kupdf.net_shortcircuit-iec as per ir.pdf

- 1. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Short-Circuit Analysis IEC Standard

- 2. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 2 CORTO CIRCUITO Estándar de ANSI/IEEE & IEC. Análisis de fallas transitorias (IEC 61363). Efecto de Arco (NFPA 70E- 2000) Integrado con coordinación de dispositivos de protección. Evaluación automática de dispositivos. Características principales:

- 3. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 3 Purpose of Short-Circuit Studies • A Short-Circuit Study can be used to determine any or all of the following: – Verify protective device close and latch capability – Verify protective device interrupting capability – Protect equipment from large mechanical forces (maximum fault kA) – I2 t protection for equipment (thermal stress) – Selecting ratings or settings for relay coordination

- 4. Types of Short-Circuit Faults ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 4

- 5. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 5 Types of SC Faults •Three-Phase Ungrounded Fault •Three-Phase Grounded Fault •Phase to Phase Ungrounded Fault •Phase to Phase Grounded Fault •Phase to Ground Fault Fault Current •IL -G can range in utility systems from a few percent to possibly 115 % ( if Xo < X1 ) of I3 -p h a s e (85% of all faults). •In industrial systems the situation IL -G > I3 -p h a s e is rare. Typically IL -G ≅ .87 * I3 -p h a s e •In an industrial system, the three-phase fault condition is frequently the only one considered, since this type of fault generally results in Maximum current. Types of Short-Circuit Faults

- 6. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 6 ) t Sin( Vm v(t) θ ω + ∗ = i(t) v(t) Short-Circuit Phenomenon

- 7. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 7 Offset) (DC Transient State Steady t ) - sin( Z Vm ) - t sin( Z Vm i(t) (1) ) t Sin( Vm dt di L Ri v(t) L R - e × × + + × = + × = + = φ θ φ θ ω θ ω expression following the yields 1 equation Solving i(t) v(t)

- 8. DC Current AC Current (Symmetrical) with No AC Decay ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 8

- 9. AC Fault Current Including the DC Offset (No AC Decay) ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 9

- 10. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 10 Machine Reactance ( λ = L I ) AC Decay Current

- 11. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 11 Fault Current Including AC & DC Decay

- 12. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 12 IEC Short-Circuit Calculation (IEC 909) • Initial Symmetrical Short-Circuit Current (I"k) • Peak Short-Circuit Current (ip) • Symmetrical Short-Circuit Breaking Current (Ib) • Steady-State Short-Circuit Current (Ik)

- 13. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 13 IEC Short-Circuit Calculation Method • Ik” = Equivalent V @ fault location divided by equivalent Z • Equivalent V is based bus nominal kV and c factor • XFMR and machine Z adjusted based on cmax, component Z & operating conditions

- 14. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 14 Transformer Z Adjustment • KT -- Network XFMR • KS,KSO – Unit XFMR for faults on system side • KT,S,KT,SO – Unit XFMR for faults in auxiliary system, not between Gen & XFMR • K=1– Unit XFMR for faults between Gen & XFMR

- 15. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 15 Syn Machine Z Adjustment • KG – Synchronous machine w/o unit XFMR • KS,KSO – With unit XFMR for faults on system side • KG,S,KG,SO – With unit XFMR for faults in auxiliary system, including points between Gen & XFMR

- 16. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 16 Types of Short-Circuits • Near-To-Generator Short-Circuit – This is a short-circuit condition to which at least one synchronous machine contributes a prospective initial short-circuit current which is more than twice the generator’s rated current, or a short-circuit condition to which synchronous and asynchronous motors contribute more than 5% of the initial symmetrical short-circuit current ( I"k) without motors.

- 17. Near-To-Generator Short-Circuit ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 17

- 18. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 18 Types of Short-Circuits • Far-From-Generator Short-Circuit – This is a short-circuit condition during which the magnitude of the symmetrical ac component of available short-circuit current remains essentially constant.

- 19. Far-From-Generator Short-Circuit ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 19

- 20. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 20 Factors Used in If Calc • κ– calc ip based on Ik” • μ– calc ib for near-to-gen & not meshed network • q– calc induction machine ib for near-to-gen & not meshed network • Equation (75) of Std 60909-0, adjusting Ik for near-to-gen & meshed network • λmin & λmax – calc ik

- 21. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 21 IEC Short-Circuit Study Case

- 22. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 22 Types of Short-Circuits • Maximum voltage factor is used • Minimum impedance is used (all negative tolerances are applied and minimum resistance temperature is considered) When these options are selected

- 23. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 23 Types of Short-Circuits • Minimum voltage factor is used • Maximum impedance is used (all positive tolerances are applied and maximum resistance temperature is considered) When this option is selected

- 24. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 24 Voltage Factor (c) • Ratio between equivalent voltage & nominal voltage • Required to account for: • Variations due to time & place • Transformer taps • Static loads & capacitances • Generator & motor subtransient

- 25. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 25 Calculation Method • Breaking kA is more conservative if the option No Motor Decay is selected

- 26. IEC SC 909 Calculation ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 26

- 27. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 27 Device Duty Comparison

- 28. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 28 Mesh & Non-Mesh If • ETAP automatically determines mesh & non-meshed contributions according to individual contributions • IEC Short Circuit Mesh Determination Method – 0, 1, or 2 (default)

- 29. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 29 L-G Faults L-G Faults

- 30. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 30 Symmetrical Components L-G Faults

- 31. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 31 Sequence Networks

- 32. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 32 0 Z Z Z V 3 I I 3 I 0 2 1 efault Pr f a f 0 = + + × = × = g Z if L-G Fault Sequence Network Connections

- 33. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 33 2 1 efault Pr f a a Z Z V 3 I I I 1 2 + × = − = L-L Fault Sequence Network Connections

- 34. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 34 0 Z Z Z Z Z V I I 0 I I I 2 0 2 0 1 efault Pr f a a a a 0 1 2 = + + = = = + + g Z if L-L-G Fault Sequence Network Connections

- 35. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 35 Transformer Zero Sequence Connections

- 36. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 36 grounded. solidly are er transform Connected Y/ or Generators if case the be may This I : then true are conditions this If & : if greater be can faults G - L case. severe most the is fault phase - 3 a Generally 1 f3 1 0 2 1 ∆ < < = φ φ f I Z Z Z Z Solid Grounded Devices and L-G Faults

- 37. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 37 Zero Sequence Model • Branch susceptances and static loads including capacitors will be considered when this option is checked • Recommended by IEC for systems with isolated neutral, resonant earthed neutrals & earthed neutrals with earth fault factor > 1.4

- 38. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 38 Complete reports that include individual branch contributions for: •L-G Faults •L-L-G Faults •L-L Faults One-line diagram displayed results that include: •L-G/L-L-G/L-L fault current contributions •Sequence voltage and currents •Phase Voltages Unbalanced Faults Display & Reports

- 39. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 39 Total Fault Current Waveform Transient Fault Current Calculation (IEC 61363)

- 40. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 40 Percent DC Current Waveform Transient Fault Current Calculation (IEC 61363)

- 41. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 41 AC Component of Fault Current Waveform Transient Fault Current Calculation (IEC 61363)

- 42. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 42 Top Envelope of Fault Current Waveform Transient Fault Current Calculation (IEC 61363)

- 43. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 43 Top Envelope of Fault Current Waveform Transient Fault Current Calculation (IEC 61363)

- 44. IEC Transient Fault Current Calculation ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 44

- 45. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 45 Complete reports that include individual branch contributions for: •L-G Faults •L-L-G Faults •L-L Faults One-line diagram displayed results that include: •L-G/L-L-G/L-L fault current contributions •Sequence voltage and currents •Phase Voltages Unbalanced Faults Display & Reports

- 46. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 46

- 47. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 47

- 48. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 48 TEMA 2

- 49. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Protective Device Coordination ETAP Star

- 50. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 50 ETAP START PROTECCION Y COORDINACION Curvas para más de 75,000 dispositivos. Actualización automática de Corriente de Corto Circuito. Coordinación tiempo-corriente de dispositivos. Auto-coordinación de dispositivos. Integrados a los diagramas unifilares. Rastreo o cálculos en diferentes tiempos. Características principales:

- 51. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 51

- 52. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 52 Agenda • Concepts & Applications • Star Overview • Features & Capabilities • Protective Device Type • TCC Curves • STAR Short-circuit • PD Sequence of Operation • Normalized TCC curves • Device Libraries

- 53. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 53 Definition • Overcurrent Coordination – A systematic study of current responsive devices in an electrical power system.

- 54. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 54 Objective • To determine the ratings and settings of fuses, breakers, relay, etc. • To isolate the fault or overloads.

- 55. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 55 Criteria • Economics • Available Measures of Fault • Operating Practices • Previous Experience

- 56. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 56 Design • Open only PD nearest (upstream) of the fault or overload • Provide satisfactory protection for overloads • Interrupt SC as rapidly (instantaneously) as possible • Comply with all applicable standards and codes • Plot the Time Current Characteristics of different PDs

- 57. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 57 Analysis When: • New electrical systems • Plant electrical system expansion/retrofits • Coordination failure in an existing plant

- 58. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 58 Spectrum Of Currents • Load Current – Up to 100% of full-load – 115-125% (mild overload) • Overcurrent – Abnormal loading condition (Locked-Rotor) • Fault Current – Fault condition – Ten times the full-load current and higher

- 59. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 59 Protection • Prevent injury to personnel • Minimize damage to components – Quickly isolate the affected portion of the system – Minimize the magnitude of available short-circuit

- 60. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 60 Coordination • Limit the extent and duration of service interruption • Selective fault isolation • Provide alternate circuits

- 61. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 61 Coordination t I C B A C D D B A

- 62. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 62 Protection vs. Coordination • Coordination is not an exact science • Compromise between protection and coordination – Reliability – Speed – Performance – Economics – Simplicity

- 63. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 63 Required Data • One-line diagrams (Relay diagrams) • Power Grid Settings • Generator Data • Transformer Data – Transformer kVA, impedance, and connection Motor Data • Load Data • Fault Currents • Cable / Conductor Data • Bus / Switchgear Data • Instrument Transformer Data (CT, PT) • Protective Device (PD) Data – Manufacturer and type of protective devices (PDs) – One-line diagrams (Relay diagrams)

- 64. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 64 Study Procedure • Prepare an accurate one-line diagram (relay diagrams) • Obtain the available system current spectrum (operating load, overloads, fault kA) • Determine the equipment protection guidelines • Select the appropriate devices / settings • Plot the fixed points (damage curves, …) • Obtain / plot the device characteristics curves • Analyze the results

- 65. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 65 Time Current Characteristics • TCC Curve / Plot / Graphs • 4.5 x 5-cycle log-log graph • X-axis: Current (0.5 – 10,000 amperes) • Y-axis: Time (.01 – 1000 seconds) • Current Scaling (…x1, x10, x100, x100…) • Voltage Scaling (plot kV reference) • Use ETAP Star Auto-Scale

- 66. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 66

- 67. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 67 TCC Scaling Example • Situation: – A scaling factor of 10 @ 4.16 kV is selected for TCC curve plots. • Question – What are the scaling factors to plot the 0.48 kV and 13.8 kV TCC curves?

- 68. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 68 TCC Scaling Example • Solution

- 69. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 69 Fixed Points • Cable damage curves • Cable ampacities • Transformer damage curves & inrush points • Motor starting curves • Generator damage curve / Decrement curve • SC maximum fault points Points or curves which do not change regardless of protective device settings:

- 70. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 70 Capability / Damage Curves t I I2 2 t Gen I2 t Motor Xfmr I2 t Cable I2 t

- 71. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 71 Cable Protection • Standards & References – IEEE Std 835-1994 IEEE Standard Power Cable Ampacity Tables – IEEE Std 848-1996 IEEE Standard Procedure for the Determination of the Ampacity Derating of Fire-Protected Cables – IEEE Std 738-1993 IEEE Standard for Calculating the Current- Temperature Relationship of Bare Overhead Conductors – The Okonite Company Engineering Data for Copper and Aluminum Conductor Electrical Cables, Bulletin EHB-98

- 72. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 72 Cable Protection 2 2 1 t A T 234 0.0297log T 234 Ι = + + The actual temperature rise of a cable when exposed to a short circuit current for a known time is calculated by: Where: A= Conductor area in circular-mils I = Short circuit current in amps t = Time of short circuit in seconds T1 = Initial operation temperature (750 C) T2 =Maximum short circuit temperature (1500 C)

- 73. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 73 Cable Short-Circuit Heating Limits Recommended temperature rise: B) CU 75-200C

- 74. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 74 Shielded Cable The normal tape width is 1½ inches

- 75. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 75 NEC Section 110 14 C ‑ • (c) Temperature limitations. The temperature rating associated with the ampacity of a conductor shall be so selected and coordinated as to not exceed the lowest temperature rating of any lowest temperature rating of any connected termination connected termination, conductor, or device. Conductors with temperature ratings higher than specified for terminations shall be permitted to be used for ampacity adjustment, correction, or both. • (1) Termination provisions of equipment for circuits rated 100 amperes or less, or marked for Nos. 14 through 1 conductors, shall be used only for conductors rated 600C (1400F). • Exception No. 1: Conductors with higher temperature ratings shall be permitted to be used, provided the ampacity of such conductors is determined based on the 6O0C (1400F) ampacity of the conductor size used. • Exception No. 2: Equipment termination provisions shall be permitted to be used with higher rated conductors at the ampacity of the higher rated conductors, provided the equipment is listed and identified for use with the higher rated conductors. • (2) Termination provisions of equipment for circuits rated over 100 amperes, or marked for conductors larger than No. 1, shall be used only with conductors rated 750C (1670F).

- 76. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 76 Transformer Protection • Standards & References – National Electric Code 2002 Edition – C37.91-2000; IEEE Guide for Protective Relay Applications to Power Transformers – C57.12.59; IEEE Guide for Dry-Type Transformer Through-Fault Current Duration. – C57.109-1985; IEEE Guide for Liquid-Immersed Transformer Through- Fault-Current Duration – APPLIED PROCTIVE RELAYING; J.L. Blackburn; Westinghouse Electric Corp; 1976 – PROTECTIVE RELAYING, PRINCIPLES AND APPLICATIONS; J.L. Blackburn; Marcel Dekker, Inc; 1987 – IEEE Std 242-1986; IEEE Recommended Practice for Protection and Coordination of Industrial and Commercial Power Systems –

- 77. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 77 Transformer Category ANSI/IEEE C-57.109

- 78. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 78 Transformer Categories I, II

- 79. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 79 Transformer Categories III

- 80. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 80 Transformer t (sec) I (pu) Thermal 200 2.5 I 2 t = 1250 2 25 Isc Mechanical K=(1/Z) 2 t (D-D LL) 0.87 (D-R LG) 0.58 Frequent Fault Infrequent Fault Inrush FLA

- 81. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 81

- 82. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 82 Transformer Protection M Any Location – Non-Supervised

- 83. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 83 Transformer Protection • Turn on or inrush current • Internal transformer faults • External or through faults of major magnitude • Repeated large motor starts on the transformer. The motor represents a major portion or the transformers KVA rating. • Harmonics • Over current protection – Device 50/51 • Ground current protection – Device 50/51G • Differential – Device 87 • Over or under excitation – volts/ Hz – Device 24 • Sudden tank pressure – Device 63 • Dissolved gas detection • Oil Level • Fans • Oil Pumps • Pilot wire – Device 85 • Fault withstand • Thermal protection – hot spot, top of oil temperature, winding temperature • Devices 26 & 49 • Reverse over current – Device 67 • Gas accumulation – Buckholz relay • Over voltage –Device 59 • Voltage or current balance – Device 60 • Tertiary Winding Protection if supplied • Relay Failure Scheme • Breaker Failure Scheme

- 84. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 84 Recommended Minimum Transformer Protection Protective system Winding and/or power system grounded neutral grounded Winding and/or power system neutral ungrounded Up to 10 MVA Above 10 MVA Up to 10 MVA Above 10 MVA Differential - √ - √ Time over current √ √ √ √ Instantaneous restricted ground fault √ √ - - Time delayed ground fault √ √ - - Gas detection √ - √ Over excitation - √ √ √ Overheating - √ - √

- 85. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 85 Question What is ANSI Shift Curve?

- 86. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 86 Answer • For delta-delta connected transformers, with line-to-line faults on the secondary side, the curve must be reduced to 87% (shift to the left by a factor of 0.87) • For delta-wye connection, with single line-to- ground faults on the secondary side, the curve values must be reduced to 58% (shift to the left by a factor of 0.58)

- 87. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 87 Question What is meant by Frequent and Infrequent for transformers?

- 88. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 88 Infrequent Fault Incidence Zones for Category II & III Transformers * Should be selected by reference to the frequent -fault-incidence protection curve or for transformers serving industrial, commercial and institutional power systems with secondary -side conductors enclosed in conduit, bus duct, etc., the feeder protective device may be selected by reference to the infrequent -fault-incidence protection curve. Source: IEEE C57 Source Transformer primary -side protective device (fuses, relayed circuit breakers, etc.) may be selected by reference to the infrequent -fault- incidence protection curve Category II or III Transformer Fault will be cleared by transformer primary -side protective device Optional main secondary –side protective device. May be selected by reference to the infrequent -fault- incidence protection curve Feeder protective device Fault will be cleared by transformer primary -side protective device or by optional main secondary - side protection device Fault will be cleared by feeder protective device Infrequent -Fault Incidence Zone* Feeders Frequent -Fault Inciden ce Zone*

- 89. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 89 Motor Protection • Standards & References – IEEE Std 620-1996 IEEE Guide for the Presentation of Thermal Limit Curves for Squirrel Cage Induction Machines. – IEEE Std 1255-2000 IEEE Guide for Evaluation of Torque Pulsations During Starting of Synchronous Motors – ANSI/ IEEE C37.96-2000 Guide for AC Motor Protection – The Art of Protective Relaying – General Electric

- 90. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 90 Motor Protection • Motor Starting Curve • Thermal Protection • Locked Rotor Protection • Fault Protection

- 91. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 91 Motor Overload Protection (NEC Art 430-32 – Continuous-Duty Motors) • Thermal O/L (Device 49) • Motors with SF not less than 1.15 – 125% of FLA • Motors with temp. rise not over 40°C – 125% of FLA • All other motors – 115% of FLA

- 92. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 92 Motor Protection – Inst. Pickup LOCKED ROTOR S d 1 I X X " = + PICK UP LOCKED ROTOR I RELAY PICK UP 1.2 TO 1.2 I = ∗ PICK UP LOCKED ROTOR I RELAY PICK UP 1.6 TO 2 I = ∗ with a time delay of 0.10 s (six cycles at 60 Hz) Recommended Instantaneous Setting: If the recommended setting criteria cannot be met, or where more sensitive protection is desired, the in-stantaneous relay (or a second relay) can be set more sensitively if delayed by a timer. This permits the asymmetrical asymmetrical starting component to decay out. A typical setting for this is:

- 93. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 93 Locked Rotor Protection • Thermal Locked Rotor (Device 51) • Starting Time (TS < TLR) • LRA – LRA sym – LRA asym (1.5-1.6 x LRA sym) + 10% margin

- 94. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 94 Fault Protection (NEC Art / Table 430-52) • Non-Time Delay Fuses – 300% of FLA • Dual Element (Time-Delay Fuses) – 175% of FLA • Instantaneous Trip Breaker – 800% - 1300% of FLA* • Inverse Time Breakers – 250% of FLA *can be set up to 1700% for Design B (energy efficient) Motor

- 95. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 95 Low Voltage Motor Protection • Usually pre-engineered (selected from Catalogs) • Typically, motors larger than 2 Hp are protected by combination starters • Overload / Short-circuit protection

- 96. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 96 Low-voltage Motor Ratings Range of ratings Continuous amperes 9-250 — Nominal voltage (V) 240-600 — Horsepower 1.5-1000 — Starter size (NEMA) — 00-9 Types of protection Quantity NEMA designation Overload: overload relay elements 3 OL Short circuit: circuit breaker current trip elements 3 CB Fuses 3 FU Undervoltage: inherent with integral control supply and three-wire control circuit — — Ground fault (when speci-fied): ground relay with toroidal CT — —

- 97. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 97 Minimum Required Sizes of a NEMA Combination Motor Starter System R HP C FLC TER E UM

- 98. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 98 Required Data - Protection of a Medium Voltage Motor • Rated full load current • Service factor • Locked rotor current • Maximum locked rotor time (thermal limit curve) with the motor at ambient and/or operating temperature • Minimum no load current • Starting power factor • Running power factor • Motor and connected load accelerating time • System phase rotation and nominal frequency • Type and location of resistance temperature devices (RTDs), if used • Expected fault current magnitudes • First ½ cycle current • Maximum motor starts per hour

- 99. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 99 Medium-Voltage Class E Motor Controller Ratings Class El (without fuses) Class E2 (with fuses) Nominal system voltage 2300-6900 2300-6900 Horsepower 0-8000 0-8000 Symmetrical MVA interrupting capacity at nominal system voltage 25-75 160-570 Types of Protective Devices Quantity NEMA Designation Overload, or locked Rotor, or both: Thermal overload relay TOC relay IOC relay plus time delay 3 3 3 OL OC TR/O Thermal overload relay 3 OL TOC relay 3 OC IOC relay plus time delay 3 TR/OC Short Circuit: Fuses, Class E2 3 FU IOC relay, Class E1 3 OC Ground Fault TOC residual relay 1 GP Overcurrent relay with toroidal CT 1 GP NEMA Class E2 medium voltage starter NEMA Class E1 medium voltage starter Phase Balance Current balance relay 1 BC Negative-sequence voltage relay (per bus), or both 1 — Undervoltage: Inherent with integral control supply and three- wire control circuit, when voltage falls suffi-ciently to permit the contractor to open and break the seal-in circuit — UV Temperature: Temperature relay, operating from resistance sensor or ther-mocouple in stator winding — OL

- 100. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 100 Starting Current of a 4000Hp, 12 kV, 1800 rpm Motor First half cycle current showing current offset. Beginning of run up current showing load torque pulsations.

- 101. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 101 Starting Current of a 4000Hp, 12 kV, 1800 rpm Motor - Motor pull in current showing motor reaching synchronous speed Oscillographs

- 102. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 102 Thermal Limit Curve

- 103. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 103 Thermal Limit Curve Typical Curve

- 104. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 104 200 HP MCP O/L Starting Curve I2 T (49) MCP (50) (51) ts tL R LRAs LRAasy m

- 105. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 105 Protective Devices • Fuse • Overload Heater • Thermal Magnetic • Low Voltage Solid State Trip • Electro-Mechanical • Motor Circuit Protector (MCP) • Relay (50/51 P, N, G, SG, 51V, 67, 49, 46, 79, 21, …)

- 106. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 106 Fuse (Power Fuse) • Non Adjustable Device (unless electronic) • Continuous and Interrupting Rating • Voltage Levels (Max kV) • Interrupting Rating (sym, asym) • Characteristic Curves – Min. Melting – Total Clearing • Application (rating type: R, E, X, …)

- 107. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 107 Fuse Types • Expulsion Fuse (Non-CLF) • Current Limiting Fuse (CLF) • Electronic Fuse (S&C Fault Fiter)

- 108. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 108 Minimum Melting Time Curve Total Clearing Time Curve

- 109. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 109 Current Limiting Fuse (CLF) • Limits the peak current of short-circuit • Reduces magnetic stresses (mechanical damage) • Reduces thermal energy

- 110. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 110 Current Limiting Action Current (peak amps) tm ta Ip ’ Ip tc ta = tc – tm ta = Arcing Time tm = Melting Time tc = Clearing Time Ip = Peak Current Ip ’ = Peak Let-thru Current Time (cycles)

- 111. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 111 © 1996-2009 Operation Technology, Inc. – Workshop Notes: Protective Device Coordination

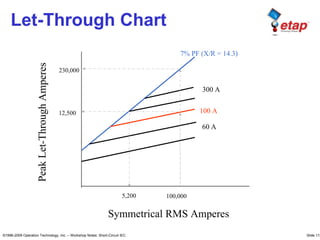

- 112. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 112 Symmetrical RMS Amperes Peak Let-Through Amperes 100 A 60 A 7% PF (X/R = 14.3) 12,500 5,200 230,000 300 A 100,000 Let-Through Chart

- 113. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 113 Fuse Generally: • CLF is a better short-circuit protection • Non-CLF (expulsion fuse) is a better Overload protection • Electronic fuses are typically easier to coordinate due to the electronic control adjustments

- 114. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 114 Selectivity Criteria Typically: • Non-CLF: 140% of full load • CLF: 150% of full load • Safety Margin: 10% applied to Min Melting (consult the fuse manufacturer)

- 115. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 115 Molded Case CB • Thermal-Magnetic • Magnetic Only • Motor Circuit Protector (MCP) • Integrally Fused (Limiters) • Current Limiting • High Interrupting Capacity • Non-Interchangeable Parts • Insulated Case (Interchange Parts) Types • Frame Size • Poles • Trip Rating • Interrupting Capability • Voltage

- 116. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 116 MCCB

- 117. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 117 MCCB with SST Device

- 118. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 118 Thermal Minimum Thermal Maximum Magnetic (instantaneous)

- 119. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 119 LVPCB • Voltage and Frequency Ratings • Continuous Current / Frame Size / Sensor • Interrupting Rating • Short-Time Rating (30 cycle) • Fairly Simple to Coordinate • Phase / Ground Settings • Inst. Override

- 120. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 120 CB 2 CB 1 IT ST PU ST Band LT PU LT Band 480 kV CB 2 CB 1 If =30 kA

- 121. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 121 Inst. Override

- 122. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 122 Overload Relay / Heater • Motor overload protection is provided by a device that models the temperature rise of the winding • When the temperature rise reaches a point that will damage the motor, the motor is de- energized • Overload relays are either bimetallic, melting alloy or electronic

- 123. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 123 Overload Heater (Mfr. Data)

- 124. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 124 Question What is Class 10 and Class 20 Thermal OLR curves?

- 125. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 125 Answer • At 600% Current Rating: – Class 10 for fast trip, 10 seconds or less – Class 20 for, 20 seconds or less (commonly used) – There is also Class 15, 30 for long trip time (typically provided with electronic overload relays) 6 20

- 126. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 126 Answer

- 127. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 127 Overload Relay / Heater • When the temperature at the combination motor starter is more than ±10 °C (±18 °F) different than the temperature at the motor, ambient temperature correction of the motor current is required. • An adjustment is required because the output that a motor can safely deliver varies with temperature. • The motor can deliver its full rated horsepower at an ambient temperature specified by the motor manufacturers, normally + 40 °C. At high temperatures (higher than + 40 °C) less than 100% of the normal rated current can be drawn from the motor without shortening the insulation life. • At lower temperatures (less than + 40 °C) more than 100% of the normal rated current could be drawn from the motor without shortening the insulation life.

- 128. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 128 Overcurrent Relay • Time-Delay (51 – I>) • Short-Time Instantaneous ( I>>) • Instantaneous (50 – I>>>) • Electromagnetic (induction Disc) • Solid State (Multi Function / Multi Level) • Application

- 129. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 129 © 1996-2009 Operation Technology, Inc. – Workshop Notes: Protective Device Coordination

- 130. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 130 Time-Overcurrent Unit • Ampere Tap Calculation – Ampere Pickup (P.U.) = CT Ratio x A.T. Setting – Relay Current (IR) = Actual Line Current (IL) / CT Ratio – Multiples of A.T. = IR/A.T. Setting = IL/(CT Ratio x A.T. Setting) IL IR CT 51

- 131. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 131 Instantaneous Unit • Instantaneous Calculation – Ampere Pickup (P.U.) = CT Ratio x IT Setting – Relay Current (IR) = Actual Line Current (IL) / CT Ratio – Multiples of IT = IR/IT Setting = IL/(CT Ratio x IT Setting) IL IR CT 50

- 132. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 132 Relay Coordination • Time margins should be maintained between T/C curves • Adjustment should be made for CB opening time • Shorter time intervals may be used for solid state relays • Upstream relay should have the same inverse T/C characteristic as the downstream relay (CO-8 to CO-8) or be less inverse (CO-8 upstream to CO-6 downstream) • Extremely inverse relays coordinates very well with CLFs

- 133. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 133 Situation Calculate Relay Setting (Tap, Inst. Tap & Time Dial) For This System 4.16 kV DS 5 MVA Cable 1-3/C 500 kcmil CU - EPR CB Isc = 30,000 A 6 % 50/51 Relay: IFC 53 CT 800:5

- 134. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 134 Solution A Inrsuh 328 , 8 694 12 I = × = A 338 . 4 800 5 I I L R = × = Transformer: A kV kVA L 694 16 . 4 3 000 , 5 I = × = IL CT R IR Set Relay: A 55 1 . 52 800 5 328 , 8 ) 50 ( 1 ) 38 . 1 (6/4.338 0 . 6 4 . 5 338 . 4 % 125 = > = × = = = = × = A Inst TD A TAP A

- 135. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 135 Question What T/C Coordination interval should be maintained between relays?

- 136. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 136 Answer A t I B CB Opening Time + Induction Disc Overtravel (0.1 sec) + Safety margin (0.2 sec w/o Inst. & 0.1 sec w/ Inst.)

- 137. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 137 Recloser • Recloser protects electrical transmission systems from temporary voltage surges and other unfavorable conditions. • Reclosers can automatically "reclose" the circuit and restore normal power transmission once the problem is cleared. • Reclosers are usually designed with failsafe mechanisms that prevent them from reclosing if the same fault occurs several times in succession over a short period. This insures that repetitive line faults don't cause power to switch on and off repeatedly, since this could cause damage or accelerated wear to electrical equipment. • It also insures that temporary faults such as lightning strikes or transmission switching don't cause lengthy interruptions in service.

- 138. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 138 Recloser Types • Hydraulic • Electronic – Static Controller – Microprocessor Controller

- 139. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 139 Recloser Curves

- 140. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 140 TEMA 3

- 141. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Transient Stability

- 142. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 142 Topics • What is Transient Stability (TS) • What Causes System Unstable • Effects When System Is Instable • Transient Stability Definition • Modeling and Data Preparation • ETAP TS Study Outputs • Power System TS Studies • Solutions to Stability Problems

- 143. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 143 What is Transient Stability • TS is also called Rotor Angle Stability Something between mechanical system and electrical system – energy conversion • It is a Electromechanical Phenomenon Time frame in milliseconds • All Synchronous Machines Must Remain in Synchronism with One Another Synchronous generators and motors This is what system stable or unstable means

- 144. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 144 What is Transient Stability • Torque Equation (generator case) T = mechanical torque P = number of poles φ a ir = air-gap flux Fr = rotor field MMF δ = rotor angle

- 145. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 145 What is Transient Stability • Swing Equation M = inertia constant D = damping constant Pm e c h = input mechanical power Pe le c = output electrical power

- 146. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 146 What Causes System Unstable • From Torque Equation T (prime mover) Rotor MMF (field winding) Air-Gap Flux (electrical system) • From Swing Equation Pmech Pelec Different time constants in mechanical and electrical systems

- 147. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 147 What Causes System Unstable • In real operation Short-circuit Loss of excitation Prime mover failure Loss of utility connections Loss of a portion of in-plant generation Starting of a large motor Switching operations Impact loading on motors Sudden large change in load and generation

- 148. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 148 Effects When System Is Instable Case 1: Steady-state stable Case 2: Transient stable Case 3: Small-signal unstable Case 4: First swing unstable • Swing in Rotor Angle (as well as in V, I, P, Q and f)

- 149. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 149 Effects When System Is Instable • A 2-Machine Example • At δ = -180º (Out-of-Step, Slip the Pole)

- 150. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 150 Effects When System Is Instable • Synchronous machine slip poles – generator tripping • Power swing • Misoperation of protective devices • Interruption of critical loads • Low-voltage conditions – motor drop-offs • Damage to equipment • Area wide blackout • …

- 151. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 151 • Examine One Generator • Power Output Capability Curve ∀ δ is limited to 180º Transient Stability Definition

- 152. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 152 Transient Stability Definition • Transient and Dynamic Stability Limit After a severe disturbance, the synchronous generator reaches a steady-state operating condition without a prolonged loss of synchronism Limit: δ < 180°during swing

- 153. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 153 • Synchronous Machine Machine Exciter and AVR Prime Mover and Governor / Load Torque Power System Stabilizer (PSS) (Generator) Modeling and Data Preparation

- 154. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 154 Modeling and Data Preparation

- 155. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 155 Modeling and Data Preparation • Typical synchronous machine data

- 156. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 156 Modeling and Data Preparation • Induction Machine Machine Load Torque

- 157. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 157 Modeling and Data Preparation • Power Grid Short-Circuit Capability Fixed internal voltage and infinite inertia

- 158. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 158 Modeling and Data Preparation • Load Voltage dependency Frequency dependency

- 159. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 159 Modeling and Data Preparation • Load

- 160. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 160 Modeling and Data Preparation • Events and Actions

- 161. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 161 Modeling and Data Preparation Device Type Action Bus 3-P Fault L-G Fault Clear Fault Branch Fraction Fault Clear Fault PD Trip Close Generator Droop / Isoch Start Loss Exc. P Change V Change Delete Grid P Change V Change Delete Motor Accelerate Load Change Delete Lumped Load Load Change Delete MOV Start Wind Turbine Disturbance Gust Ramp MG Set Emergency Main

- 162. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 162 Power System TS Studies • Fault 3-phase and single phase fault Clear fault Critical Fault Clearing Time (CFCT) Critical System Separation Time (CSST) • Bus Transfer Fast load transferring • Load Shedding Under-frequency Under-voltage • Motor Dynamic Acceleration Induction motor Synchronous motor

- 163. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 163 Power System TS Studies • Critical Fault Clearing Time (CFCT) • Critical Separation Time (CSST) unstable unstable Cycle Clear fault Clear fault 1 cycle unstable stable 1 cycle Clear fault Clear fault CFCT Fault unstable unstable Cycle 1 cycle unstable stable 1 cycle CSST Separation Separation Separation Separation Fault

- 164. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 164 Power System TS Studies -1 -0.8 -0.6 -0.4 -0.2 0 0.2 0.4 0.6 0.8 1 -1 -0.8 -0.6 -0.4 -0.2 0 0.2 0.4 0.6 0.8 1 Vmotor s • Fast Bus Transfer Motor residual voltage

- 165. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 165 • Fast Bus Transfer Ttra n s fe r ≤ 10 cycles δ ≤ 90 degrees ER ≤ 1.33 per unit (133%) Power System TS Studies ES = System equivalent per unit volts per hertz EM = Motor residual per unit per hertz ER = Resultant vectorial voltage in per unit volts per hertz δ

- 166. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 166 Power System TS Studies • Load Shedding

- 167. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 167 Power System TS Studies • Motor Dynamic Acceleration Important for islanded system operation Motor starting impact Generator AVR action Reacceleration

- 168. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 168 • Improve System Design Increase synchronizing power • Design and Selection of Rotating Equipment Use of induction machines Increase moment of inertia Reduce transient reactance Improve voltage regulator and exciter characteristics Solution to Stability Problems

- 169. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 169 • Application of Power System Stabilizer (PSS) • Add System Protections Fast fault clearance Load shedding System separation Out-Of-Step relay … Solution to Stability Problems

- 170. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC

- 171. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 171 TEMA 4

- 172. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Harmonic Analysis

- 173. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 173 ARMONICAS Exploración de frecuencia. Flujo Armónico de Carga. Dimensionamiento y Diseño de Filtros. Evaluación Automática del límite de distorsión. Factores de la influencia del teléfono (TIF & I*T) Características principales:

- 174. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 174

- 175. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 175 Types of Power Quality Problems

- 176. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 176 Waveform Distortion • Primary Types of Waveform Distortion – DC Offset – Harmonics – Interharmonics – Notching – Noise

- 177. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 177 Harmonics • One special category of power quality problems • “Harmonics are voltages and/or currents present in an electrical system at some multiple of the fundamental frequency.” (IEEE Std 399, Brown Book)

- 178. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 178 Nonlinear Loads • Sinusoidal voltage applied to a simple nonlinear resistor • Increasing the voltage by a few percent may cause current to double

- 179. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 179 Fourier Representation • Any periodic waveform can be expressed as a sum of sinusoids • The sum of the sinusoids is referred to as Fourier Series (6-pulse) ) cos( 13 cos 13 1 11 cos 11 1 7 cos 7 1 3 cos 5 1 (cos 3 2 1 h h h d ac t h I t t t t t I I Φ + ⇒ + − + − = ∑ ∞ = ω ω ω ω ω ω π

- 180. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 180 Harmonic Sources • Utilities (Power Grid) – Known as “Background Harmonic” – Pollution from other irresponsible customers – SVC, HVDC, FACTS, … – Usually a voltage source • Synchronous Generators – Due to Pitch (can be eliminated by fractional- pitch winding) and Saturation – Usually a voltage source

- 181. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 181 Harmonic Sources (cont’d) • Transformers – Due to magnetizing branch saturation – Only at lightly loaded condition – Usually a current source • Power Electronic Devices – Charger, Converter, Inverter, UPS, VFD, SVC, HVDC, FACTS (Flexible alternating current transmission systems) … – Due to switching actions – Either a voltage source or a current source

- 182. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 182 Harmonic Sources (cont’d) • Other Non-Linear Loads – Arc furnaces, discharge lighting, … – Due to unstable and non-linear process – Either a voltage source or a current source • In general, any load that is applied to a power system that requires other than a sinusoidal current

- 183. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 183 Harmonic I and V

- 184. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 184 Classification of Harmonics • Harmonics may be classified as: – Characteristic Harmonics Generally produced by power converters – Non-Characteristic Harmonics Typically produced by arc furnaces and discharge lighting (from non-periodical waveforms)

- 185. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 185 Phase Angle Relationship • Fundamental Frequency

- 186. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 186 Phase Angle Relationship • Third Order

- 187. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 187 Phase Angle Relationship • Fifth Order • Seventh Order

- 188. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 188 Order vs. Sequence

- 189. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 189 Characteristic Harmonics

- 190. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 190 Characteristic Harmonics (cont’d)

- 191. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 191 Harmonic Spectrum %

- 192. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 192 Harmonic-Related Problems • Motors and Generators – Increased heating due to iron and copper losses – Reduced efficiency and torque – Higher audible noise – Cogging or crawling – Mechanical oscillations

- 193. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 193 Harmonic-Related Problems (cont’d) • Transformers – Parasitic heating – Increased copper, stray flux and iron losses • Capacitors (var compensators) – Possibility of system resonance – Increased heating and voltage stress – Shortened capacitor life

- 194. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 194 Harmonic-Related Problems (cont’d) • Power Cables – Involved in system resonance – Voltage stress and corona leading to dielectric failure – Heating and derating • Neutrals of four-wire systems (480/277V; 120/208V) – Overheating • Fuses – Blowing

- 195. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 195 Harmonic-Related Problems (cont’d) • Switchgears – Increased heating and losses – Reduced steady-state current carrying capability – Shortened insulation components life • Relays – Possibility of misoperation • Metering – Affected readings

- 196. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 196 Harmonic-Related Problems (cont’d) • Communication Systems – Interference by higher frequency electromagnetic field • Electronic Equipment (computers, PLC) – Misoperation • System – Resonance (serial and parallel) – Poor power factor

- 197. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 197 Parallel Resonance • Total impedance at resonance frequency increases • High circulating current will flow in the capacitance-inductance loop

- 198. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 198 Parallel Resonance

- 199. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 199 Capacitor Banks

- 200. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 200 Capacitor Banks

- 201. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 201 Capacitor Banks Say, Seventh Harmonic Current = 5% of 1100A = 55 A

- 202. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 202 Capacitor Banks Resistance = 1% including cable and transformer CAF = X/R = 7*0.0069/0.0012 =40.25 Resonant Current = 55*40.25 = 2214 A

- 203. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 203 Parallel Resonance (cont’d) Cause: Impacts: 1. Excessive capacitor fuse operation 2. Capacitor failures 3. Incorrect relay tripping 4. Telephone interference 5. Overheating of equipment Source inductance resonates with capacitor bank at a frequency excited by the facilities harmonic sources

- 204. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 204 Harmonic Distortion Measurements • Total Harmonic Distortion (THD) – Also known as Harmonic Distortion Factor (HDF), is the most popular index to measure the level of harmonic distortion to voltage and current – Ratio of the RMS of all harmonics to the fundamental component – For an ideal system THD = 0% – Potential heating value of the harmonics relative to the fundamental

- 205. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 205 Harmonic Distortion Measurements (cont’d) 1 2 2 F F THD i ∑ ∞ = Where Fi is the amplitude of the ith harmonic, and F1 is that for the fundamental component. – Good indicator of additional losses due to current flowing through a conductor – Not a good indicator of voltage stress in a capacitor (related to peak value of voltage waveform, not its heating value)

- 206. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 206 Harmonic Distortion Example Find THD for this waveform

- 207. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 207 Harmonic Example • Find THD for this Harmonic Spectrum

- 208. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 208 Adjustable Speed Drive – Current Distortion

- 209. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 209 Adjustable Speed Drive – Voltage Distortion

- 210. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 210 Harmonic Distortion Measurements (cont’d) • Individual Harmonic Distortion (IHD) - Ratio of a given harmonic to fundamental - To track magnitude of individual harmonic 1 F F IHD i = • Root Mean Square (RMS) - Total - Root Mean Square of fundamental plus all harmonics - Equal to fundamental RMS if Harmonics are zero ∑ ∞ = 1 2 i F RMS

- 211. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 211 Harmonic Distortion Measurements (cont’d) • Arithmetic Summation (ASUM) – Arithmetic summation of magnitudes of all components (fundamental and all harmonics) – Directly adds magnitudes of all components to estimate crest value of voltage and current – Evaluation of the maximum withstanding ratings of a device ∑ ∞ = 1 i F ASUM

- 212. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 212 Harmonic Distortion Measurements (cont’d) • Telephone Influence Factor (TIF) – Weighted THD – Weights based on interference to an audio signal in the same frequency range – Current TIF shows impact on adjacent communication systems ( ) 2 1 2 1 ∑ ∑ ∞ ∞ = i i i F F W TIF

- 213. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 213 Harmonic Distortion Measurements (cont’d) • I*T Product (I*T) – A product current components (fundamental and harmonics) and weighting factors ∑ = ⋅ = • H h h h T I T I 1 2 ) ( where Ih = current component Th = weighting factor h = harmonic order (h=1 for fundamental) H = maximum harmonic order to account

- 214. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 214 Triplen Harmonics • Odd multiples of the third harmonic (h = 3, 9, 15, 21, …) • Important issue for grounded-wye systems with neutral current • Overloading and TIF problems • Misoperation of devices due to presence of harmonics on the neutral

- 215. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 215 Triplen Harmonics

- 216. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 216 Winding Connections • Delta winding provides ampere turn balance • Triplen Harmonics cannot flow • When currents are balanced Triplens behave as Zero Sequence currents • Used in Utility Distribution Substations • Delta winding connected to Transmission • Balanced Triplens can flow • Present in equal proportions on both sides • Many loads are served in this fashion

- 217. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 217 Implications • Neutral connections are susceptible to overheating when serving single-phase loads on the Y side that have high 3rd Harmonic • Measuring current on delta side will not show the triplens and therefore do not give a true idea of the heating the transformer is subjected to • The flow of triplens can be interrupted by appropriate isolation transformer connection • Removing the neutral connection in one or both Y windings blocks the flow of Triplen harmonic current • Three legged core transformers behave as if they have a “phantom” delta tertiary winding

- 218. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 218 Modeling in Harmonic Analysis • Motors and Machines – Represented by their equivalent negative sequence reactance • Lines and Cables – Series impedance for low frequencies – Long line correction including transposition and distributed capacitance

- 219. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 219 Modeling in Harmonic Analysis (cont’d) • Transformers – Leakage impedance – Magnetizing impedance • Loads – Static loads reduce peak resonant impedance – Motor loads shift resonant frequency due to motor inductance

- 220. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 220 Reducing System Harmonics • Add Passive Filters – Shunt or Single Tuned Filters – Broadband Filters or Band Pass Filters – Provide low impedance path for harmonic current – Least expensive

- 221. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 221 Reducing System Harmonics (cont’d) • Increase Pulse Numbers – Increasing pulse number of convert circuits – Limited by practical control problems

- 222. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 222 Reducing System Harmonics (cont’d) • Apply Transformer Phase Shifting – Using Phase Shifting Transformers – Achieve higher pulse operation of the total converter installation • In ETAP – Phase shift is specified in the tab page of the transformer editor

- 223. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 223 Reducing System Harmonics (cont’d) • Either standard phase shift or special phase shift can be used

- 224. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 224 Reducing System Harmonics (cont’d) • Add Active Filters – Instantly adapts to changing source and load conditions – Costly – MVA Limitation

- 225. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 225 Voltage Distortion Limits Recommended Practices for Utilities (IEEE 519): Bus Voltage At PCC Individual Distortion (%) Total Voltage Distortion THD (%) 69 kV and below 3.0 5.0 69.001 kV through 161kV 1.5 2.5 161.001 and above 1.0 1.5 In ETAP: Specify Harmonic Distortion Limits in Harmonic Page of Bus Editor:

- 226. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 226 Current Distortion Limits Recommended Practices for General Distribution Systems (IEEE 519):

- 227. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 227 TEMA 5

- 228. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Motor Starting Dynamic Acceleration

- 229. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 229 ARRANQUE DE MOTORES Aceleración dinámica de motores. Parpadeo (Flicker) de tensión. Modelos dinámicos de motores. Arranque estático de motores. Varios dispositivos de arranque. Transición de carga. Características principales:

- 230. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 230

- 231. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 231 Why to Do MS Studies? • Ensure that motor will start with voltage drop • If Ts t <Tlo a d at s=1, then motor will not start • If Tm=Tlo a d at s<sr, motor can not reach rated speed • Torque varies as (voltage)^2 • Ensure that voltage drop will not disrupt other loads • Utility bus voltage >95% • 3% Sag represents a point when light flicker becomes visible • 5% Sag represents a point when light flicker becomes irritating • MCC bus voltage >80% • Generation bus voltage > 93%

- 232. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 232 Why to Do MS Studies? • Ensure motor feeders sized adequately (Assuming 100% voltage at Switchboard or MCC) • LV cable voltage drop at starting < 20% • LV cable voltage drop when running at full-load < 5% • HV cable voltage drop at starting < 15% • HV cable voltage drop when running at full-load < 3% • Maximum motor size that can be started across the line • Motor kW < 1/6 kW rating of generator (islanded) • For 6 MW of islanded generation, largest motor size < 1 MW

- 233. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 233 Motor Sizing • Positive Displacement Pumps / Rotary Pumps • p = Pressure in psi • Q = fluid flow in gpm • n = efficiency • Centrifugal Pumps • H = fluid head in feet

- 234. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 234 Motor Types • Synchronous • Salient Pole • Round Rotor • Induction • Wound Rotor (slip-ring) • Single Cage CKT Model • Squirrel Cage (brushless) • Double Cage CKT Model

- 235. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 235 Induction Motor Advantages • Squirrel Cage • Slightly higher efficiency and power factor • Explosive proof • Wound Rotor • Higher starting torque • Lower starting current • Speed varied by using external resistances

- 236. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 236 Typical Rotor Construction • Rotor slots are not parallel to the shaft but skewed

- 237. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 237 Wound Rotor

- 238. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 238 Operation of Induction Motor • AC applied to stator winding • Creates a rotating stator magnetic field in air gap • Field induces currents (voltages) in rotor • Rotor currents create rotor magnetic field in air gap • Torque is produced by interaction of air gap fields

- 239. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 239 Slip Frequency • Slip represents the inability of the rotor to keep up with the stator magnetic field • Slip frequency S = (ωs-ωn)/ωs where ωs = 120f/P ωn = mech speed

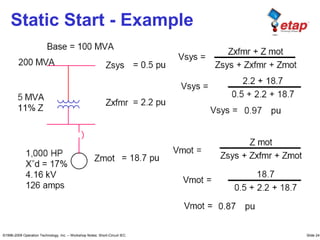

- 240. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 240 Static Start - Example

- 241. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 241 Static Start - Example

- 242. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 242 Service Factor

- 243. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 243 Inrush Current

- 244. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 244 Resistance / Reactance • Torque Slip Curve is changed by altering resistance / reactance of rotor bars. • Resistance ↑ by ↓cross sectional area or using higher resistivity material like brass. • Reactance ↑ by placing conductor deeper in the rotor cylinder or by closing the slot at the air gap.

- 245. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 245 Rotor Bar Resistance ↑ • Increase Starting Torque • Lower Starting Current • Lower Full Load Speed • Lower Efficiency • No Effect on Breakdown Torque

- 246. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 246 Rotor Bar Reactance ↑ • Lower Starting Torque • Lower Starting Current • Lower Breakdown Torque • No effect on Full Load Conditions

- 247. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 247 Motor Torque Curves

- 248. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 248 Rotor Bar Design • Cross section Large (low resistance) and positioned deep in the rotor (high reactance). (Starting Torque is normal and starting current is low). • Double Deck with small conductor of high resistance. During starting, most current flows through the upper deck due to high reactance of lower deck. (Starting Torque is high and starting current is low).

- 249. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 249 Rotor Bar Design • Bars are made of Brass or similar high resistance material. Bars are close to surface to reduce leakage reactance. (Starting torque is high and starting current is low).

- 250. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 250 Load Torque – ID Fan

- 251. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 251 Load Torque – FD Fan

- 252. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 252 Load Torque – C. Pump

- 253. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 253 Motor Torque – Speed Curve

- 254. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 254 Double Cage Motor

- 255. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 255 Motor Full Load Torque • For example, 30 HP 1765 RPM Motor

- 256. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 256 Motor Efficiency • kW Saved = HP * 0.746 (1/Old – 1/New) • $ Savings = kW Saved * Hrs /Year * $/kWh

- 257. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 257 Acceleration Torque • Greater Acceleration Torque means higher inertia that can be handled by the motor without approaching thermal limits

- 258. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 258 Acceleration Torque P

- 259. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 259 Operating Range • Motor, Generator, or Brake

- 260. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 260 0.8 1.0 kvar Load(kva) Terminal Voltage Terminal Current Terminal Voltage 0.8 1.0 P = Tm Wm , As Vt ( terminal voltage ) changes from 0.8 to 1.1 pu, Wm changes by a very small amount. There fore, P is approx constant since Tm (α w²m) is approx. constant L1 Ir Rated Conditions • Constant Power

- 261. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 261 0.9 1.0 Kva LR Terminal Voltage Terminal Voltage 0.9 1.0 .8 kva LR Vt (pu) Vt (pu) .9 I LR I LR P It KVA LR = Loched - rotor KVA at rated voltage = 2HP 2 ≡ Code letter factor ≡ Locked – rotor KVA ∕ HP Z st = KVA B KVR ² KVA LR KVB Pu, Rst = Zst cos θ st , Xst= Zst sin θ st ______ ____ KVR = rated voltage KVB = Base voltage KVAB = Base power Starting Conditions • Constant Impedance Starting Conditions Constant Impedance

- 262. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 262 ws wm v1 p R Load Voltage Variation 0 I 80% voltage 100% voltage ws wm 0 T T st T’ st Tst α ( operating voltage) ² Rated voltage _____________ Rated voltage _____________ Ist α ( operating voltage) • Torque is proportional to V^2 • Current is proportional to V I 80% V 100% V

- 263. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 263 Frequency Variation • As frequency decreases, peak torque shifts toward lower speed as synchronous speed decreases. • As frequency decrease, current increases due reduced impedance. T em WS1 WS2 Wm F1 F2 › F1 0 I WS1 WS2 Wm F1 F2 › F1 0 W3 = 120f P ___ RPM Adjustable speed drive : Typical speed range for variable torque loads such as pumps and fans is 3/1,maximun is 8/1 ( 1.5 to 60 Hz)

- 264. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 264 Number of Poles Variation • As Pole number increases, peak torque shifts toward lower speed as synchronous speed decreases. T em W′S WS Wm 0 2 P - poles P - poles P R Load Nro. of poles variation W′S = WS ___ 2

- 265. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 265 Rotor Z Variation • Increasing rotor Z will shift peak torque towards lower speed. S R Q P r1 r2 r3 r4 r1 › r2 › r3 › r4 Rotor – Resistance Variation

- 266. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 266 Modeling of Elements • Switching motors – Zlr, circuit model, or characteristic model • Synch generator - constant voltage behind X’d • Utility - constant voltage behind X”d • Branches – Same as in Load Flow • Non-switching Load – Same as Load flow • All elements must be initially energized, including motors to start

- 267. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 267 Motor Modeling 1. Operating Motor – Constant KVA Load 1. Starting Motor – During Acceleration – Constant Impedance – Locked-Rotor Impedance – Circuit Models Characteristic Curves After Acceleration – Constant KVA Load

- 268. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 268 Locked-Rotor Impedance • ZLR = RLR +j XLR (10 – 25 %) • PFLR is much lower than operating PD. Approximate starting PF of typical squirrel cage induction motor: POWER FACTOR HORSE POWER RATING

- 269. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 269 Circuit Model I • Single Cage Rotor – “Single1” – constant rotor resistance and reactance

- 270. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 270 Circuit Model II • Single Cage Rotor – “Single2” - deep bar effect, rotor resistance and reactance vary with speed [Xm is removed]

- 271. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 271 Circuit Model III • Double Cage Rotor – “DB1” – integrated rotor cages

- 272. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 272 Circuit Model IV • Double Cage Rotor – “DB2” – independent rotor cages

- 273. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 273 Characteristic Model • Motor Torque, I, and PF as function of Slip – Static Model

- 274. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 274 Calculation Methods I • Static Motor Starting – Time domain using static model – Switching motors modeled as Zlr during starting and constant kVA load after starting – Run load flow when any change in system • Dynamic Motor Starting – Time domain using dynamic model and inertia model – Dynamic model used for the entire simulation – Requires motor and load dynamic (characteristic) model

- 275. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 275 Calculation Methods II

- 276. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 276 Static versus Dynamic • Use Static Model When – Concerned with effect of motor starting on other loads – Missing dynamic motor information • Use Dynamic Model When – Concerned with actual acceleration time – Concerned if motor will actually start

- 277. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 277 MS Simulation Features • Start/Stop induction/synchronous motors • Switching on/off static load at specified loading category • Simulate MOV opening/closing operations • Change grid or generator operating category • Simulate transformer LTC operation • Simulate global load transition • Simulate various types of starting devices • Simulate load ramping after motor acceleration

- 278. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 278 Automatic Alert • Starting motor terminal V • Motor acceleration failure • Motor thermal damage • Generator rating • Generator engine continuous & peak rating • Generator exciter peak rating • Bus voltage • Starting motor bus • Grid/generator bus • HV, MV, and LV bus • User definable minimum time span

- 279. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 279 Starting Devices Types • Auto-Transformer • Stator Resistor • Stator Reactor • Capacitor at Bus • Capacitor at Motor Terminal • Rotor External Resistor • Rotor External Reactor • Y/D Winding • Partial Wing • Soft Starter • Stator Current Limit – Stator Current Control – Voltage Control – Torque Control

- 280. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 280 Starting Device • Comparison of starting conditions

- 281. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 281 Starting Device – AutoXFMR • C4 and C3 closed initially • C4 opened, C2 is closed with C3 still closed. Finally C3 is open

- 282. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 282 Starting Device – AutoXFMR • Autotransformer starting MCC M Autotransformer starter line Vmcc EX. 50% Tap VMCC 50% tap 5VMCC IST 3IST VM PFST ( with autotransformer) = PFST ( without autotransformer)

- 283. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 283 Starting Device – YD Start • During Y connection Vs = VL / √3 • Phase current Iy = Id / √3 and 3 to 1 reduction in torque

- 284. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 284 Starting Device – Rotor R

- 285. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 285 Starting Device – Stator R • Resistor VMCC 50% tap 5VMCC VM RLR XLR RL XL PFST ( with resistor) = 1-[pu tap setting ]² * [ 1- (PFST without resistor)²] = 1- (0.5)² * [1-(PFST)²]

- 286. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 286 VMCC 50% tap 5VMCC VM RLR XLR RL XL Starting Device Stator X • Reactor PFST ( with reactor) = [pu tap setting ] * PFST (without reactor)

- 287. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 287 Transformer LTC Modeling • LTC operations can be simulated in motor starting studies • Use global or individual Tit and Tot V limit Tit Tot T

- 288. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 288 MOV Modeling I • Represented as an impedance load during operation – Each stage has own impedance based on I, pf, Vr – User specifies duration and load current for each stage • Operation type depends on MOV status – Open statusclosing operation – Close statusopening operation

- 289. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 289 MOV Modeling II • Five stages of operation Opening Closing Acceleration Acceleration No load No load Unseating Travel Travel Seating Stall Stall • Without hammer blow Skip “No Load” period • With a micro switch Skip “Stall” period • Operating stage time extended if Vmtr < Vlimit

- 290. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 290 MOV Closing • With Hammer Blow- MOV Closing

- 291. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 291 MOV Opening • With Hammer Blow- MOV Opening

- 292. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 292 UNSETTING TRAVEL VMTR < V LIMIT STALL ACCL I MOV Voltage Limit • Effect of Voltage Limit Violation Tacc Tpos Travel Tstl

- 293. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Slide 293 TEMA 6

- 294. ©1996-2009 Operation Technology, Inc. – Workshop Notes: Short-Circuit IEC Short-Circuit ANSI Standard