we eliminate process areas – artificially taking delay out of the system, get things going again. And actually, that’s the right response in a way – but it can’t be to push the bubble down the hose. You have to take the pressure off the system at the source. Fixing a bottleneck at the bottleneck generally doesn’t work – it just moves the bottleneck somewhere else, temporarily.

- #5: Are we clear on the problem? Seen it before? What do we do …? Let’s take a look at Lean. Lean is a system that learns from itself, from its own operation. How do we increase throughput (more value, faster) while maintaining (or increasing) quality? (And how much does quality cost?) ~~? Taking a cue from Deming – view outcomes as a part of the system. So don’t focus on the outcomes – focus on the system that produces the outcomes. Reference: Deming, W. E. (1993). The new economics for industry, government, education. Cambridge, MA: Massachusetts Institute of Technology, Center for Advanced Engineering Study.

- #6: Define what’s valuable – economic view, currency, scoring models Determine how to execute – value stream, resources Establish flow of value through the system – measure cycle time & throughput Limit work-in-progress. Cut waste. Increase capacity by opening bottlenecks. Demand-based, from customer through delivery chain Optimize

- #7: Agilists like to talk about business value. “Do the thing with the highest business value!” But what is business value? Look at Jim Collins/ Hedgehog Concept – it’s not just where the money flows – but where you can create unmatchable power in the marketplace and where you can authentically connect with your customers. That is what sustains your business. The money is what keeps it solvent. (Both in cash flow and in continued investment. No one wants to invest in a business that has no return.) If ROI is what’s really important… why don’t we just sell real estate? Why don’t you become a pro athlete? Because you don’t have an unmatchable offer in that market. ROI is low-level thinking. Yes, a positive return is necessary – but if that’s all you’re thinking about, that’s a sign of organizational immaturity. A company that in it for the long haul is expressing value on how they can keep customers coming back, or how they are changing the world/marketplace. (example – Southwest Airlines does not charge for baggage – that’s sacrificing the customer and abandoning the vision of making air travel as pleasurable as it can be. They don’t trade a short-term ROI for customer loyalty. That’s why they continue to be profitable.) Reference: Collins, J. C. (2001). Good to great: Why some companies make the leap--and others don't. New York, NY: HarperBusiness.

- #9: Where do you have to reallocate, retrain, or not do? This is basic portfolio management – but by highlighting these conflicts, we can look for the optimal tradeoffs.

- #11: First, establish flow. Just getting stories to flow through at a constant rate is the most productive thing you can do. Don’t try to get more through – first get them to flow so you can measure the rate of value through the system. Then, measure. Take that baseline measurement of what flow looks like. Also – don’t focus on a numerical goal – focus them on a means to achieve better results.

- #13: Place value on the things that are closest to the customer. Start at the end of the chain and work backwards on what it takes to give the customers what they need. Spend effort on completing things that are almost ready to move to the next stage – but work right to left, not letting supply outpace demand. (don’t “push” things from one stage to the next – pull them as needed (or just before.)) Key points: 1 – Don’t start anything you can’t finish/ add value to. 2 – Finishing something adds way more value than starting something. 3/c – small stories/epics/projects inherently provide more value than large projects do. (Efficient Frontier - Nobel prize in economics.) References: Collins, J. C., & Hansen, M. T. (2011). Great by choice: Uncertainty, chaos, and luck : why some thrive despite them all. New York, NY: HarperCollins Publishers. Reinertsen, D. G. (2009). The principles of product development flow: Second generation lean product development. Redondo Beach, Calif: Celeritas.

- #15: Adding value –vs sucking value AT OCLC – I switched our measurement from “Are we doing the right things at the right time” to simply “How long does it take us to do anything?” WHY? Because getting work completed and putting value into production was the #1 change I wanted to invoke. So we started measuring success as: once we start on something, do we complete it on schedule? Is it adding value or sucking value? (either by being late or needing extra help.) (Can people game this? You bet – but for the better!) Use metrics to change behaviors, make decisions. Every metric should have a threshold that triggers an action. And rather than measure “are we doing the right things?” I just trust that the prioritization process is good. Because for now, it is. Our problem has never been whether we know the best thing to work on, nor has it been that the teams don’t work fast enough. The problem has always been that we bite off more than we can chew. So that’s what we measure. And people respond to that by making sure they can finish what they start before they start it. Over time, we learn that we can get a truer cycle time measurement if we keep our stories smaller too – not only are they easier to understand & scope, but they all start to be about the same size. Same size initiatives flowing through the system enables us to collect more usable data & greatly helps to keep the system predictable. Tradeoffs: Productivity - vs Responsiveness - Efficient Frontier http://en.wikipedia.org/wiki/Efficient_frontier

- #16: What are the RIGHT things for us to work on? Can we predict when adding another will break the system? That’s the key thing we want to avoid – overloading the system with too many projects/initiatives/stories…

- #17: Plan/ Do/ Study/ Act - to implement, execute, learn and adjust the process.

- #18: QA professionals are natural in this space… knowledge of many, different parts of the system.. Curious.. Embrace ambiguity and make some sense out of it … Understand how the system works … First and foremost – if you think you want to be lean, you have to adopt systems thinking. Put the SYSTEM above objectives, above so-called success. You can’t improve by looking for quick wins and low hanging fruit, or by setting numeric goals. Start to view the enterprise as a system – turning a gear over there creates motion there, there and there.. I guarantee that when you think about this or when you present it to others, people will say “But what about …?” Chances are, whatever that question is – is the WRONG question. They are trying to fit new thinking into an old context. Get yourself out of today’s thinking and the structures you’re comfortable with. The question is not “how do we keep <doing whatever>” but “what is the perfect system for delivering the most value in the shortest amount of time?” (And “What do we mean by ‘value’ ?”) And I stress that to be a systems thinker, you have to engage your right brain. Create visual art, write or read fiction, listen to music with intention, think about things you could invent, think of 100 ways to use a rubber band. You don’t have to produce anything – just get into that mode of thinking, often. And don’t phone it in – drinking wine and painting a copy of a tree is not engaging anything but your social life. References: Owens, D. A. (2012). Creative people must be stopped: Six ways we kill innovation (without even trying). San Francisco: Jossey-Bass. Godin, S. (2012). The Icarus deception: How high will you fly?. New York: Portfolio/Penguin. http://blog.bufferapp.com/connections-in-the-brain-understanding-creativity-and-intelligenceconnections?utm_source=WhatCountsEmail&utm_medium=Above%20the%20Fold&utm_campaign=Above%20the%20Fold&_wcsid=F77673E6099BBF92762F3ABB81240E6E0ED6D63E39980AC5E2E9227FD5C941C0

- #19: #3 – WiP is a liability. Do whatever you can to finish what you start. #2 – sweeping generalization: The most valuable thing is the thing you’ve already started and not yet finished.

- #20: What can I do? Give yourself more credit. Tell the story to as many people as you can. Build a coalition of the willing, enthusiastic, dedicated Find a champion Keep pushing it. Decide whether you want to collect a paycheck or make a difference. (Most people value the latter.) Involve your boss and team as often as you can. Start fixing problems .. (next) Look for behavior changes. (Pit Crew.) Set an example. ** Do you remember – 15, 10, 5 years ago (whenever you became conscious of it) how Agile was the trending topic and your organization was early or late to the party? That’s Lean now – Agile is still there, don’t let that confusion reign – but Lean is the next step, the refinement of agile from a team-level delivery practice to an enterprise value-based strategy & delivery framework. Agile concepts and language still apply – but we’re making it about the total enterprise, sponsored by executives because of the business benefits …

- #21: Understand first, Action plan second While you need to learn big, you can start small. Create an action plan for implementation. Here’s the trick though – you have to understand the big picture. You may not know just how to implement the whole thing, but you have to understand lean as a system so you don’t get caught in the trap of trying to make it jive with an old way of thinking. Lean Action Plan: http://www.lean.org/WhatsLean/GettingStarted.cfm

- #22: A caution on the reading list – like I said at the beginning of this talk – you first need to seek understanding. Create your own philosophy. You can’t find a good cookbook – take ingredients from everywhere, understand how they can work together and cook it yourself. Tomorrow, make something better. This is about learning and changing. (Plan Do Study Act)

- #23: What are YOU taking away from this session? How will you put it into action? What do you need to know more about?

- #25: Fix the biggest problems that 1) cause the most costly delays and/or 2) limit flow/bandwidth/ throughput. Don’t focus on “What you can control” – focus on the biggest, costliest problems with delays & throughput. If it’s out of your control, find an advocate. Create New Habits. Set an example. Don’t make assumptions and don’t manage on intuition. Use experimentation/ testing and data to make decisions. Focus on throughput, not on cost cutting - Fix what limits throughput, not what cuts costs. There is a limit to how much cost-cutting you can do – and eventually, your mode of operation is to contract/shrink. (Cost-cutting may be beneficial if costs are way out of line.) More value through the system, faster. Not the same value through the system, cheaper. Focus on flow before focusing on bottlenecks. Don’t fix “low hanging fruit” problems. These are a distraction. You’re missing 80% of the tree. Fix the biggest problems that 1) cause the most costly delays and/or 2) limit flow/bandwidth. (Yes, I said fix problems with costly. But I mean delays – limits to throughput – fix the delays that cost the most in terms of throughput.) **Delay is THE single most important thing to fix. (reinertsen) Reference: Reinertsen, D. G. (2009). The principles of product development flow: Second generation lean product development. Redondo Beach, Calif: Celeritas.

- #26: Key Point: If you are creating a new system of management, a new methodology – What is its aim? More value through the system, but in what respect? (ie brand) Who are we? When we talk about portfolio strategy, prioritization and project selection, we need a standard for making those decisions. Brand is your customers’ perceptions of you. (Including potential customers.) Uber – is not a product leader just because they were innovative. They are not customer-intimate just because they serve their customers well. They are operationally excellent because they can get a car to you when you need one. (See also, maybe, for other reasons – the Lean Canvas) Reference: Treacy, M., & Wiersema, F. D. (1995). The discipline of market leaders: Choose your customers, narrow your focus, dominate your market. Reading, Mass: Addison-Wesley Pub. Co. Ries, E. (2011). The lean startup: How today's entrepreneurs use continuous innovation to create radically successful businesses. New York: Crown Business. https://www.linkedin.com/pulse/article/20141020200319-110300724-it-s-your-operating-model-focus-on-it?trk=mp-edit-rr-posts

- #27: (Is there some way we can PULL the patient’s needs?) Between the time you recognize the need to visit and the time you have a cure, how much time do you waste? (list) Which of these steps actually add value? What is the elapsed time/ cycle time? What if there were a system where you describe your symptoms and get a remedy within minutes? How great would that be? Think of all the waste we could cut out of this system. Now think about your own operations. How much time do you spend waiting for no reason, letting WIP sit idle? Where can you cut waste? This is called Value Chain analysis. *If the doctor only saw one patient at a time, would that mean less waiting? What if the doctor saw two patients at a time? From the previous slide, we know what flow looks like and we can measure the rate of value through the system. So now do we get more value through when we have one patient at a time or two? Let’s test it. Let’s measure. (I should add that you can create mathematical models that can take the place of much testing – although you still need to test once you’ve created a model that appears to increase efficiency.) *If we built a self-diagnosis machine, would that speed up delivery? What about quality? What changes can we make that will do the most to eliminate delays in value delivery? (And does it affect quality?) All good areas of study and important to understanding lean, Kanban, flow. Reference: https://www.coursera.org/course/operations https://www.udemy.com/operations-management

- #28: Demand management Estimate on ideal team weeks, not on fte. Use Average Cycle Time to estimate. A pit crew takes lots of individual skills – but the race is won by the team. Imagine if the car’s owner tried to allocate crew members based on how long their job took in the pit. The pit crew knows that their job is to work together to get the pit time as low as possible – let them figure it out. Give them the metric – average time in/out – 8 seconds…. Read More: http://www.rallydev.com/community/business-agility-0

- #29: Make your biggest constraints internal, so you can change them at will. Eg *Rate of growth in a market segment * supply (capacity) and demand * Demand – via marketing strategy, don’t create more demand for your product than you can supply. Capacity limits Capacity limits – do not plan utilization at 100% Much easier to control these and adjust them as your throughput rises (or falls.) It would be harder to satisfy demand if you’re always at capacity or always way overstaffed (waste)

- #30: Segment resources – split into finite/defined budget areas 1) the production of new opportunities –vs- 2) small enhancements and 3)production support. These three areas operate in different modes – support has a much faster turnaround time than new opportunities do. It’s difficult to establish flow when the process areas are not consistent in their mode of operation. (ie If you combine user stories/ epics with production support, it’s much more difficult to measure how long it takes to turn around things that enter the system – because they are not the same size & get completed at different rates.) BUT – that’s a theory. (Geoffrey Moore, Don Reinertsen, et al.) Use data to test this for yourself.