Purchase english

- 1. The Essentials - Purchase HASH MANAGEMENT SERVICES LLP CHENNAI PH: 91766 13965

- 2. Overview ‘The Essentials’ series from Business Sense is an initiative to empower the students(freshers) and professionals in performing more efficiently and effectively in the organization This document is a part of the “Certified Manufacturing Professional” course offered by Business Sense This course is aimed at bridging the gap between the institutions and the industry by providing the fundamentals of manufacturing management which are not offered by any of our institutions/curriculum This course would immensely benefit students and professionals who are joining manufacturing organizations For more details, please visit www.businessense.in At Business Sense, we help clients through consulting engagements focusing on improving their Operations through Lean Manufacturing Implementation covering 5S, SMED, Kaizen and other tools. We also serve clients on Preparation of Detailed Project Reports, Market Assessments, and Supply Chain Re-engineering. You can subscribe to our bi-weekly newsletter here. Follow us: Copyright of Hash Management Services LLP www.businessense.in

- 3. Contents Section 1 – Introduction and Basic Processes Section 2 – Materials Classification Techniques Section 3 – Ordering Techniques Section 4 – Vendor Management Section 5 – MIS Reports and Analyses Points Copyright of Hash Management Services LLP www.businessense.in

- 4. Introduction to Purchase Function Purchasing refers to a business or organization attempting for acquiring goods or services to accomplish the goals of the enterprise Purchasing role in any organization is considered to be important as it handle raw materials & Sub-assemblies which have significant cost impact on material manufactured. Purchasing is key element of Supply chain management of any organization more ever in recent times as sourcing are increasingly done from many countries. Companies with robust purchasing department and experts give better business results than others. Purchase Supplier / Company Function Vendor Copyright of Hash Management Services LLP www.businessense.in

- 5. Organization Structure This is a standard organization structure for Purchase Function Purchase Manager reports to the CEO of CEO the company There would be a few Purchase Executives / Assistants reporting to the Purchase Purchase Manager Manager Each Purchase executive would typically Purchase Purchase Purchase focus on a single raw material category Executive / Executive / Executive / Assistant Assistant Assistant We have explained a typical functional hierarchy. It may vary according to each organization Copyright of Hash Management Services LLP www.businessense.in

- 6. Responsibilities of an Engineer in the Purchase Function Acquire quality goods and services in a professional, timely and cost effective manner Help develop and maintain a supplier/vendor community capable of supporting the organization’s needs with emphasis on superior service quality and cost effectiveness Classification of all the materials (including packing materials) as A, B and C Class items (methodology described later in the presentation) – to be done jointly with Stores function Tracking of the lead time of all A & B Class items and make necessary changes in the purchase process Maintaining Nil Stock-Out situation all times Scheduled Purchase for all regular/fast moving A Class items Re-Order level based ordering for all A&B Class items Two Bin System / Min-Max for all C Class items All Purchases through formal PO only – no telephone based/other means of ordering Creation / Preparation of the Management Information Systems (MIS) that enable better decision making processes for the present and the future, and present it to the Senior Management Updation of records daily including Pending Order Status Copyright of Hash Management Services LLP www.businessense.in

- 7. Process Flow - 1 Stores Assistant/Executive sends a Purchase Indent (PI) to the Purchase Executive depending on the status of the material available in the stores. The quantity is based on the Production Planning / requirements discussed with the other functions. Pending Orders, Items in transit etc. Each PI should have a unique no which would be mentioned in the PO later Copyright of Hash Management Services LLP www.businessense.in

- 8. Process Flow - 2 Purchase Executive then collects the Purchase Indents and creates a Purchase Orders (PO) and sends them to Purchase Manager for approval. The POs’ can be supplier-wise / item-wise. Each PO should have a unique PO number which should be mentioned in the PO, tracking sheet/systems, should be mentioned by the supplier while sending the Invoice back to the company Copyright of Hash Management Services LLP www.businessense.in

- 9. Process Flow - 3 Purchase Manager approves the POs’ within 1 day (can be fixed by the senior management) and send back to the Purchase Executive Copyright of Hash Management Services LLP www.businessense.in

- 10. Process Flow - 4 Approved POs’ should be sent to the Suppliers on the same day ( hard copy / email) Once the POs’ are sent, the suppliers should be followed-up for the deliveries. Lead time based tracking should be done and once the lead time is crossed it should be informed to the Purchase Manager Copyright of Hash Management Services LLP www.businessense.in

- 11. Process Flow - 5 Supplier sends the materials to the company with the Invoice and Delivery Challan (DC) Once the materials are received, the Stores Assistant / Executive checks for the quality and quantity and prepares a Goods Receipt Note (GRN) and updates the stock on the same day Copyright of Hash Management Services LLP www.businessense.in

- 12. Snapshot of Purchase Function Purchase Process Purchase Manager Purchase Approved Order Purchase For Approval Order Purchase Purchase Stores Indent Order Assistant Purchase Sent to Suppliers Suppliers Executive Goods Receipt Note - Stores Assistant Invoice, Delivery Challan Warehouse Shipments Copyright of Hash Management Services LLP www.businessense.in

- 13. Contents Section 1 – Introduction and Basic Processes Section 2 – Materials Classification Techniques Section 3 – Ordering Techniques Section 4 – Vendor Management Section 5 – MIS Reports and Analyses Points Copyright of Hash Management Services LLP www.businessense.in

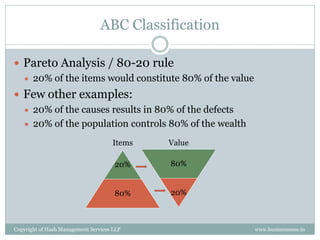

- 14. ABC Classification Pareto Analysis / 80-20 rule 20% of the items would constitute 80% of the value Few other examples: 20% of the causes results in 80% of the defects 20% of the population controls 80% of the wealth Items Value 20% 80% 80% 20% Copyright of Hash Management Services LLP www.businessense.in

- 15. ABC Classification In any organization, the raw materials form about 60~65% of the Cost of Goods Sold (COGS). COGS: All Raw Materials – 60~65% Labor Cost – 7~8% Power & utiities – 8~10% . . . _______________________ Total – 100% Copyright of Hash Management Services LLP www.businessense.in

- 16. ABC Classification While analyzing the raw materials it would be clear that the top 20% of the items would constitute about 80% of the purchase value. Next 30~40% items would constitute about 15% of the purchase value. Remaining 50% of the items constitute 5% of the purchase value. Few Items = More consumption in value A Category B Category More Items = Low consumption in value C Category Methodology of analyzing ABC items, and Lead time are explained in the “Certified Manufacturing Professional” course. To access login to www.businessense.in Copyright of Hash Management Services LLP www.businessense.in

- 17. Contents Section 1 – Introduction and Basic Processes Section 2 – Materials Classification Techniques Section 3 – Ordering Techniques Section 4 – Vendor Management Section 5 – MIS Reports and Analyses Points Copyright of Hash Management Services LLP www.businessense.in

- 18. Ordering Techniques Category Characteristics Ordering Techniques Reason For items whose Scheduled Shipments / Standard consumption is regular Order Quantity (SOQ) through-out the season Very High Value. Need to A monitor continuously For items whose Re-Order level consumption do not follow a pattern Moderate Value – Moderate Order based on the Re-Order B Impact on the Inventory Re-Order level level Holding Low Value – No major impact Do not focus more on the C C on the Inventory Holding MinMax / Two Bin System Category items Cost Methodology of calculating ROL, Scheduled Shipments, MinMax quantities are explained in the “Certified Manufacturing Professional” course.To access login to www.businessense.in Copyright of Hash Management Services LLP www.businessense.in

- 19. Contents Section 1 – Introduction and Basic Processes Section 2 – Materials Classification Techniques Section 3 – Ordering Techniques Section 4 – Vendor Management Section 5 – MIS Reports and Analyses Points Copyright of Hash Management Services LLP www.businessense.in

- 20. Vendor Management Any addition/modification of the vendor should be carried out through proper Vendor Evaluation Report Following are the parameters that have to be considered in a Vendor Evaluation Report S.No Parameters Weightage in % 1 Quality 30 2 Adherence to Delivery 20 3 Price 15 4 Average Lead time 15 5 Credit Period 10 6 Support during emergencies 10 Please note that the weightages are based on general management principles. They can be modified according to the industry / companies Copyright of Hash Management Services LLP www.businessense.in

- 21. Vendor Master Sheet A Vendor Master Sheet should be maintained in the purchase function. Following are the details to be recorded: S.No Details to be recorded 1 Item Code 2 Item Description 3 Vendor Code 4 Vendor Name 5 Address 6 Contact Person 7 Phone No 8 Email Id 9 Vendor rating (based on the weightages) Copyright of Hash Management Services LLP www.businessense.in

- 22. End of Free Content Please visit our website www.businessense.in to access the full course – “Certified Manufacturing Professional” Our website also contains list of ready-to-use templates and report formats containing Charts and pivot tables. Templates and report formats are available for Purchase, Stores, Production, Quality, Maintenance and HR functions These templates come in excel /word and can be downloaded and used right away At Business Sense, we help clients through consulting engagements focusing on improving their Operations through Lean Manufacturing Implementation covering 5S, SMED, Kaizen and other tools. We also serve clients on Preparation of Detailed Project Reports, Market Assessments, and Supply Chain Re-engineering. You can subscribe to our bi-weekly newsletter here. Follow us: Copyright of Hash Management Services LLP www.businessense.in