Operations Management powerpoint present

- 1. M A N A G E M E N OPERASI Dosen Pengasuh: Dr. Ir. Suganda Thalib, MM PROGRAM PASCA SARJANA (S2) IMMI – ADHY NIAGA

- 2. O P E R A T I O N S M A N A G E M E N T Strategy and Analysis Lee J. Krajewski Larry P. Ritzman

- 3. 1. Operations As a Competitive Weapon Strategic Choices 2. Operations Strategy Process 3. Process Management 4. Management of Technology 5. Work-Force Management Quality 6. Total Quality Management 7. Statistical Process Control

- 4. Capacity, Location, and Layout 8. Capacity 9. Location 10. Layout Operating Decisions 11. Supply-Chain Management 12. Forecasting 13. Inventory Management 14. Aggregate Planning 15. Material Requirements Planning 16. Just in Time Systems 17. Scheduling

- 5. OPERATIONS AS A COMPETITIVE WEAPON Chapter 1

- 6. DEFINITION This day, the term OPERATION MANAGEMENT refers to the direction and control of the processes that transform inputs into finished goods and services. The Operations Management System External environment Customer or client participation Operations and processes 1 3 2 4 5 Outputs Goods Services Information performance Inputs : • Workers • Managers • Equipment • Facilities • Materials •Services • Land • Energy

- 7. FIVE CATAGORIES OF DECISIONS TYPES Strategic choices : strategic decision that effect a company’s future direction. Process : processes are fundamental to all activities that produce goods and services. Quality : Quality issues underline all processes and work activities Capacity : The types of decision in this category often require long-term commitments. Operating decisions : Operating decision deal with operating the facility after it has been built.

- 8. BASIC STEPS OF DECISION MAKING Recognize and clearly define the problem Collect the information needed to analyze possible alternatives Choose the most acctractive alternative and implement it

- 9. The Operations Management As a Function TYPES OF ORGANIZATIONS FUNCTIONS SKILL AREAS Manufacturing Construction Transportation Health care Manufacturing Construction Transportation Health care • Accounting • Distributing • Engineering • Operations • Finance • Human resources • Marketing Quantitative methods Organizational behavior General management Information systems Economics International business Business ethics and law 0 • • • • • • • •

- 10. CONTINUUM OF CHARACTERISTICS OF MANUFACTURING AND SERVICE OPERATIONS More like a service organization More like a manufacturing organization Physical, durable product Output can be inventoried Low customer contact Long response time Regional. National or international markets Large facilities Capital intensive Quality easily measured Intangible, perishable produc Output cannot be inventoried High customer contact Short response time Local markets Small facilities Laborl intensive Quality not easily measured

- 11. SIMILARITIES (Manufacturing - Services) Manufacturing do not just offer products, and service organizations do not just offer services. Both types of organizations normally provide a package of goods and services. Customers expect both good services and good food in restaurant, and manufacturing firm also offer many customer services. Despite the fact that service providers can’t inventory their outputs, they must inventory the inputs for their product. As for customer contact, many service operations have little outside customer contact, such as the back-room operations of a bank or baggage handling area at an airport.

- 12. Some Trends That Impact on Operation Management Service sector growth Productivity changes Global competition Competition based on quality, time and technology Environmental, ethical, and work-force diversity issues

- 13. Service Sector Growth : Percentage of Job in the US Service Sector 40 30 20 10 0 1957 1967 1977 1987 1997 Other services Wholesale and retail sales Government Manufacturing, mining, and construction Percentage of work force

- 14. Productivity Changes : US and Worldwide Productivity Growth 0 1 2 3 Percent 1950s 1960s 1970s 1980s 1990s (to date) 2.8 2.8 1.9 1.0 1.0 100 80 60 40 20 0 Percent United State Germany France Japan Britain Whole economy Manufacturing A. Average Annual Growth In Productivity for US Business Sector B. Current Value Added Per Hour Worked by Sector and Country

- 15. GLOBAL COMPETITION Today business accept that to prosper they must view customers, suppliers, facility locations, and competitors in global term.

- 16. Operation Management as an Interfunctional Imperative • Cross-functional coordination • Achieving cross-functional coordination Operation management as a competitive weapon Business and government leader increasingly are recognizing the importance of involving the whole organization in making strategic decisions in order to compete globally

- 18. COMPETITIVE PRIORITIES : Link Between Corporate Strategy and Functional Area Strategy Market analysis • Segmentation • Needs assesment Socioeconomic and business environment Corporate strategy • mission • goals • distinctive competencies Future direction • global strategy • new products / services COMPETITIVE PRIORITIES Operation Marketing • cost • quality Finance • time • flexibility Others Capabilities • current • needed • plans Functional area strategies • finance • marketing • operations

- 19. CORPORATE STRATEGY Defines the business that the company will pursue, new opportunities and threats in the environment, and the growth objectives that it should acheive

- 20. STRATEGIC CHOICES • Mission : A firm’s mission statement answers fundamental question : • What business are in ? Where should we be ten years from now ? • Who are our customers (or clients) • What are our basic beliefs ? • What are the key performance objectives and by which we measure success ? • Environment : The external business environment in which a firm competes changes continually, and an organization needs adapt • Core competencies : are organization’s unique resources and strengths that management considers when formulating strategy. Competencies include the following : • Work force • Facilities • Market and financial know-how • System and strategy

- 21. GLOBAL STRATEGIES May include buying foreign parts or services, combating threats from foreign competitors, or planning ways to enter markets beyond traditional national boundaries STRATEGIC ALLIENCE 1. Collaborative effort 2. Joint venture 3. Licensing of technology

- 22. MARKET ANALYSIS Market Segmentation Needs assessment Identifying groups of customer which enough in common to warrant the design and provision of product or services that the larger group wants and needs. Market segmentation can be formed from: • Demographic factors • Psychological factors • Industry factors Identifying the needs of each segment and assesses how well competitors are addressing those needs Market needs may be grouped as follows : • Product/service needs • Delivery system needs • Volume needs • Other needs

- 23. COMPETITIVE PRIORITIES Eight possible competitive priorities Cost Quality Time Flexibility 1. Low-cost operations 2. High-performance design 3. Consistent quality 4. Fast delivery time 5. On-time delivery 6. Development speed 7. Customization 8. Volume flexibility

- 24. FLOW STRATEGY CORPORATE STRATEGY Future direction Competitive priorities Capabilities • Process decision • Quality decisions • Capacity, location, and layout decision • Operating decision Flow Strategy • Flexible flows • Intermediate flows • Line flows Operation Strategy

- 25. A CONTINUUM OF FLOW STRATEGY Flexible flows Intermediate flows Line flows • Tool and die shop • Health center • General medical practice • Branch office • Print shop • Health clinic • Oil refine • Cafeteria • Assembly plant Jumbled flows Jumbled, but with some dominant flows Linier flows FLOW PATTERN VOLUME Low volumes or one-of-a-kind products or services Moderate volume High volume None None

- 26. FLOW STRATEGY AND COMPETITIVE PRIORITIES Linking Flow Strategy with Competitive Priorities Flow Strategy Flexible Flows Line Flows Tendency for customized products and services, with low volumes High-performance design quality More emphasis on customization and volume flexibility Long delivery times Tendency for standardized products and services, with high volumes Consistent quality More emphasis on low cost Short delivery times

- 28. WHAT IS PROCESS MANAGEMENT A process involves the use of an organization’s resources to provide something of value. Process decision must be made when : - New or substantially modified product or service is being offered - Quality must be improved - Competitive priorities have changed - Demand for a product or service is changing - Current performance is inadequate - Competitors are gaining by using a new process or technology - the cost or availability of inputs has changed

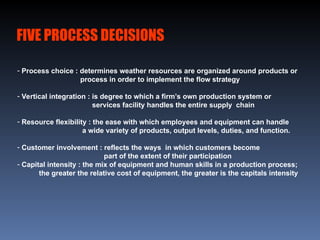

- 29. FIVE PROCESS DECISIONS - Process choice : determines weather resources are organized around products or process in order to implement the flow strategy - Vertical integration : is degree to which a firm’s own production system or services facility handles the entire supply chain - Resource flexibility : the ease with which employees and equipment can handle a wide variety of products, output levels, duties, and function. - Customer involvement : reflects the ways in which customers become part of the extent of their participation - Capital intensity : the mix of equipment and human skills in a production process; the greater the relative cost of equipment, the greater is the capitals intensity

- 30. The influence of flow strategy, customization, and volume on process choice Customization Volume Flexible flows Intermediate flows Line flows Low None High High Low Project process Job process Batch process Line process Continuous process

- 31. RELATIONSHIP BETWEEN PROCESS COST AND PRODUCT VOLUME Units per year (Q) Break-even quality Process 2: Special-purpose equipment Process 1: General-purpose equipment F1 F2 .

- 32. VOLUME AND THE MAJOR PROCESS DECISION Customization Volume Flexible flows Intermediate flows Line flows Low None High High Low Project process Job process Batch process Line process Continuous process

- 34. WHAT ITEMS SHOULD BE AGGREGATED ? Product families Labor Times

- 35. RELATIONSHIP OF PRODUCTION OR STAFFING PLAN (AGGREGATE PLAN TO OTHER PLANS) Business or annual plan Production or staffing plan MSP or Work-force schedule

- 36. MANAGERIAL IMPORTANCE OF AGGREGATE PLANS Managerial inputs Typical objectives Reactive alternatives Aggressive alternatives Planning strategies

- 37. OPERATIONS Current machine capacities Plans for future capacities Work-force capacities Current staffing level MATERIALS Supplier capabilities Storage capacity Materials availability ENGINEERING New products Product design changes Machine standards Aggregate plan DISTRIBUTION & MARKETING Customer needs Demand forecasts Competition behavior ACCOUNTING & FINANCE Cost data Financial condition of firm HUMAN RESOURCES Labor-market conditions Training capacity MANAGERIAL INPUTS FROM FUNCTIONAL AREAS TO AGGREGATE PLANS

- 38. Six objectives usually are considered during development of a production of staffing plan, and conflicts among them may have to be resolved : Minimize cost/maximize profits Maximize customer service Minimize inventory investment Minimize change in production rates Minimize change in work-force levels Maximize utilization of plan and equipment

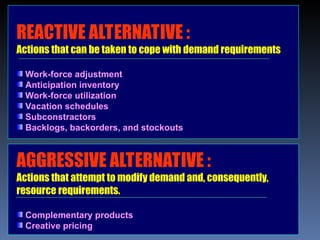

- 39. REACTIVE ALTERNATIVE : Actions that can be taken to cope with demand requirements Work-force adjustment Anticipation inventory Work-force utilization Vacation schedules Subconstractors Backlogs, backorders, and stockouts AGGRESSIVE ALTERNATIVE : Actions that attempt to modify demand and, consequently, resource requirements. Complementary products Creative pricing

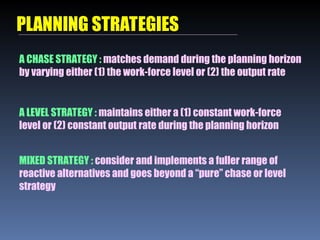

- 40. PLANNING STRATEGIES PLANNING STRATEGIES A CHASE STRATEGY : matches demand during the planning horizon by varying either (1) the work-force level or (2) the output rate A LEVEL STRATEGY : maintains either a (1) constant work-force level or (2) constant output rate during the planning horizon MIXED STRATEGY : consider and implements a fuller range of reactive alternatives and goes beyond a “pure” chase or level strategy

- 41. THE PLANNING PROCESS THE PLANNING PROCESS First step : Determining demand requirements Second step : Identifying alternatives, constraints, and cost Third step : prepare the acceptable plan Final step : implementing and updating the plan

- 42. Determine requirements for planning horizon Move ahead to next planning session Identify alternatives, constrains and cost Prepare prospective plan for planning horizon Is the plan acceptable Implement and update the plan No Yes THE PROCESS FOR PREPARING AGGREGATE PLANS THE PROCESS FOR PREPARING AGGREGATE PLANS

- 44. INPUTS TO MATERIAL INPUTS TO MATERIAL REQUIREMENTS PLANNING REQUIREMENTS PLANNING Bill of materials : a record of all the components of an item, the parent-component relationships, and usage quantities derived from engineering and process design Master production schedule : details how many end items will be produced within specified periods of time Inventory record : the final input to MRP

- 45. Authorized master production schedule Inventory records MATERIAL REQUIREMENTS PLAN INPUTS MATERIAL REQUIREMENTS PLAN INPUTS Other sources of demand Inventory transactions MRP explosion Bill of materials Engineering and process designs Material Requirements plan

- 46. INVENTORY RECORD INVENTORY RECORD Time-phased information contained in the inventory record consists of : Time-phased information contained in the inventory record consists of : Gross requirements : Total demand derived from all parent production plans. Scheduled receipts : order that have been placed but not yet completed Projected on-hand inventory : an estimate of the amount of inventory available each week after gross requirement have been satisfied Planned receipts : Planning for receipt of new orders will keep the projected oh-hand balance from dropping below zero Planned order releases : Indicates when an order for a specified quantity of an item is to be issued

- 47. PLANNING FACTOR PLANNING FACTOR Planning lead time : An estimate of the time between placing and order for an item and receiving it in inventory / The time allowed for receiving a shipment from the supplier after the order has been sent, including the normal time t o place the order. Lot-sizing rules : Determines the timing and size of order quantities. - Fixed Order Quantity (FOQ) - Periodic Order Quantity (POQ) Safety stock

- 48. OUTPUTS FROM MRP OUTPUTS FROM MRP Material Requirement Planning Explosion Action Notices Capacity Report

- 49. MRP OUTPUTS MRP OUTPUTS MRP explosion Action notices Releasing new orders Adjusting due dates Priority report Dispatch lists Supplier schedules Priority report Capacity require- ment planning Finite capacity scheduling Input-output control Routings and time standards Cost and price data Manufacturing resources plan Performance report Material requirement plan

- 50. Bill of Material for the Seat Subassembly Bill of Material for the Seat Subassembly C (1) Seat subassembly H (1) Seat frame J (1) Seat-frame boards I (1) Seat cushion

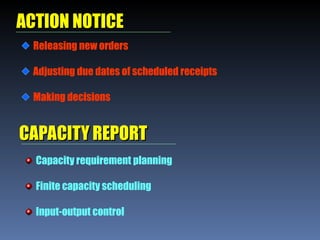

- 51. ACTION NOTICE ACTION NOTICE Releasing new orders Adjusting due dates of scheduled receipts Making decisions CAPACITY REPORT CAPACITY REPORT Capacity requirement planning Finite capacity scheduling Input-output control

- 52. Bill of Resources for Bill of Resources for Treating an Aneurysm Treating an Aneurysm Level 1 Discharge Level 2 Intermediate care Level 3 Postoperative care (Step down) Level 5 Surgery Level 4 Postoperative care (intensive) Level 6 Preoperative care (Angiogram) Level 7 Preoperative care (Testing) Level 6 Preoperative care (Angiogram) Nurse (6 hr) MD (1 hr) Therapy (1 hr) Bed (24 hr) Lab (3 test) Kitchen (1 meal) Pharmachy (10 medicines) B B A A

- 53. RESOURCE PLANNING RESOURCE PLANNING Manufacturing resources planning (MRP II) Resource planning for services Enterprise resource planning IMPLEMENTATION ISSUES IMPLEMENTATION ISSUES Pre requisities Computer support Accurate and realistic input Favorable environments for material requirements planning Number of BOM levels Magnitude of lot sizes Volatility

- 55. SCHEDULING IS IMPORTANT TO : SCHEDULING IS IMPORTANT TO : Accounting : which administers the billing process that is driven by the scheduling of products or services. Finance : which manages the cash flows in the firm which in turn are a function of the effectiveness of product and service scheduling. Human resources : which hires and trains employees needed to support workforce schedules. Marketing : which depends on meeting due dates promised to customers Management information system : which designs the software and databases to support the scheduling process. Operation : which is responsible for effective scheduling of

- 56. TWO BASIC TYPES OF SCHEDULING TWO BASIC TYPES OF SCHEDULING Work-force scheduling : which determines when employees works. Operation scheduling : which assigns jobs to machines or worker to jobs.

- 57. SCHEDULING IN MANUFACTURING SCHEDULING IN MANUFACTURING Operation schedules : short-term plans designed to implement the master production schedule. Operation scheduling focus on how best to use existing capacity, taking into account technical production constraints. Gantt Charts : a visual tool for sequencing work on machines and monitoring its progress. The chart takes two basic forms : the job or activity chart and the machine chart. Performance Measures

- 58. DIAGRAM OF A MANUFACTURING PROCESS DIAGRAM OF A MANUFACTURING PROCESS Raw Material Raw Material Shipping Department Shipping Department Workstation Workstation Batch of parts Batch of parts

- 59. Job flow time : the amount of shop time for the job Job flow time = Time of completion - Time job was available for first processing operation Makespan : the total amount of time required to complete a group jobs. Makespan = Time of completion of last job – Starting time of first job Past due : amount of time by which a job missed its due date or the percentage of total jobs processed over some period of time that missed their due dates. work-in-process inventory : Any job in waiting line, moving from one operation to the next, being delayed for some reason, being processed, or residing in component or subassembly inventories. Total inventory = the sum scheduled receipts and on-hand inventories . Utilization = the percentage of work time productively spent by a machine or worker. Productive work time Utilization = Total work time available PERFORMANCE MEASURES :

- 60. JOB SHOP DISPATCHING Critical ratio : calculated by dividing the time remaining to a job’s due date by the total shop time remaining for the job. Earliest due date : the job with earliest due date is scheduled next. First come, first served : the job that arrived at the workstation first has the highest priority under first come, first served. Shortest processing time : the job requiring the shortest processing time at the workstation is processed nest. Slack per remaining operations : the difference between the time remaining to a job’s due date and the total shop time remaining, including that of the operation being scheduled.

- 61. SEQUENCING OPERATIONS FOR ONE MACHINE Single-Dimension Rules Multiple Dimension Rules Multiple-Workstation Scheduling Sequencing Operations for Two-Station Flow Shop Labor-Limited Environments Theory of constraints : - Identify the system bottleneck - Exploit the bottleneck - Subordinate all other decision to step - elevate the bottleneck - Don’t let inertia set in

- 62. SCHEDULING IN SERVICES Scheduling Customer Demand - Appointments - Reservations - Backlogs Scheduling the Work Force - Constraints - Developing a work-force schedule - Computerized work force scheduling systems