implementation_of_a_risk-based_process_safety_management_system_framework.pptx

- 1. Implementation of a Risk-Based Process Safety Management System A Resource for AGA Members AGA Process Safety Sub-Committee Process Safety Framework Initiative December, 2016 CCPS, Guidelines for Risk-Based Process Safety Copyright © 2007 AIChE and used with permission PSM implementation at PG&E and used with permission

- 2. Notice In issuing and making this publication available, AGA is not undertaking to render professional or other services for or on behalf of any person or entity. Nor is AGA undertaking to perform any duty owed by any person or entity to someone else. Anyone using this document should rely on his or her own independent judgment or, as appropriate, seek the advice of a competent professional in determining the exercise of reasonable care in any given circumstances. The statements in this publication are for general information and represent an unaudited compilation of statistical information that could contain coding or processing errors. AGA makes no warranties, express or implied, nor representations about the accuracy of the information in the publication or its appropriateness for any given purpose or situation. This publication shall not be construed as including, advice, guidance, or recommendations to take, or not to take, any actions or decisions in relation to any matter. Should you take any such action or decision; you do so at your own risk. Information on the topics covered by this publication may be available from other sources, which the user may wish to consult for additional views or information not covered by this publication. Copyright © 2016 American Gas Association. All rights reserved. www.aga.org

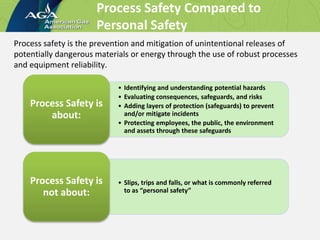

- 3. Process Safety Compared to Personal Safety Process safety is the prevention and mitigation of unintentional releases of potentially dangerous materials or energy through the use of robust processes and equipment reliability. • Identifying and understanding potential hazards • Evaluating consequences, safeguards, and risks • Adding layers of protection (safeguards) to prevent and/or mitigate incidents • Protecting employees, the public, the environment and assets through these safeguards Process Safety is about: • Slips, trips and falls, or what is commonly referred to as “personal safety” Process Safety is not about:

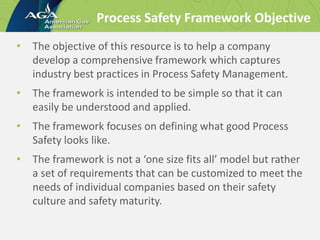

- 4. Process Safety Framework Objective • The objective of this resource is to help a company develop a comprehensive framework which captures industry best practices in Process Safety Management. • The framework is intended to be simple so that it can easily be understood and applied. • The framework focuses on defining what good Process Safety looks like. • The framework is not a ‘one size fits all’ model but rather a set of requirements that can be customized to meet the needs of individual companies based on their safety culture and safety maturity.

- 5. Various Safety Management Systems • OSHA Process Safety Management (PSM) 29 CFR 1910.119 (published in 1992; 14 elements) • EPA Risk Management Plan (RMP) (per the Clean Air Act; 16 elements) • American Chemistry Council (ACC) Responsible Care (18 elements) • CCPS Risk-Based Process Safety (RBPS) (introduced in 2007; 20 elements) – the most comprehensive and rigorous system • API Recommended Practice 1173 Pipeline Safety Management System (API 1173) (introduced in 2015; 11 elements)

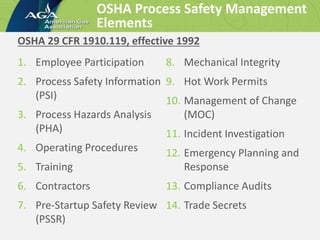

- 6. 1. Employee Participation 2. Process Safety Information (PSI) 3. Process Hazards Analysis (PHA) 4. Operating Procedures 5. Training 6. Contractors 7. Pre-Startup Safety Review (PSSR) 8. Mechanical Integrity 9. Hot Work Permits 10. Management of Change (MOC) 11. Incident Investigation 12. Emergency Planning and Response 13. Compliance Audits 14. Trade Secrets OSHA 29 CFR 1910.119, effective 1992 OSHA Process Safety Management Elements

- 7. CCPS Risk-Based Process Safety Elements PG&E representation of the 20 elements of Risk Based Process Safety from CCPS “Guidelines for Risk-Based Process Safety “, 2007, AIChE, NY

- 8. 1. Leadership & Management Commitment 2. Stakeholder Engagement 3. Risk Management 4. Operational Controls 5. Management of Change (MOC) 6. Incident Investigation 7. Safety Assurance 8. Emergency Preparedness and Response 9. Competence, Awareness and Training 10. Documentation and Record Keeping 11. Management Review and Continuous Improvement API RP 1173 Pipeline Safety Management System Elements

- 9. • Gas Transmission Pipelines • Gas Distribution Services and Distribution Mains • Regulator Stations • Compressor Stations • Gas Terminals • Gas Storage Facilities • LNG/CNG Facilities • Measurement and Control • Customer Connected Equipment Apply Process Safety Management to These Assets

- 10. Where to Start? Ultimate Goal - reduce risk to a level that can be tolerated by all concerned • Multiple Frameworks to select from • Honing in on RBPS • Why RBPS? • What is RBPS?

- 11. • Reduce risk associated with incidents involving uncontrolled releases of hazardous material and energy. • Improve efficiency by consolidating a range of discrete safety-related activities to protect employees, the public, the environment and property. • Cost savings by identifying safety enhancements early in the design process. • Reduced downtime and maintenance cost. • Improved operations, customer satisfaction, reputation, employee relations, recruitment and retention. Reasons to Implement an RBPS Management System

- 12. • Incorporates state-of-the-art and experience-tested features in a holistic process safety management system. Includes novel elements such as culture, outreach, conduct of operations, metrics and management review addressing gaps in process safety management widely observed over 15 years. • Holistic application will tend to minimize aggregate risk. Intensity of work activities for each element will be better tuned to the residual risk they are designed to manage. • Optimizes the use of resources. Description of each element includes lists of several ideas for improving effectiveness either through efficiency improvements (make do with less) or performance improvements (maximize benefits from existing efforts). • Provides a management system that is better tuned to hazards and risks. Help decide whether the level of effort applied to work activities for each element is inadequate, excessive, or optimal. Scope of the work activities at a required level of reliability helps focusing the effort and promote risk management practices. Attributes of an RBPS Management System

- 13. To be implemented at a risk-appropriate level of rigor. 1. Commit to process safety — the cornerstone of process safety excellence 2. Understand hazards and evaluate risks — the foundation of a risk-based approach 3. Manage risk — the ongoing execution of RBPS tasks 4. Learn from experience — the opportunities for improvement RBPS: Four Accident Prevention Pillars

- 14. • The RBPS approach recognizes that all hazards and risks are not equal. • It focuses more resources on greater hazards and higher risks. • It puts just enough energy into each activity to meet the anticipated needs for that activity. • Limited company resources can be optimally apportioned to improve both facility safety performance and overall business performance. The RBPS Approach

- 15. • Obtain management commitment and support. • Solicit assistance. • Ensure adequate resource allocation. • Define scope and objectives. • Define roles and responsibilities. • Manage expectations. • Communicate. • Advance in discrete, manageable and well defined steps. • Keep it simple. • Obtain widespread commitment. • Provide adequate training. • Field-test the system prior to official implementation. • Develop tools to streamline future implementation activities. • Apply proven project management tools and methods. • Be flexible and be aware. • Continually reinforce the commitment. First Steps - Implementation of an RBPS Management System

- 16. Three RBPS criteria should be considered for improving a PSM system: 1. Understanding of the hazards and risks of the facilities and operations. 2. Understanding of the demand for (and resources used in) process safety activities. 3. Understanding of how process safety activities are influenced by the process safety culture within the organization. Select RBPS Elements that Provide Greatest Risk Benefit to the Facility

- 17. CCPS, Guidelines for Risk-Based Process Safety Copyright © 2007 AIChE and used with permission Select RBPS Elements that Provide Greatest Risk Benefit to the Facility (continued)

- 18. • Develop and deploy a strategy to implement a process safety management system. • Determine current state by performing a self assessment or benchmarking study for elements of interest. If you are unable to include all 20 RBPS elements, consider including the 10 listed on slide 22 in combination with the self assessment tool described in slides 20 and 21. • Develop multi-year roadmaps to close gaps and achieve desired level of process safety maturity. Track progress on maturity curves. • Develop and deploy a Process Safety Communication Plan. • Establish interdependencies and integration of process safety management with other initiatives underway and add process safety rigor. • Establish leading and lagging metrics relevant to the organization or to the current maturity level. Over time more metrics can be evaluated. • Consider implementing a management review and continuous improvement process. • Review implementation effectiveness. Successful Deployment of an RBPS Management System

- 19. KeyPrinciples andessential Features - UpgradingOperatingprocedures. KeyPrinciples andessential Features - UpgradingConductof Operations KeyPrinciples andessential Features - UpgradingMoC Element. MaintainaDependable Practice: - Establish ManagementControls - Control Procedure Formatand Content - Control documents. IdentifywhatOperationProcedures are needed: - ConductaTask Analysis - Determine the level of detail. - Address all OperatingModes. DevelopProcedures: - Address Operatinglimits - Address consequences of deviation - steps to avoid orcorrectdeviations - clearconcise instructions - follow the logicof the process DevelopMetrics. MaintainaDependable Practice: - Define roles and responsabilities -Establish standards forperformance - Validate programeffectiveness Control Operations Activities: - Follow written procedures - Follow safe work practices - Use qualified workers - Assign adequate resources - Formalize communications, etc. Control the status of Systems and Equipment: - Formalize equipment/assetownership - MonitorEquipmentstatus - Maintain good housekeeping - Maintain Labeling - Maintain Instruments and tools. DevelopMetrics. MaintainaDependable Practice: - Establish ConsistentImplementation - Involve CompetentPersonnel - Keep MoCpractices effective. IdentifyPotential Change Situations: - Define the scope of the MoCsystem - Manage all sources of change Evaluate possible impacts: - Provide appripriate inputinfo to manage the change - Apply appropriate technical rigorforthe MoCreview process - Ensure thatMoCreviewers have appropriate expertise and tools Decide whethertoallowthe change: - Authorize changes. - Ensure thatchange authorizers address importantissues. Complete follow-upactivities: - Update records - Communicate changes to personnel - Enactrisk control measures - Maintain MoCrecords. DevelopMetrics. RBPS Implementation Examples RBPS Systems Implementation Examples CCPS, Guidelines for Risk-Based Process Safety Copyright © 2007 AIChE and used with permission Ex 1: Upgrading Operating Procedures Ex 2: Upgrading Conduct of Operations Ex 3: Upgrading MoC Element Key Principles and essential Features -

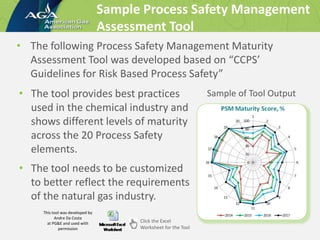

- 20. Sample Process Safety Management Assessment Tool • The following Process Safety Management Maturity Assessment Tool was developed based on “CCPS’ Guidelines for Risk Based Process Safety” • The tool provides best practices used in the chemical industry and shows different levels of maturity across the 20 Process Safety elements. • The tool needs to be customized to better reflect the requirements of the natural gas industry. Click the Excel Worksheet for the Tool Sample of Tool Output This tool was developed by Andre Da Costa at PG&E and used with permission

- 21. Process Safety Management Assessment Tool Guide (continued) • Review the 20 Risk Based Process Safety elements and select elements of immediate interest to your organization; delete the tabs of elements that you do not intend to assess. CCPS determined that at least 6 of the elements are critical to success: Process Safety Culture, Compliance with Standards, PHA, Management of Change, Asset Integrity and Reliability and Metrics. • Review the practices for selected elements of interest. Delete any practices that may not apply to your organization. Change the language/terminology of any practices that would not be readily understood by your organization, use terms that your organization can relate to. • Establish a multi-year timeframe to track progress to desired maturity. • Revise scoring system if required (e.g. adding weights to practices). Simple scores used without weights in the attachment. • Get relevant teams to complete the assessment in facilitated sessions. The facilitator must understand the tool and the language of the best practices. • Track assessment results on radar charts. • The benefit of self assessment is not the actual percentage scores, but rather the relative scores (low, intermediate or high level of maturity) and identification of gaps to work on.

- 22. Baseline PSM Elements Selected top 10 common Process Safety Management elements as a starting point. 1. Process Safety Culture 2. Compliance with Standards 3. Process Knowledge Management (PSI) 4. Hazard Identification and Risk Analysis (PHA) 5. Safe Work Practices 6. Asset Integrity and Reliability 7. Management of Change (MOC) 8. Operational Readiness (PSSR) 9. Incident Investigation 10.Measurement and Metrics Elements

Editor's Notes

- #6: There are various safety management systems available. Listed on this slide are the more commonly known ones in our industry in the order of release. In the following slides, we will focus on elements in the OSHA PSM, the CCPS RBPS, and the API RP 1173. OSHA PSM is the primary safety management system in use for addressing unintentional hazards and energy releases RBPS is the most comprehensive and rigorous API RP 1173 pertains specifically to pipeline operations

- #11: The goal of process safety management is to consistently reduce risk to a level that can be tolerated by all concerned—by facility staff, company management, surrounding communities, the public at large, and industry and government agencies. Given the CCPS RBPS is the most comprehensive and rigorous Process Safety Management framework, we will do a deep-dive into understanding and applying RBPS. Reasons to implement RBPS will be covered in the following slides as well as what RBPS is and examples of its application.

- #14: A work force that is convinced the organization fully supports safety as a core value will tend to do the right things, in the right ways, at the right times — even when no one is looking. An organization can use this information to allocate limited resources in the most effective manner. Organizations must 1)Operate and maintain processes that pose the risk, 2) Keep changes to those processes within risk tolerances and 3) Prepare for, respond to, and manage incidents that do occur. Provide direct feedback on the workings of RBPS systems. When an element’s performance is unacceptable, organizations must use their mistakes — and those of others — as motivation for action.

- #15: A systematic, risk-based approach to safety design can help eliminate hazards that pose intolerable risk from the process and mitigate the potential consequences of hazards. Risk-based approaches to decision-making have gradually gained ground in process safety. Risk-based approaches can benefit process safety environmental mangers by supporting a clear, consistent approach to decision- making about risks and by providing about safety design choices that key stakeholders. can understand.

- #16: Completely revamp the management system for one or more elements Efforts to implement Process Safety management system will be less effective if the accompanying culture element does not embrace the pursuit of excellence.

- #17: If not ready to embark on a large initiative right now = focus on incremental improvement.

- #18: Start with the RBPS elements that provide the greatest risk benefit to the facility….one piece at a time. Moving too quickly would be a mistake, rapid change can be confusing, even mind-numbing. There is no mandate to implement all 20 elements. Despite efforts to reduce risk with inherently safer approaches, managing risk will remain critical to the success of any facility that stores or process hazardous chemicals.

- #20: This slide provides three examples of how the RBPS may be implemented.

- #23: Overwhelmed? The AGA PSM subcommittee identified 10 elements out of the 20 that comprise the RBPS for natural gas operators to consider as a baseline or starting point for establishing a foundation for an effective process safety management system. These 10 elements stemmed from six identified by the CCPS as absolutely valuable, plus four others identified by the subcommittee as equally needed to advance PSM within a company.