Operation of reciprocating pump

- 1. Operation of Reciprocating Pump FLUID POWER ENGINEERING

- 2. introduction • If mechanical energy is converted into hydraulic energy by taking water inside the cylinder in which piston is reciprocating, which exerts thrust force on the liquid is known as reciprocating pump. • A reciprocating pump is a class of positive- displacement pumps which includes the piston pump, plunger pump and diaphragm pump. • The given pump is single acting single cylinder pump with air vessel. It can be used for less discharge at higher heads. Priming is not required because it is a positive displacement pump. Reciprocating pumps are used in pumping water in hilly areas

- 3. Components of reciprocating pumps • Main parts of reciprocating pump • A cylinder with a piston, piston rod and cranka • Suction pipe • Delivery pipe • Suction pipe • Delivery pipe

- 4. Classification of reciprocating pump • Based on contact of liquid Single acting Double acting • Based on reciprocating member Piston pump Plunger pump Bucket pump • Based on number of cylinder Single cylinder Multi cylinder

- 5. • Discharge through a single acting reciprocating pump. • D=diameter of the cylinder • A=cross section area of the Piston or cylinder • r=radius of the Crank • N=RPM of Crank • L=length of stroke = 2 x r • hs=equals to suction head or height of excess of the cylinder from water surface in sump • hd=delivery head or height of the delivery outlet above the cylinder axis • Discharge of water in one revolution = Area x Length of stroke = A x L • Number of revolution per second =N/60 • Discharge of pump per second Q =Discharge in one second x number of revolution per second = A x L x N/60 = ALN/60 m3/sec

- 6. Double acting reciprocating pump • In case of double-acting pump, the water is acting on both sides of the piston as shown in figure. Thus, we require two suction pipes and two delivery pipes for double-acting pump. • When there is a Suction stroke on one side of the piston, there is at the same time a delivery stroke on the other side of the piston. Thus for one complete revolution of the crank there are two delivery strokes and water is delivered to the pipes by the pump during these two delivery strokes.

- 7. Discharge through double acting reciprocating pump • Discharge = water discharge + water discharge • in forward stroke in reverse stroke = ᴫD2L/4 + ᴫ(D2 – d2) L/4ᴫ = ᴫD2L/4 + ᴫD2L/4 - ᴫd2L/4 = ᴫ (2D2 - d2) L/4 m3/cycle = ᴫ (2D2 - d2) L/4 * N/60 m3/second Q = 2ALN/60 ( NEGLECTING d2 ) Work done by double acting reciprocating pump • Work done/second = weight of water delivered per second * head lifted = ρgQ * (hs + hd) W.D./SECOND = 2ρgALN * (hs + hd) / 60

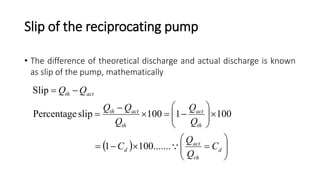

- 8. Slip of the reciprocating pump • The difference of theoretical discharge and actual discharge is known as slip of the pump, mathematically d rh act d th act th actth actth C Q Q C Q Q Q QQ QQ .......1001 1001100slipPercentage Slip

- 9. Indicator Diagram • The pressure variation in the cylinder during a cycle consisting of one revolution of the crank. When represented in a diagram is termed as indicator diagram. • Figure represents an ideal diagram, assuming no other effects are involved except the suction and delivery pressures. • Point 1 represents the condition as the piston has just started moving during the suction stroke.

- 10. Indicator Diagram • 1-2represents the suction stroke and the pressure in the cylinder is the suction pressure below the atmospheric pressure. • The point 3 represents the condition just as the piston has started moving when the pressure increases to the delivery pressure. Along 3- 4 representing the delivery stroke the pressure remains constant. • The area enclosed represents the work done during a crank revolution to some scale 60 ds ds hhgLAN p hhgQp