Unit6 Computer Numerical Control

- 1. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/1 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c UNIT 6 COMPUTER NUMERICAL CONTROL OBJECTIVES General Objective :To understand the concept and principles of computer numerical control (CNC) system. Specific Objectives : At the end of the unit you will be able to : Ø Understand the main components of the CNC system, Ø Understand the point-to-point system (positioning), Ø Understand the contouring system (continuous system), and Ø Write a simple CNC milling program. .

- 2. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/2 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c INPUT 6.0 INTRODUCTION Computer numerical control is a system in which a control microcomputer is an integral part of a machine or a piece of equipment (onboard computer). The part programmes can be prepared at a remote site by programmer, and it may incorporate information obtained from drafting software packages and from machining simulations, in order to ensure that the part programme is bug free. The machine operator can, however, easily and manually programme onboard computers. The operator can be modify the programs directly, prepare programme for different parts, and store the programmes. Because of the availability of small computers having a large memory, microprocessor(s), and programme-editing capabilities, CNC systems are widely used today. The availability of low-cost programmable controllers also played a major role in the successful implementation of CNC in manufacturing plants. Numerical Control is a system where machine action is created from the insertion of Numeric Data. The Numeric Data is, in the beginning, written words in an easily understood code of letters and numbers (alphanumeric characters) known as a programme, which in turn is converted by the machine control unit (MCU) into the electrical signals used to control the machine movements.

- 3. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/3 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c The relationship between the words "Numerical" and "Control" is shown below. NUMERICAL CONTROL An instructional expression, To control such machine in a language of numbers, actions as: which represents a series of Directing Altering commands for specific Commanding Timing Prescribing Ceasing machine tool movements Sequencing Guiding Initiating Two important points should be made about N.C. First, the actual N.C. machine tool can do nothing more than it was capable of doing before a control unit was joined to it. There are now new metal removing principles involved. N.C. machines position and drive the cutting tools, but the same milling cutters, drills, taps, feeds, and other tools still perform the cutting operations. Cutting speeds, feeds, and tooling principles must still be adhered to. Given this knowledge, what is the real advantage of numerical control? Primarily, the idle time or time to move into position for new cuts is limited only by the machine's capacity to respond. Because the machine receives commands from the machine control unit (MCU), it responds without hesitation. The actual utilisation rate or chip making rate is therefore much higher than on a manually operated machine. The second point is that numerical control machines can initiate nothing on their own. The machine accepts and responds to commands from the control unit. Even the control unit cannot think, judge, or reason. Without some input medium, e.g., punched tape or direct computer link, the machine and control

- 4. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/4 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c unit will do nothing. The N.C. Machine will perform only when the N.C. tape is prepared and loaded and cycle start is initiated. 6.1. NC OPERATION CNC stands for Computer Numerical Control. An N.C. system in which a dedicated stored program computer is used to perform basic control functions. The functions of a CNC Controller are: 1. To read and store programme information. 2. To interpret the information in a logical command sequence. 3. To control the motion of the machines mechanical members. 4. To monitor the status of the machine. The interpretation of programme commands by a machine control unit and its conversion of those commands into machine motion is complex. The basic elements and operation of a typical NC machine are shown in Fig. 6.1. The functional elements in numerical control and the components involved follow: a. Data input: The numerical information is read and stored in the tape reader or in computer memory b. Data processing: The programmes are read into the machine control unit for processing. c. Data output: This is information is translated into commands (typically pulsed commands) to the servomotor (Fig. 6.2 and 6.3). The servomotor then moves the table (on which the work piece is mounted) to specific positions, through linear or rotary movements, by means of stepping motors, leadscrews, and other similar devices.

- 5. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/5 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c Computer: Input command, Processing, Output command Limit switches Position feedback Drive signal Figure 6.1. A schematic illustration of the major component of a computer numerical control machine tool Work table Pulse train Stepping motor Gear Lead screw Figure 6.2. An open-loop control system for a numerical-control machine

- 6. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/6 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c Work table Input Dc Comparator DAC servomotor Gear Feedback signal Lead screw Position sensor Figure 6.3. A closed-loop control system for a numerical-control machine 6.2. INDUSTRIAL APPLICATION 6.2.1. Metal Machining Lathes of all types Milling Machines of all types Drilling Machines Jig borers Electric Discharge Machining (including wire cut machines) Laser cutting machines Machining centres Turning centres All types of grinding machines Gear cutting machines 6.2.2. Metal Forming Punching and nibbling Guillotines Flame cut and profiling Folding

- 7. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/7 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c Pipe bending Metal spinning 6.2.3. Finishing Plating Painting 6.2.4. Assembly Joining - Pick and place robots, spot and seam welding machines and robots, riveting, looming of wires and assembly of components into printed circuit boards. 6.3. CNC AXIS CONVENTIONS CNC axis classification follows the three-dimensional Cartesian coordinate system and is established in BS 3635: 1972: Part 1. Fig. 5.3 shows the tree primary axes and the associated rotational axes. Most machines have two or three slide ways placed at right angles to one another. On CNC machines each slide is fitted with a control system, and is identified with either the letter X, Y or Z. Conventions have been adopted as to the naming of each axis. The axis of the main spindle, whether it is the axis of the tool spindle or the axis about which the work piece rotates is called the Z axis. The X axis is the motion of the largest travel of the primary movement (in case there is more than one).

- 8. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/8 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c The Y axis then makes the third motion and is the shorter primary movement. In addition to these primary linear axes, there is provision for Rotary axes. They are designated A, B and C, with A rotary about the X axis, B rotary about the Y axis, and C rotary about the Z axis. It is often required to command a motion parallel to X, Y or Z axes within the realm of a secondary motion, or a tertiary motion within special automatic cycles such as describing the amount of finish allowance on a turned part, or to describe the distance of advancement of a drill during a drilling cycle etc. etc. Table 6.1. NC axes Linear Axes X Y Z Rotary Axes A B C Secondary Linear U V W Interpolation I J K Tertiary motion codes differ considerably, but the address characters variously used are P, Q, R, D, L, E, and H. The z-axis is parallel to the main spindle of the machine. It will be horizontal on a lathe or horizontal machining centre and vertical on a vertical machining centre. The x-axis is always horizontal and at 90o to z. The y-axis is at right angles to both the x and z axes.

- 9. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/9 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c spindle rotation table z x y Figure 6.3. CNC axes 6.4. NC MACHINE SUB-UNIT We have already seen the many and varied applications of numerical control to the manufacturing and other industries, now we will look at the methods of controlling machines. There are three sub units to study: The machine tool itself. The control unit. The control system.

- 10. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/10 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c 6.4.1. The Machine Tool A machine tool is a device designed to cut away surplus material and leave a component of the required shape and size. To do this a machine tool must be capable of: - Holding the work piece securely - Holding the cutting tool securely and driving it with suitable power. - Moving the tool and work piece relative to one another precisely enough to achieve accuracy of size and surface finish. In addition, provision must be made for altering the spindle speed and feed rates, tool changing, supply of coolant etc. On a conventional machine an operator controls these functions and sets or alters them when he considers it necessary, the decision resulting from his training, skill and experience. Obviously, the machine settings may differ between operators as will the time taken to read scales, set positions, change tools, alter speeds and feeds, engage drives and set up the work piece etc. CNC Automatic Control can be applied to these functions and so result in consistent and reduced machining times through optimised cutting data, fast accurate positioning between cuts and fast automatic tool changing. 6.4.2. The Control Unit The CNC Machine Control Unit (MCU) has to read and decode the part programme, and to provide the decoded instructions to the control loops of the machine axes of motion, and to control the machine tool operations.

- 11. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/11 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c The main grouping of parts of a control could be considered to be: The Control Panel. The Tape Reader, The Processors The first part of the control panel is the human interface that allows various modes of machine or control operation to be initiated, from switching on and homing, to programme loading and editing, to setting work positions and tool offsets, manually controlled movements and commencing the automatic cycling of a programme. Information about machine status and condition is available to the operator via VDU screens, gauges, meters, indicator lights and readouts. The tape reader is the device used to transfer the programme information contained on a programme tape into the control unit. Most tape readers are of the photo-electric type which offers high speed reading with reliability and accuracy providing the tape is in good condition and the reader is kept clean and free of paper dust particles. The processors within a control are the electronic circuits that permit conversion of part programme data into machine motions and they may be classified into two main sections. The data processing unit and the axis control processor. The function of the data processor is to decode the commands of the part program, process it and provide data to the axis control processor which then operates the slide drives and receives feedback signals on the actual position and velocity of each axis.

- 12. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/12 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c The Data Processing Unit includes the following functions: i. The input device, such a tape reader. ii. Reading circuits and parity checking logic. iii. Decoding circuits for distributing data to the controlled axes iv. An interpolator to supply velocity commands to the axes, either singly or in combination. The axis control processor consists of the following circuits: i. Position control loops for each and all axes. ii. Velocity control loops. iii. Deceleration and backlash take up circuits. An MCU is adaptable to virtually any machine, the differing control motions and codes being a result of the way the control has been programmed. This permanent resident program is known as an executive programme and resides in the read only memory (ROM) of the control, whereas the N.C. programme resides in the Random Access Memory (RAM). RAM allows external access and alteration if necessary, while ROM is programmed by the manufacturer and cannot be accessed through the control keyboard. 6.4.3. Control System There are two types of control systems used on NC machines. The point-to-point system and the continuous-path system. Point-to-point systems are not so common these days, but they operate only in straight lines, which are suitable for positioning moves on a drilling machine or limited use on a lathe or milling machine, where at best 45% cuts are possible with two axes running continuous path controls allow angular

- 13. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/13 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c path and radius motion because the control interpolator has the ability to move the axis drive motors at varying velocities. The point-to-point controls were NC controls, while the continuous path controls could be NC or CNC controls. NOTE: NC is a general term used for Numerical Control and is also a term used to describe controls that run directly off tape. CNC is a specific term for Computer Numerical Control. CNC Machines are all NC machines, but NC controlled machines are not CNC machines. 6.5. PROGRAM INPUT Programmes can be produced and entered (loaded) by any of the following methods where available. a. Punched Tape b. Computer c. Direct Input 6.5.1. .Punched Tape Punched tapes may be made of paper or plastic (Mylar) and have a standard width of one inch (25.4mm) for the eight track (8 bit) format used in numerical control. A tape punch unit is connected to a teletype or similar keyboard and produces a punched tape during typing of the program. Alternatively, a punch unit can be connected to a personal computer (P.C.) and the completed programme punched. The holes punched in the tape form

- 14. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/14 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c certain patterns and the pattern represents a value when read by the tape reader on the MCU. The pattern is a code in itself, and complies to a standard, either E.I.A. ( Electronics Industries Association ) which uses an odd number of holes or I.S.O. ( International Standards Organization ) which uses an even number of holes for each character. The I.S.O. code is most commonly used in Australia. The E.I.A. code is known as an odd parity system, and the I.S.O. code as an even parity system. One of the tracks of each is assigned as a parity track and a hole is sometimes punched there automatically to maintain the parity. The purpose of parity is to check during tape reading for errors caused by unpunched holes, dirt or oil spots etc. 6.5.2. Computers Personal computers can be used to type the programme in its entirety while being visible on the screen, so mistakes can easily be spotted and corrected before the programme is loaded into the machine. The programme can be down loaded to the machine via a connecting link (interface cable) or via punched tape if a punch unit is connected to a computer. 6.5.3. Direct Input Programming at the machine may eliminate the need for tape punching equipment and computers, but the machine is usually non- productive during this time. Programming can be done by several methods, such as ;

- 15. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/15 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c - by typing the program directly into the memory of the M.C.U. through the edit function. - programmes produced in this way can include all functions available, are stored in the machine ready for use at any time and can be output to a punch unit or computer for external storage. 6.5.4. By Manual Data Input (M.D.I.) M.D.I. may not allow all programming functions to operate, the programme can only be used once, and as it is not stored in the main memory cannot be output to an external device. Additionally, some controls allow only one line (block) of programme to be entered and executed at a time. 6.5.5. Interactive Programming. Some controls allow programming by a method that may be simpler and speedier than conventional N.C. program language. These methods usually take up considerable memory space and so fewer programmes could be stored in the M.C.U. than if they were prepared by N.C. language. Most of the controls allow for external storage of these programs providing the necessary devices are at hand. Interactive programming can also be known as "conversational", "symbolic", "blueprint","IGF" etc.

- 16. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/16 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c 6.5.6. . External Devices. A programme can be loaded directly from a P.C. as described, or from other specialised units that have been designed as a portable device for loading, transferring or storing N.C. programs. The devices may store the information on floppy discs, hard discs, magnetic tape, or through solid state circuitry. Those with discs or magnetic tape would be no larger than a briefcase or perhaps a tissue box, down to pocket calculator size for solid state devices. NOTE: Where punched tape was once the only practical way for most programmers to transfer (or load) their programs into the controls, it is presently being overtaken by personal computers connected directly via interface cable. Other popular and convenient methods are simply through the edit mode or by interactive (conversational) programming. Companies specialising in complex die work probably use DNC more often now. Inputting through M.D.I. mode is common providing the restrictions noted are adhered to. 6.6. NC PROGRAMMING 6.6.1. Job Planning 1. Sketch the part. Add incremental or absolute dimensions. 2. Ascertain fixturing. Select fixtures which have minimal projections above the part. 3. Identify a set-up point. Locate the set-up point near: 1. A corner of the part 2. A spot above the fixture

- 17. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/17 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c Consider space requirements for: 1. Part loading and unloading 2. Tool change. 4. Plan operation sequence Mark sequence pattern of sketch. Test program data for accuracy. 5. Record necessary data for each movement of the table and tool on the program sheet. 6. Record instructions for Identify, specific: the machine operator. 1. Tools needed. 2. Speed and feed data 3. Tool change points 4. Console switch setting 6.6.2. Incremental The word "incremental" may be defined as a dimension or a movement with respect to the preceding point in a prescribed sequence of points. Each positioning move is described quantitatively in distance and in direction from a previous point rather than from a fixed zero reference point.

- 18. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/18 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c In incremental mode all moves are with respect to the last position reached. N10 G91 Y N15 G01 X10.Y10.F300. N20 Y10. N25 X20. 40 N30 X10.Y20. 30 N35 X20-Y-30. 20 N40 X-10.Y-10. 10 N45 X-50. X N50 M02 10 20 30 40 50 60 6.6.3. Absolute The data in the absolute system describes the next location always in terms of its relationship to the fixed zero point. The zero point when used as a programme datum is known as the programme origin. The G90 code sets the control up in absolute mode. All moves are performed with respect to the axes zero.

- 19. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/19 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c N10 G90 Y N15 G01X10.Y10.F300. N20 Y20. N25 X30. 40 N30 X40.Y40. 30 20 N35 X60.Y10. N40 X50.Y0. 10 N45 X0. 10 20 30 40 50 60 N50 M02 6.6.4. Linear Interpolation Under this command the machine tool will move in a straight line at a defined feed rate. Combined axis motions (angled moves) will be executed at the programming feed rate as the control will reduce the velocity of both axes accordingly. E.g. G01 X200. F250. G01 Move in a straight line X200. A distance of 20O.mm F250. At a feed rate of 250.mm/min. NOTE: If a new line with G01 is listed again somewhere below, the F250 does not have to be written again. This is called modal.

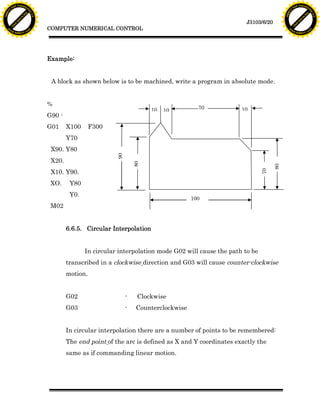

- 20. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/20 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c Example: A block as shown below is to be machined, write a program in absolute mode. % 10 70 10 10 G90 - G01 X100 F300 Y70 X90. Y80 90 X20. 80 80 X10. Y90. 70 XO. Y80 Y0. 100 M02 6.6.5. Circular Interpolation In circular interpolation mode G02 will cause the path to be transcribed in a clockwise direction and G03 will cause counter-clockwise motion. G02 - Clockwise G03 - Counterclockwise In circular interpolation there are a number of points to be remembered: The end point of the arc is defined as X and Y coordinates exactly the same as if commanding linear motion.

- 21. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/21 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c The centre of the arc is defined with respect to the start point in the I and J words as an "increment" from this point. For G02 and G03 to function the feed rate "F." must be specified. Example: N5% N10 G90 N15 G01 Y110. F200. N20 G02 X20. I10. N25 G03 X30. Y100. I10. 110 N30 G01 X90. All radius – R10 N35 G02 X100. Y90. J-10. N40 G01 Y10, N45 G02 X90. Y0. I-10. N50 G01 X0. 100 N55 M02 6.7. PROGRAM DEFINITION To enable the machine to operate automatically it is necessary to put into its memory a programme or set of instructions to carry out the required operation. a) Programme. A programme is a series of instructions to the machine, set out in sequence to -produce a complete machining operation. A programme is made up of a series of blocks.

- 22. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/22 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c b) Block.- A block or programme line is a set of instructions to the machine that are carried out simultaneously. A block is made up of one or more Words and is terminated by an End of Block which is the Line Feed Character. c) Word. A word is a specific instruction to the machine that will affect a particular machine function. Every word consists of a Letter Code and a Numerical value. Examples of Dimensional Words: X100. Y2.345 F0.25 Examples of Non-Dimensional Words: N25 G90 M03 S1200 Dimension words can be written in various ways, depending on the control. Let's take the examples X100. Y2.345 some older controls cannot accept decimal points, so both dimensional words would be written X100000 Y2345, with Y showing all decimal places. With these controls, if the X word was written as X100, it would be interpreted as one-tenth of a millimeter, not one hundred millimeters. If a control accepts decimal points, then ALL dimensional words should have a decimal point. On any control, non-dimensional must NOT have a decimal point. The method of writing words beginning with a letter is known as word address format and is now almost universally used.

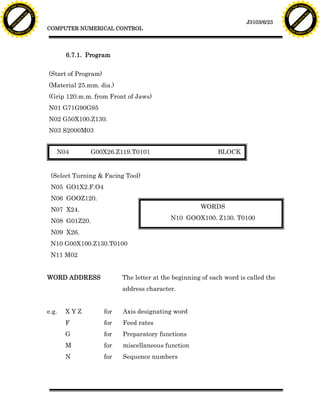

- 23. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/23 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c 6.7.1. Program (Start of Program) (Material 25.mm. dia.) (Grip 120.m.m. from Front of Jaws) N01 G71G90G95 N02 G50X100.Z130. N03 S2000M03 N04 G00X26.Z119.T0101 BLOCK (Select Turning & Facing Tool) N05 GO1X2.F.O4 N06 GOOZ120. N07 X24. WORDS N08 G01Z20. N10 GOOX100. Z130. T0100 N09 X26. N10 G00X100.Z130.T0100 N11 M02 WORD ADDRESS The letter at the beginning of each word is called the address character. e.g. XYZ for Axis designating word F for Feed rates G for Preparatory functions M for miscellaneous function N for Sequence numbers

- 24. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/24 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c CNC mills, drills and machining centers are all equipped with cycles to perform drilling, reaming, counter boring, boring and tapping operations. Some others have pocketing cycles, slot cutting cycles, hole pattern cycles etc, all of which are designed to save programming time and effort. CNC lathes usually have cycles to cover drilling, grooving/parting, screw cutting, repetitive cut (automatic roughing) operations and others. Each cycle has its own G code to control the sequence of motions and an accompanying set of words to define the parameters of those motions. These words have addresses such as: R,P,Q,D,E,I,K,H,B etc. 6.7.2. Program Preparation CNC programmes can be prepared manually, where the programmer usually roughs the programme out on paper, then produces it via a keyboard device of the type detailed below, or by assisted preparation in which a computer plays a predominant role -such as when CAD/CAM packages have been installed for design and programming. The programmer must posses knowledge and skills in planning machining sequences, fixturing, cutting data, cutting tools, calculations, as well as being familiar with the machines he is programming. To implement these skills to best effect a programmer should be prepared to observe critically his programs in use and modify them as necessary in order to gain maximum machine utilization. 6.7.3. Operation of program Before a machine can set into automatic motion a program must be checked for errors. A simple typing mistake - an incorrect code, a minus sign instead of a zero, the exclusion of a decimal etc, could cause and expensive

- 25. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/25 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c machine crash. Anyone who considers their programmes to be without error and not in need of careful and conscientious trialing has an attitude problem and is placing expensive machinery and operators safety at risk. There may be many ways in which a programme can be checked for errors, but a programme can only be proved 100% by running the machine and producing a part. Error checking can be performed in a variety of ways: Verification: Read through the print-out (NOT the handwritten manuscript) carefully - sometimes mistakes can be seen easily. Trialing: This involves the execution of the programme without actually cutting the part and may be carried out in several ways depending on the type of machine, or control, or even the philosophy of the person in charge. Adhere to the later unless you can put up good reasons for alteration. Trialing usually consists of running the machinewith the single block switch active, that is, each block will only be executed by pressing cycle start, in conjunction with the programme being displayed on the screen. Quite often the dry run mode is switched on to hasten Proceedings. 'Dry Run' results in all machine motion being executed at a preset rate, usually in the region of 50% to 80% of the rapid traverse capability of the machine. The actual axis velocity can be overridden from 0% to 100%. The disadvantage of dry running a programme is that feed rates will be masked, and attention must be paid to determining the actual programmed feed rate for each block. This may be displayed on the screen.

- 26. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/26 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c Every movement the machine makes during programme trialing should be expected and accountable to the programmer, if not, those motions should be checked for viability, and if necessary, a more thorough understanding of the machine operation should be sought. Editing: Wherever errors are found, they should be corrected and rechecked, be it on the machine or at the programming station. Whenever a programme is edited on the machine, a note should be made on the print-out so the master or original programme can also be corrected. A better method is to punch out a programme from the control after successfully producing a component. 6.8. TYPES OF CONTROL SYSTEM There are two basic types of control systems in numerical control: point- to-point and contouring. a. In a point-to-point system, also called positioning, each axis of the machine is driven separately by lead screws and, depending on the type of operation, at different velocities. The machine moves initially at maximum velocity in order to reduce non-productive time, but decelerates as the tool approaches its numerically defined position. Thus, in an operation such as drilling (or punching a hole), the positioning and cutting take place sequentially (Fig. 5.4).

- 27. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/27 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c After the hole is drilled or punched, the tool retracts upward and moves rapidly to another position, and the operation is repeated. The path followed from one position to another is important in only one respect. It must be chosen to minimize the time of travel, for better efficiency. Point-to-point systems are used mainly in drilling, punching, and straight milling operations. 15 10 45 C.P 15 (0,0) 10 1 2 4 3 45 Incremental (G90) Absolute (G91) Position Coordinate Coordinate Position Coordinate Coordinate (X) (Y) (X) (Y) C.P. -15 15 C.P. -15 15 Point 1 10 -10 Point 1 25 -25 Point 2 55 -10 Point 2 45 0 Point 3 55 -55 Point 3 0 -45 Point 4 10 -55 Point 4 -45 0 Figure 5.4. Point-to point system

- 28. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/28 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c b. In a contouring system (also known as a continuous path system), the positioning and the operations are both performed along controlled paths but at different velocities. Because the tool acts as it travels along a prescribed path (Fig. 5.5), accurate control and synchronization of velocities and movements are important. The contouring system is typically used on lathes, milling machines, grinders, welding machinery, and machining centres. Cutter Machined radius surface Cutter path Work piece Figure 5.5. Continuous path by a milling cutter 6.9. PROGRAMMING CODES A number of standard codes are used to reduce the amount of programming effort needed to command commonly used machining operations, instructions and conditions. These are commonly known as: G codes – call up machining commands M codes – call up machine control activities T codes – call up tool selection F codes – call up feed rates S codes – call

- 29. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/29 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c - modal codes remain active after being entered, unless they are cancelled by another G code; and - non-modal codes are only active in the programme block in which they appear. 6.9.1. G codes (preparatory codes) The majority of manufacturers follow the same practice in designation of codes, but their detailed implementation mav differ. Sample G codes GOO Rapid movement for position GOI Linear interpolation used for straight-line feed G02 Circular interpolation, clockwise G03 Circular interpolartion, counterclockwise G04 Dwell, a programmed stop to the tool movement G17 Circular interpolation xy plane G18 Circular interpolation xz plane G19 Circular interpolation yz plane G20 Inch units G21 Millimetre units G28 Return to home position G29 Return from home position G31 Reverses programmed direction of x axis G32 Reverses programmed direction of y axis G41 Tool radius compensation left G42 Tool radius compensation right G43 Tool length compensation-positive direction G44 Tool length compensation-negative direction

- 30. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/30 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c G70 Imperial unit G71 Metric units G80 Cancel canned cycle G81 Drilling cycle G82 Drilling cycle with dwell G83 Deep hole drilling G84 Tapping cycle G85 89-boring cycles G90 Absolute mode G91 Incremental mode 6.9.2. M codes These control the auxiliary functions of the machine. MOO Program stop M02 End of program M03 Spindle on, clockwise M04 Spindle on, counter clockwise M05 Spindle off M06 Tool change M07 Oil mist coolant on M08 Flood coolant on M09 Coolant off M30 End of tape

- 31. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/31 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c 6.10. WRITING A PROGRAM Figure 5.6. To cut a ‘S’-slot/groove with a point-to-point method and a continuous path/contouring system Table 5. Reference points and X and Y coordinates to cut a ‘S’-slot/groove with a point-to-point method and a continuous path/contouring system Position Coordinate (X) Coordinate (Y) C.P. 0 0 P. 1 45.0 -25.0 P. 2 70.0 -25.0 P. 3 60.0 -65.0 P. 4 45.0 -50.0 P. 5 60.0 -50.0 P. 6 49.393 -75.607 P. 7 38.787 -65.0 P. 8 15.0 -65.0

- 32. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/32 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c To machine the above component (as in Fig.5.6), below is the programme that can be followed; N10 G71 G90 S1500 T1 N130 G00 M00 N20 G00 X0 Y0 N140 G00 X0 Y0 N30 G00 X70.0 Y-25.0 Z10.0 N40 G01 Z-5.0 F250 N50 G03 I-25.0 J0 N60 X45.0 Y-50.0 N70 G01 X60.0 Y -50.0 N80 G02 I0 J-15.0 N90 X49.393 Y-75.607 N100 G01 X38.787 Y-65.0 N110 X15.0 Y-65.0 N120 Z10.0 Description of The Above Programme NXX – block number Block No. 10 – set machine to use metric unit, incremental coordinate, spindle speed 1500 rpm, choose tool no. 1. Block No. 20 – rapid movement to centre point (C.P). Block No. 30 - rapid movement to point 1 (P. 1), cutting tool distance is 5.0 mm from the surface of the work piece. Block No. 40 – cutting tool cuts 10.00 mm deep, feed 250 mm/min Block No. 50 – circular interpolation, counter clockwise, radius 25.0 mm

- 33. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/33 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c Block No. 60 – tool ends interpolation cutting at P. 4 Block No. 70 – linear interpolation until P. 5 Block No. 80 - circular interpolation, clockwise, radius 15.0 mm Block No. 90 - tool ends interpolation cutting at P. 6 Block No. 100 - linear interpolation until P. 7 Block No. 110 - linear interpolation until P. 8 Block No. 120 – tool rises up 10.0 mm Block No. 130 – program stops Block No. 140 - rapid return to centre point (C.P). 6.11. ADVANTAGES OF COMPUTER NUMERICAL CONTROL i. The component programming tape and the tape reader are used once only when the programme is copied into the computer memory, not only this practice wills same time but it will also reduce errors. ii. The programming tape can be edited on the shop floor, when the machine is placed/located. Editing, correction and optimising; such as machine tool operations, spindle speeds and speeds; are usually done in the test run of the tape. iii. Computer numerical control can easily changes into metric system if the programme is in the imperial units. iv. It is widely used in industry. It is easily adaptable in a computerised industry system. v. Increased flexibility – the machine can produce a specific part, followed by other parts with different shapes, and at reduces cost. vi. Greater accuracy – computers have a higher sampling rate and faster operation.

- 34. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/34 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c vii. More versatility – editing and debugging programmes, reprogramming, and plotting and printing part shape are simpler. viii. Programmes are stored on the machine ready for use. ix. Programmes and data can be modified on the machine.

- 35. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/35 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c ACTIVITY 6 6.1. Briefly state four (4) advantages of numerical control system. 6.2. You are given a drawing of a component. List down the steps you would take to operate a NC machine in order produce the component. 6.3. Write a short paragraph on three (3) basic components of a numerical control system.

- 36. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/36 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c FEEDBACK ON ACTIVITY 6 6.1. The advantages of numerical control system are: i. The component programming tape and the tape reader are used once only when the programme is copied into the computer memory, not only this practice wills same time but it will also reduce errors. ii. The programming tape can be edited on the shop floor, when the machine is placed/located. Editing, correction and optimising; such as machine tool operations, spindle speeds and speeds; are usually done in the test run of the tape. iii. Computer numerical control can easily changes into metric system if the program is in the imperial units. iv. It is widely used in industry. It is easily adaptable in a computerised industry system. v. Increased flexibility – the machine can produce a specific part, followed by other parts with different shapes, and at reduces cost. vi. Greater accuracy – computers have a higher sampling rate and faster operation. vii. More versatility – editing and debugging programs, reprogramming, and plotting and printing part shape are simpler. viii. Programs are stored on the machine ready for use. ix. Programs and data can be modified on the machine.

- 37. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/37 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c 6.2. Job Planning 1. Sketch the part. Add incremental or absolute dimensions. 2. Ascertain fixturing. Select fixtures which have minimal projections above the part. 3. Identify a set-up point. Locate the set-up point near: 1. A corner of the part 2. A spot above the fixture Consider space requirements for: 1. Part loading and unloading 2. Tool change. 4. Plan operation sequence Mark sequence pattern of sketch. Test program data for accuracy. 5. Record necessary data for each movement of the table and tool on the program sheet. 6. Record instructions for Identify, specific: the machine operator. 1. Tools needed. 2. Speed and feed data 3. Tool change points 4. Console switch setting 6.3.(a) Machine Tool - a device designed to cut away surplus material and leave a component of the required shape and size. It holds the work piece, cutting tool and moves the tool and work piece relative to one another precisely enough to achieve accuracy of size and surface finish. It can also alter the spindle speed and feed rates, tool changing, supply of coolant etc.

- 38. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/38 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c (b) The Control Unit - reads, decodes the part programme and provides the decoded instructions to the control loops of the machine axes of motion, and to control the machine tool operations. There are three main parts of the control unit namely, the Control Panel, the Tape Reader and the Processors (c) Control system - there are two types of control systems used on NC machines - the point-to-point system and the continuous-path system. The point-to-point systems operates only in straight lines, which are suitable for positioning moves on a drilling machine or limited use on a lathe or milling machine, where at best 45% cuts are possible with two axes running continuous path controls allow angular path and radius motion because the control interpolator has the ability to move the axis drive motors at varying velocities. The point-to-point controls were NC controls, while the continuous path controls could be NC or CNC controls.

- 39. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/39 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c SELF-ASSESSMENT 6 1. Numerical control machine can be done in absolute coordinate (G90) and incremental coordinates (G91). What is the difference between the two coordinates. 2. By using G90 and G 91 coordinates write a program to cut a component in is the .below figure. 30 J20 70 35 20 60

- 40. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re J3103/6/40 he he k k lic lic COMPUTER NUMERICAL CONTROL C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c FEEDBACK OF SELF-ASSESSMENT 6 1. (a) G90 Absolute mode - The data in the absolute system describes the next location always in terms of its relationship to the fixed zero point. The zero point when used as a programme datum is known as the programme origin. All moves are performed with respect to the axes zero. 1. (b) G91 Incremental mode - dimension or a movement with respect to the preceding point in a prescribed sequence of points. Each positioning move is described quantitatively in distance and in direction from a previous points rather than from a fixed zero reference point. 2. G 90 G 91 Point X Y X Y Origin Point 0 0 0 0 1 30 -70 30 -70 2 30 -40 0 30 3 70 -15 40 25 4 90 -35 20 -20 5 90 -70 0 -35

- 41. F T ra n sf o F T ra n sf o PD rm PD rm Y Y Y Y er er ABB ABB y y bu bu 2.0 2.0 to to re re he he k k lic lic C C w om w om w w w. w. A B B Y Y.c A B B Y Y.c