Ich guidelines for stability studies 2

- 1. PRESENTED BY: O.PRIYANKA M-PHARM DEPARTMENT OF PHARMACEUTICS

- 3. Drug Stability refers to the capacity of a drug substance or product to remain within established specifications of identity, strength, quality, and purity in a specified period of time. Stability is officially defined as the time lapse during which the drug product retains the same properties and characteristics that it possessed at the time of manufacture. The stability of a product is expressed as the expiry period or technically as shelf life.

- 4. STAGE 1-Early stage stress-and accelerated testing with drug substances STAGE 2-Stability on pre-formulation batches STAGE 3-Stress testing on scale-up batches STAGE 4-Accelerated and long term testing for registration purposes STAGE 5-On-going Stability Testing STAGE 6-Follow-up Stabilities

- 5. To gather information during preformulation stage to produce a stable product. To determine maximum expiration date. To get an idea of storage condition. To determine the packaging components. To establish retest period of pharmaceuticals. To establish Transport conditions.

- 6. Chemical degradation of active drug may reduce the quality of therapeutic indices like 5- flurouracil, carbamazepine etc have very small therapeutic range, slight degradation of drug may produce sub therapeutic concentration. After degradation a drug may produce more toxic product(s) which may be more toxic than the parent product. Instability of drug product reduce bioavailability. This may be caused by physical or chemical instability. Instability of a product may change the physical appearance of the product.

- 7. DRUG AND EXCIPIENT: - Physical form -particle size -surface area FORMULATION: -drug excipient ratio -Processing method -pH -solvent -chelating agent ENVIRONMENT: -Temperature -Relative humidity -Packaging -Light -oxygen

- 8. Chemical : Each active ingredient retains its chemical integrity and labeled potency within the specified limit Physical : The original Physical properties including appearance, palatability, uniformity, dissolution and suspendability are retained . Microbiological : Sterility or resistance to microbial growth is retained according to specified requirement . Therapeutic : Therapeutic effect remains unchanged Toxicological : No significant increase in toxicity occurs

- 9. Accelerated stability testing Long term testing Stress testing Photo stability study

- 11. The ICH (International Conference on Harmonization) Guidelines Q1A(R2) “Stability testing of new drug substances and products” is the “gold standard” for conducting stability studies. This is valid for “new drug substances or drug products” that are sufficient for a registration application.

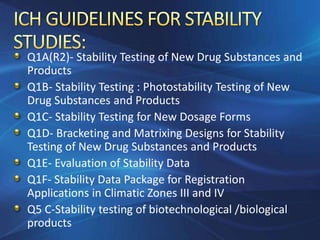

- 13. Q1A(R2)- Stability Testing of New Drug Substances and Products Q1B- Stability Testing : Photostability Testing of New Drug Substances and Products Q1C- Stability Testing for New Dosage Forms Q1D- Bracketing and Matrixing Designs for Stability Testing of New Drug Substances and Products Q1E- Evaluation of Stability Data Q1F- Stability Data Package for Registration Applications in Climatic Zones III and IV Q5 C-Stability testing of biotechnological /biological products

- 14. OBJECTIVE OF THE GUIDELINE: It defines stability of drug substance and drug product for registration of application of NCE or associated drug, within three regions of ICH i.e; EU, Japan, USA . NOTE: It does not cover testing for registration of drug substance or product intended for import or export to other areas of the world.

- 15. 1. Purpose of stability testing is to provide evidence how quality varies with time under influence of - temperature - humidity - light 2. establish re-test period for drug substances RETEST PERIOD: the period after which samples of the drug substance should be examined to ensure that the material is still in compliance with the specification, and thus suitable for use in manufacturing. A retest period should be proposed on the basis of stability results and may be extended to five years (e.g., Ethambutol 2HCl, or Isoniazid) 3. establish shelf life for drug products SHELF LIFE: (EXPIRY DATE/EXPIRATION DATING PERIOD) The period of time during which a pharmaceutical product, if stored correctly, is expected to comply with the specification as determined by stability studies on a number of batches of the product. The shelf-life is used to establish the expiry date of DRUG PRODUCT.

- 16. 4. recommends storage conditions 5.Gives Test conditions based on analysis of effects of climatic conditions in the three regions of the EU, Japan, USA. 6. Gives mean kinetic temperature which is derived from climatic data 7.divided world into four climatic zone I-IV - This guideline addresses climatic zones I and II 8. And the Stability information generated in one of the three regions is mutually acceptable to the other two provided: - information is consistent with this guideline, - labelling is in accord with national/ regional requirements.

- 17. CLIMATIC ZONE DEFINITION STORAGE CONDITIONS TEMPERATE CLIMATE 210C/45 % R.H I SUBTROPICAL AND 250C/60 % R.H II MEDITERRANEAN CLIMATE HOT , DRY CLIMATE 300C/35 % R.H III HOT , HUMID CLIMATE 300C / 70% R.H IV

- 18. Stress Testing These guidelines help to Q1 A (R2)guidelines identify the likely degradation products , to Stress testing establish the degradation pathway and intrinsic stability of the molecule. Selection of batches Container closure system specifications Testing frequency Selection of batches At least 3 primary Storage condition batches of the drug substance should be selected. The quality should be Stability commitment representative to quality of material used evaluation for production scale. Statements/labelling

- 19. Container Closure system: Should simulate packaging proposed for Q1 A (R2)guidelines storage and distribution. Stress testing Selection of batches Specification: Container closure specification: system • list of tests, Specifications • reference to analytical procedure, • proposed acceptance criteria Testing frequency Storage condition Test Attributes • attributes that are susceptible to changed Stability commitment storage, evaluation • influence quality, safety and/or efficacy Statements/labelling • Should cover physical, chemical, biological and microbiological attributes

- 20. TESTING FREQUENCY: TestingfrequencyFor productswitha proposed shelflifeof at least 12 months: Q1 A (R2)guidelines First year------------------3 month Stress testing Second --------------------6 month Selection of batches Thereafter------------------annually Container closure through out the proposed re-test system period specifications At accelerated storage condition Testing frequency minimum of three time points (0, 3 and 6 months), from a 6- month study. Storage condition Stability commitment At Intermediate storage condition minimum of four time points (0, 6, 9 and 12 months), from a 12- evaluation month study. Statements/labelling

- 21. STORAGE CONDITIONS: Long term testing should cover a minimum of 12 months duration on at least three primary batches at time of submission and should Q1 A (R2)guidelines be continued sufficient to cover the proposed re-test period. Stress testing GENERAL: Selection of batches STUDY STORAGE CONDITION DURATION Container closure system Long term* 25°C ± 2°C/60% ± 12 months 5% specifications or 30°C ± 2°C/65% ± Testing frequency 5% Storage conditions Intermediate** 30°C ± 2°C/65% ± 6 months 5% Stability commitment Accelerated 40°C ± 2°C/75% ± 6 months evaluation 5% Statements/labelling

- 22. STUDY STORAGE DURATION CONDITION Long term* 25°C ± 2°C/ 40% RH ± 5% 12 months or 30°C ± 2°C/ 35% RH ± 5% Intermediate** 30°C ± 2°C/65%RH ± 5% 6 months Accelerated 40°C ± 2°C/75%RH ± 5% 6 months

- 23. STUDY STORAGE CONDITION DURATION Long term 5°C ± 3°C 12 months Accelerated 25°C ± 2°C/60% ± 5% 6 months If significant change between 3 and 6 months at accelerated testing propose re-test data based on real time data. (LONG TERM STUDY) If significant change within 3 months discussion should address excursions outside label storage. Single batch shorter than 3 months with more frequent testing.

- 24. STUDY STORAGE DURATION CONDITIONS Long term - 20 °C ± 5°C 12 months Re-test period based on real time data at long term storage condition. In absence of accelerated storage condition testing on a single batch at an elevated temperature e.g. 5°C ± 3°C address short term excursions

- 25. Stability Commitment: When Re-test period not covered or not mentioned Q1 A (R2)guidelines long term stability data do not cover proposed re-test period granted at Stress testing time of approval, commitment should be made to continue post approval to establish re-test period Selection of batches Container closure Not required for Submission which includes data from 3 production system batches, commitment to continue through proposed re-test period. specifications Fewer than three production batches commitment continue with Testing frequency these studies through proposed re-test period and place additional production batches to a total of three on long term stability through Storage condition proposed re-test period Stability commitment No Production batches commitment to place first three production batches on long term stability studies through proposed re-test period. evaluation Statements/labelling

- 26. A systematic approach should be adopted in the presentation and evaluation of the stability information which covers the physical,chemical & biological parameter. A minimum of 3 batches of drug product was tested. The analyst must found the batch to batch variability & if it is small than only it is accepted & it can be done by different statistical test's ( P value for level of significance for rejection). Where the data shows so little degradation & so little variability that is apparent from looking the data that the requested shelf life will be granted. & it is normally unnecessary to go through the formal statistical analysis. Any evaluation also consider the not only the assay but also consider the other parameter testing & also the different stability and degradation performance. The stability of the drug product after reconstitution or diluting according to labeling ,should be addressed to provide appropriate and supportive information.

- 27. A 5% change in assay from its initial value. Any degradation product exceeding its acceptance criterion. Failure to meet the acceptance criteria for appearance, physical attributes, and functionality test (e.g., colour, phase separation, hardness). As appropriate for the dosage form, e.g., failure to meet the acceptance criteria for dissolution for 12 dosage units.

- 28. STATEMENTS /LABELLING: Q1 A (R2)guidelines Stress testing A storage statement should be Selection of batches established based on the stability Container closure evaluation of the drug substance. system specifications Terms such as “ambient conditions” or Testing frequency “room temperature” should be avoided. Storage condition Stability commitment Retest date should be displayed on the container label if appropriate. evaluation Statements /labelling

- 29. Light can affect drugs, causing chemical changes so… To Evaluate that light exposure does not result in unacceptable change. Provides means of screening drug early in the development process & allows identification of particular photo labile drug. gives idea about how to store drug For generation of photo stability information for submission in Registration Applications for new molecular entities and associated drug products.

- 30. A systematic approach to photostability testing is recommended covering, as appropriate, studies such as : i) Tests on the active substance; ii) Tests on the exposed product outside of the immediate pack, and if necessary ; iii) Tests on the product in the immediate pack; and if necessary ; iv) Tests on the product in the marketing pack.

- 31. Combination of visible and UV light. D65/ID65 emission standard such as an artificial daylight fluorescent lamp combining visible and ultraviolet (UV) outputs, xenon, or metal halide lamp. D65 is the internationally recognised standard for outdoor daylight as defined in ISO 10977 (1993). ID65 is the equivalent indoor indirect daylight standard. For a light source emitting significant radiation below 320 nm, an appropriate filter(s) may be fitted to eliminate such radiation.

- 32. Samples should be exposed to light providing an overall illumination of not less than 1.2 million lux hours and an integrated near ultraviolet energy of not less than 200 watt hours/square meter. Protected samples (e.g., wrapped in aluminum foil) are used as dark controls to evaluate the contribution of thermally induced change to the total observed change [ LUX = Is the unit which indicates the intensity or the brightness of the light]

- 33. definition: A new dosage form is defined as a medicinal product which is a different pharmaceutical product type, but containing the same active substance as included in an existing product approved by the pertinent regulatory authority. Include: products of a different route of administration (e.g., oral to parenteral), new specific functionality/delivery systems (e.g., immediate release tablet to modified release tablet) and different dosage forms of the same route of administration (e.g., capsule to tablet, solution to suspension). Stability protocols for new dosage forms should follow the guidance in the parent stability guideline in principle. However, a reduced stability database at submission time may be acceptable with proper justification. e.g., 6 months accelerated and 6 months long term data from ongoing studies may be acceptable in certain justified cases.

- 34. Tablets – Appearance, colour, odour, assay, disintegration/dissol ution, moisture and friability or hardness testing. Hard gelatin capsules - Appearance, colour, odour of contents, assay, disintegration/dissolution, moisture and microbial limits Soft gelatin capsules - Appearance, colour, odour of contents, assay, disintegration/dissolution, moisture, m icrobial limits, ph , leakage and pellicle formation. Emulsions – Appearance including phase separation, colour, odour, assay, pH, viscosity, preserva tive content, weight loss and microbial limits.

- 35. Suppositories – Appearance, colour, assay, particle size, softening range, appearance, dissolution and microbial limits. Small volume parenteral: Drug injection – Appearance, colour, assay, ph, preservative, content, particulate matter, sterility and pyrogenicity. Large volume parenteral - Appearance, colour, assay, ph, preservative content, particulate matter, sterility and pyrogenicity Transdermals – Appearance, assay, leakage, microbial limit/sterility, peel and adhesive forces, drug release rate.

- 36. Outlines recommendations, principles, and considerations for reduced designs. Terms: Full Study Design: samples for every combination of all design factors are tested at all time points Reduced Study Design: not all samples for every factor combination are tested at all time points ex: bracketing, matrixing.

- 37. Applicability of Reduced Designs Applicable to formal stability studies of most types of drug products Drug substances: matrixing limited, bracketing generally not applicable Whether bracketing or matrixing depends on circumstances Any reduced design should be justified. Type and level of justification depends on avaiable supporting data. Careful consideration and scientific justification, if bracketing and matrixing in one design.

- 38. Bracketing is the design of a stability schedule such that only the extremes of certain design factors are tested at all time points. - different strengths - different container size and/or fill Stability of intermediate levels represented by stability or tested extremes. Bracketing design not appropriate, if tested samples are not the extremes.

- 39. BRACKETING - Strengths: Applicable: strengths of identical or closely related formulations Applicable with additional justification (e.g., supporting data): strengths where the relative amounts of the drug substance and excipients vary within the product line Not applicable: different excipients among strengths Bracketing – Container Size, Fill: Applicable: same container closure system where either the container size or fill varies while the other remains constant Applicable with additional justification (e.g., supporting data): same container closure system but both the container size and fill vary Not applicable: different container closure systems

- 40. Three strengths and three container sizes: Container size Dosage strength 50 mg 75 mg 100mg 1 2 3 1 2 3 1 2 3 15 ml T T T T T T 100 ml 500 ml T T T T T T

- 41. MATRIXING: Def: testing a selected subset of the total number of possible samples for all factor combinations at a specified time point, while testing another subset of samples at a subsequent time point applicable: strengths with identical or closely related formulations container sizes or fills of the same C/C system different batches made with the same equipment and process applicable with additional justification: where the relative amounts of excipients change or different excipients are used not applicable: different storage conditions different test attributes

- 42. Design should be balanced as far as possible so that each combination is tested to the same extent over the intended duration of the study and through the last time point prior to submission Where time points are matrixed, all selected factor combinations should be tested at the initial and final time points (and the last time point prior to submission)

- 43. Type Storage period in months(time points) Total number 0 3 6 9 12 18 24 36 48 60 A × × - - × - - × - × 5 B × - × - × × - - × × 6 C × - - × × - × - - × 5

- 44. It describes: How to propose a retest period for drug substances and a shelf life for drug products in the registration application When and how a extrapolation beyond available data can be considered. EXTRAPOLATION:extrapolation is the practice of using a known data set to infer the information about a future data.

- 45. CASE 1: NO SIGNIFICANT CHANGE AT ACCELERATED CONDITION: Long term and accelerated Long term/accelerated data data showing a little or no showing change over change over time and time/variability little /no variability Drug substance/product will remain within the Stability analysis of long term data can acceptance criteria during the proposed retest be useful attribute to establish retest period/shelf life period Statistical analysis is not required

- 46. CASE 2: SIGNIFICANT CHANGE AT ACCELERATED CONDITION: No significant change at intermediate Significant change at intermediate The extent of extrapolation wpould depend on whether LT data for attributes are amenable to The proposed retest period or shelf statistical analysis life should not exceed the period covered by long term data Data not amenable to data amenable to statistical analysis statistical analysis The proposed retest The proposed retest period or period/shelf life can be shelf life can be upto one &half upto 3 months beyond the times but should not be more than period covered by LT data 6 months beyond the period covered by LT data

- 47. REGRESSION ANALYSIS: appropriate approach for evaluation of stability data Upper and lower confidence limit(95%) should be calculated and compared to acceptance criterion APPENDICES: APPENDIX –A:decision tree for data evaluation for retest period or shelf life estimation of drug substance and drug product APPENDIX –B:examples of statistical approaches to stability data analysis.

- 48. Q1F- Stability Data Package for Registration Applications in Climatic Zones III and IV Climatic conditions in the countries where the product is to be marketed should be carefully considered during the development phase . So the world has been divided into four climatic zones based on the prevalent annual climatic conditions. Temperature and humidity determine the storage conditions and so they greatly affect the stability of the product.

- 49. Tests at elevated temperatures and/or extremes of humidity Special transportation and climatic conditions outside the storage conditions recommended in this guideline should be supported by the additional data. Stability testing at a high humidity condition, e.g. 25°C/80%RH, is recommended for solid dosage forms in water- vapour permeable packaging viz., tablets in PVC/ aluminium blisters, intended to be marketed in territories with extremely high humidity conditions in Zone IV.

- 50. www.ich.org/products/guidelines/quality.html www.ema.europa.eu/pdfs/human/ich/273699e n.pdf www.ich.org/fileadmin/.../ICH.../Guidelines/.../ Q1B_Guideline.pdf apps.who.int/prequal/trainingresources/pq.../st abilitystudies.ppt Jens T cartensen, C.T Rhodes Drug stability Principles and Practices, Third Edition

Editor's Notes

- #46: Stability analysis of long term data can be useful attribute to establish retest period

![Samples should be exposed to light providing an

overall illumination of not less than 1.2 million

lux hours and an integrated near ultraviolet

energy of not less than 200 watt hours/square

meter.

Protected samples (e.g., wrapped in aluminum

foil) are used as dark controls to evaluate the

contribution of thermally induced change to the

total observed change

[ LUX = Is the unit which indicates the intensity

or the brightness of the light]](https://image.slidesharecdn.com/ichguidelinesforstabilitystudies2-120728080032-phpapp02/85/Ich-guidelines-for-stability-studies-2-32-320.jpg)