2. cost of quality

- 1. TOTAL QUALITY MANAGEMENT By: - Hakeem–Ur–Rehman IBIT–PU T MQ QUALITY COSTING MEASUREMENT & PRODUCTIVITY

- 2. QUALITY COST Feigenbaum defined quality costs as: “Those costs associated with the definition, creation, and control of quality as well as the evaluation and feedback of conformance with quality, reliability, and safety requirements, and those costs associated with the consequences of failure to meet the requirements both within the factory and in the hands of customers.” “QUALITY IS FREE” (Crosby)

- 3. COST OF QUALITY CATEGORIES OF QUALITY COST: – COST OF ACHIEVING GOOD QUALITY – COST OF POOR QUALITY COST OF ACHIEVING GOOD QUALITY – PREVENTION COSTS The cost of any action taken to investigate, prevent or reduce the risk of a non-conformity Include quality planning costs, designing products with quality characteristics, Training Costs, etc. – APPRAISAL COSTS The costs associated with measuring, checking, or evaluating products or services to assure conformance to quality requirements Include inspection & Testing Costs, Test Equipment Costs, Operator Costs, etc.

- 4. COST OF QUALITY CATEGORIES OF QUALITY COST: – COST OF ACHIEVING GOOD QUALITY – COST OF POOR QUALITY COST OF POOR QUALITY – INTERNAL FAILURE COSTS The costs arising within the organization due to non- conformities or defects include scrap, rework, process failure, downtime, and price reductions – EXTERNAL FAILURE COSTS The costs arising after delivery of product or service to the customer due to non-conformities or defects include complaints, returns, warranty claims, liability, and lost sales

- 6. GOAL OF COST OF QUALITY SYSTEM TO FACILITATE QUALITY EFFORTS THAT WILL LEAD TO OPERATING COST REDUCTION OPPORTUNITIES STRATEGY Direct attack on Failure Costs to minimize them Investment in Prevention activities Reduction in Appraisal Costs

- 7. MODEL OF OPTIMUM COST OF QUALITY

- 8. MEASURING AND REPORTING QUALITY COSTS INDEX NUMBERS – ratios that measure quality costs against a base value – LABOR INDEX ratio of quality cost to labor hours – COST INDEX ratio of quality cost to manufacturing cost – SALES INDEX ratio of quality cost to sales – PRODUCTION INDEX ratio of quality cost to units of final product

- 9. AN EVALUATION OF QUALITY COSTS & QUALITY INDEX NUMBERS EXAMPLE: The H&S Motor Company small motors (e.g., 3 hp) for use in lawnmowers and garden equipment. The company instituted a quality management program in 2004 and has recorded the following quality cost data and accounting measures for four years. YEAR 2004 2005 2006 2007 QUALITY COSTS Prevention $27,000 41,500 74,600 112,300 Appraisal 155,000 122,500 113,400 107,000 Internal Failure 386,400 469,200 347,800 544,400 External Failure 242,000 196,000 103,500 106,000 TOTAL $810,400 829,200 639,300 869,700 ACCOUNTING MEASURES Sales $4,360,000 4,450,000 5,050,000 5,190,000 Manufacturing Costs 1,760,000 1,810,000 1,880,000 1,890,000 The company wants to assess its quality–assurance program and develop quality index numbers using sales and manufacturing cost bases for the four–year period.

- 10. AN EVALUATION OF QUALITY COSTS & QUALITY INDEX NUMBERS: “EXAMPLE (Cont…)” Quality Index = [(Total Quality Costs) / Base] X 100 The Index Number for 2004 sales is: – Quality Cost per sale = [(810,400/4,360,000)] X 100 = 18.58% Year Quality Sales Index Quality Manufacturing Index 2004 18.58 46.04 2005 18.63 45.18 2006 12.66 34.00 2007 10.49 28.80 “The H&S Company quality index numbers reflect dramatically improved quality during he four – year period” Quality Costs as a Proportion of both sales & manufacturing costs improved significantly Quality Index Numbers are useful in showing trends in product quality over time and reflecting the impact of product quality relative to accounting measures with which managers are usually familiar

- 11. QUALITY INDEX NUMBERS: “QUESTION” Backwoods American, Inc., produces expensive water-repellent, down-lined parkas. The company implemented a total quality management program in 2002. Following are quality related accounting data that have been accumulated for the five year period after the program’s start. YEARS 2003 2004 2005 2006 2007 QUALITY COSTS (000s) Prevention $3.2 10.7 28.3 42.6 50.0 Appraisal 26.3 29.2 30.6 24.1 19.6 Internal Failure 39.1 51.3 48.4 35.9 32.1 External Failure 118.6 110.5 105.2 91.3 65.2 ACCOUNTING MEASURES (000s) Sales $2,700.6 2,690.1 2,705.3 2,810.2 2,880.7 Manufacturing Cost 420.9 423.4 424.7 436.1 435.5 Compute quality–sales indices and quality–cost indices for each of the five years. Is it possible to assess the effectiveness of the company’s quality management program from these index values?

- 12. QUALITY INDEX NUMBERS: “QUESTION” ANSWER: These index values do not provide much information regarding the effectiveness of the quality assurance program. They are, however, useful in making comparisons from one period to the next and in showing trends in product quality over time.

- 13. QUALITY MANAGEMENT AND PRODUCTIVITY Productivity – ratio of output to input Yield: – is a measure of output used as an indicator of productivity – Improved quality increases product yield Yield=(total input)(% good units) + (total input)(1-%good units)(% reworked) or Y=(I)(% G)+(I)(1-% G)(% R)

- 14. COMPUTING PRODUCT YIELD EXAMPLE: – The H & S Motor company starts production for a particular type of motor with a steel motor housing. The production process begins with 100 motors each day. The percentage of good motors produced each day average 80% and the percentage of poor–quality motors that can be reworked is 50%. The company wants to know the daily product yield and the effect on productivity if the daily percentage of good–quality motors is increased to 90%. Yield=(total input)(% good units) + (total input)(1-%good units)(% reworked) Y=(I)(% G)+(I)(1-% G)(% R) Y = (100)(0.80) + (100)(1 – 0.80)(0.50) = 90 Motors If product quality is increased to 90% good motors, the yield will be: Y = (100)(0.90) + (100)(1 – 0.90)(0.50) = 95 Motors A 10% point increase in quality products results in a 5.5% ((95/ 90 )*100) increase in productivity output.

- 15. COMPUTING PRODUCT YIELD “QUESTION” The Colonial House furniture company manufactures two-draw oak file cabinets that are sold unassembled through catalogues. The company initiates production of 180 cabinets’ packages each week. The percentage of good-quality cabinets averages 83% per week, and percentage of poor- quality cabinets that can be reworked is 60%. a) Determine the weekly product yield of file cabinets. b) If the company desires a product yield of 174 units per week, what increase in the percentage of good quality products must results?

- 16. PRODUCT COST PER UNIT Y RKIK rd ))(())(( + =Product Cost where: Kd = direct manufacturing cost per unit I = input Kr = rework cost per unit R = reworked units Y = yield

- 17. COMPUTING PRODUCT COST PER UNIT EXAMPLE: – The H & S Motor company has a direct manufacturing cost per unit of $30, and motors that are of inferior quality can be reworked for $12 per unit. From previous Example, 100 motors are produced daily, 80% (on average) are of good quality and 20% are defective. Of the defective motors, half can reworked to yield good–quality products. Through its quality management program, the company has discovered a problem in its production process that, when corrected (at a minimum cost), will increase the good – quality products to 90%. The company wants to assess the impact on the direct cost per unit of improvement in product quality. The Original manufacturing cost per motor is: Product Cost = [($30)(100) + ($12)(10)] / 90 motors = $34.67 per motor The manufacturing cost per motor with the quality improvement is: Product Cost = [($30)(100) + ($12)(5)] / 95 motors = $32.21 per motor “The improvement in the production process as a result of the quality management program will result in a decrease of $2.46 per unit, or [(34.67–32.21)/34.67] X 100 = 7.1%, in direct manufacturing cost per unit as well as a 5.5% increase in product yield (computed in previous example), with a minimal investment in Labor, plant, or equipment. Y RKIK rd ))(())(( + =

- 18. COMPUTING PRODUCT COST PER UNIT: “QUESTION” The Omega Shoe Company manufactures a number of different styles of athletic shoes. Its biggest seller is the X–pacer running shoe. In 2005 Omega implemented a quality–management program. The company’s shoe production for the past three years and manufacturing costs are as fellows. YEAR 2005 2006 2007 Units Produced (Input) 32,000 34,600 35,500 Manufacturing Cost $278,000 291,000 305,000 Percent good quality 78% 83% 90% Only one–quarter of the defective shoes can be reworked, at a cost of $2 apiece. Compute the manufacturing cost per good product for each of the three years and indicate the annual percentage increase or decrease resulting from the quality management program.

- 19. COMPUTING PRODUCT COST PER UNIT: “QUESTION” ANSWER

- 20. COMPUTING PRODUCT YIELD FOR MULTISTAGE PROCESSES Y = (I)(%g1)(%g2) … (%gn) where: I = input of items to the production process that will result in finished products gi = good-quality, work-in-process products at stage i

- 21. COMPUTING PRODUCT YIELD FOR MULTISTAGE PROCESS EXAMPLE: – At the H&S motor company, motors are produced in a four– stage process. Motors are inspected following each stage, with percentage yields (on average) of good–quality, work in process units as follows: STAGE AVERAGE PERCENTAGE GOOD QUALITY 1 0.93 2 0.95 3 0.97 4 0.92 1. The company wants to know the daily product yield for product input of 100 units per day. 2. Furthermore, it would like to know how many input units it would have to start with each day to result in a final daily yield of 100 good – quality units.

- 22. COMPUTING PRODUCT YIELD FOR MULTISTAGE PROCESS SOLUTION: – Y = (I)(%g1)(%g2)(%g3)(%g4) = (100)(0.93)(0.95)(0.97)(0.92) – Y = 78.8 motors Thus, the production process has a daily good – quality product yield of 78.8 motors. – To determine the product input that would be required to achieve a product yield of 100 motors, “I” is treated as a decision variable when Y equals 100: – I = (Y) / (%g1)(%g2)(%g3)(%g4) – I = (100) / (0.93)(0.95)(0.97)(0.92) – I = 126.8 motors To achieve output of 100 good – quality motors, the production process must start with approximately 127 motors.

- 23. COMPUTING PRODUCT YIELD FOR MULTISTAGE PROCESS: “QUESTION” The Colonial House Furniture Company manufactures four–drawer oak filing cabinets in six stages. In the first stage, the boards forming the walls of the cabinet are cut; in the second stage, the front drawer panels are wood-worked; in the third stage, the boards are sanded and finished; in the fourth stage, the boards are cleaned, stained, and painted with a clear finish; in the fifth stage, the hardware for pulls, runners, and fittings is installed; and in the final stage, the cabinets are assembled. Inspection occurs at each stage of the process, and the average percentage of good quality units are as fellows. Stage Average Percentage Good Quality 1 87% 2 91% 3 94% 4 93% 5 93% 6 96% The cabinets are produced in weekly production runs with a product input for 300 units. a. Determine the weekly product yield of good–quality cabinets. b. What would weekly product input have to be in order to achieve a final weekly product yield of 300 cabinets?

- 24. QUALITY–PRODUCTIVITY RATIO QPR: – productivity index that includes productivity and quality costs – It increases if either processing cost or rework costs or both decrease. – It increases if more good-quality units are produced relative to total product input(i.e., number of units that begin the production process) QPR = (non-defective units) (input) (processing cost) + (defective units) (reworked cost)

- 25. COMPUTING QUALITY & PRODUCTIVITY RATIO EXAMPLE: – The H&S Motors Company produces small motors at a process cost of $30 per unit. Defective motors can be reworked at a cost of $12 each. The company produces 100 motors per day on average 80% good- quality motors., resulting in 20% defects, 50% of which can be reworked prior to shipping to customers. The company wants to examine the effects of: 1. Increase the production rate to 200 motors per day 2. Reducing the processing cost to $26 and the rework cost to $10 3. Increasing, through quality improvement, the product yield of good quality products to 95% 4. The combination 2 & 3 SOLUTION: – QPR for the base case: QPR = [(80 + 10) / {(100)($30) + (10)($12)}] X 100 QPR = 2.89 QPR = (non-defective units) (input) (processing cost) + (defective units) (reworked cost)

- 26. COMPUTING QUALITY & PRODUCTIVITY RATIO SOLUTION: – Case#1: “Increase input to production capacity of 200 units” QPR = [(160 + 20) / {(200)($30) + (20)($12)}] X 100 QPR = 2.89 “Increasing production capacity alone has no effect on the QPR” – Case#2: “Reduce processing cost to $26 and rework cost to $10” QPR = [(80 + 10) / {(100)($26) + (10)($10)}] X 100 QPR = 3.33 “Processing & Rework cost decreases caused the QPR to increase” – Case#3: “Increasing, through quality improvement, the product yield of good quality products to 95% ” QPR = [(95 + 2.5) / {(100)($30) + (2.5)($12)}] X 100 QPR = 3.22 “Again, QPR increases as product quality improves” – Case#4: “Decrease costs & increase initial good-quality units” QPR = [(95 + 2.5) / {(100)($26) + (2.5)($10)}] X 100 QPR = 3.71 “The larger increase in the QPR results from decreasing costs & increasing initial good quality products through improved quality”

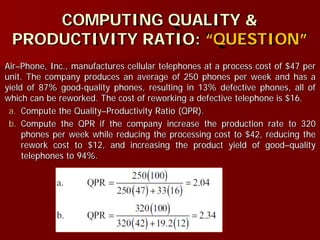

- 27. COMPUTING QUALITY & PRODUCTIVITY RATIO: “QUESTION” Air–Phone, Inc., manufactures cellular telephones at a process cost of $47 per unit. The company produces an average of 250 phones per week and has a yield of 87% good-quality phones, resulting in 13% defective phones, all of which can be reworked. The cost of reworking a defective telephone is $16. a. Compute the Quality–Productivity Ratio (QPR). b. Compute the QPR if the company increase the production rate to 320 phones per week while reducing the processing cost to $42, reducing the rework cost to $12, and increasing the product yield of good–quality telephones to 94%.

![AN EVALUATION OF QUALITY COSTS & QUALITY

INDEX NUMBERS: “EXAMPLE (Cont…)”

Quality Index = [(Total Quality Costs) / Base] X 100

The Index Number for 2004 sales is:

– Quality Cost per sale = [(810,400/4,360,000)] X 100 = 18.58%

Year Quality Sales

Index

Quality Manufacturing

Index

2004 18.58 46.04

2005 18.63 45.18

2006 12.66 34.00

2007 10.49 28.80

“The H&S Company quality index numbers reflect dramatically improved quality

during he four – year period”

Quality Costs as a Proportion of both sales & manufacturing costs improved

significantly

Quality Index Numbers are useful in showing trends in product quality over time

and reflecting the impact of product quality relative to accounting measures with

which managers are usually familiar](https://image.slidesharecdn.com/2-161104025452/85/2-cost-of-quality-10-320.jpg)

![COMPUTING PRODUCT COST PER UNIT

EXAMPLE:

– The H & S Motor company has a direct manufacturing cost per unit of $30, and

motors that are of inferior quality can be reworked for $12 per unit. From

previous Example, 100 motors are produced daily, 80% (on average) are of good

quality and 20% are defective. Of the defective motors, half can reworked to

yield good–quality products. Through its quality management program, the

company has discovered a problem in its production process that, when corrected

(at a minimum cost), will increase the good – quality products to 90%. The

company wants to assess the impact on the direct cost per unit of improvement

in product quality.

The Original manufacturing cost per motor is:

Product Cost

= [($30)(100) + ($12)(10)] / 90 motors

= $34.67 per motor

The manufacturing cost per motor with the quality improvement is:

Product Cost = [($30)(100) + ($12)(5)] / 95 motors = $32.21 per motor

“The improvement in the production process as a result of the quality management program will

result in a decrease of $2.46 per unit, or [(34.67–32.21)/34.67] X 100 = 7.1%, in direct

manufacturing cost per unit as well as a 5.5% increase in product yield (computed in previous

example), with a minimal investment in Labor, plant, or equipment.

Y

RKIK rd ))(())(( +

=](https://image.slidesharecdn.com/2-161104025452/85/2-cost-of-quality-17-320.jpg)

![COMPUTING QUALITY & PRODUCTIVITY RATIO

EXAMPLE:

– The H&S Motors Company produces small motors at a process cost of

$30 per unit. Defective motors can be reworked at a cost of $12 each.

The company produces 100 motors per day on average 80% good-

quality motors., resulting in 20% defects, 50% of which can be reworked

prior to shipping to customers. The company wants to examine the

effects of:

1. Increase the production rate to 200 motors per day

2. Reducing the processing cost to $26 and the rework cost to $10

3. Increasing, through quality improvement, the product yield of good

quality products to 95%

4. The combination 2 & 3

SOLUTION:

– QPR for the base case:

QPR = [(80 + 10) / {(100)($30) + (10)($12)}] X 100

QPR = 2.89

QPR =

(non-defective units)

(input) (processing cost) + (defective units) (reworked cost)](https://image.slidesharecdn.com/2-161104025452/85/2-cost-of-quality-25-320.jpg)

![COMPUTING QUALITY & PRODUCTIVITY RATIO

SOLUTION:

– Case#1: “Increase input to production capacity of 200 units”

QPR = [(160 + 20) / {(200)($30) + (20)($12)}] X 100

QPR = 2.89

“Increasing production capacity alone has no effect on the QPR”

– Case#2: “Reduce processing cost to $26 and rework cost to $10”

QPR = [(80 + 10) / {(100)($26) + (10)($10)}] X 100

QPR = 3.33

“Processing & Rework cost decreases caused the QPR to increase”

– Case#3: “Increasing, through quality improvement, the product yield of

good quality products to 95% ”

QPR = [(95 + 2.5) / {(100)($30) + (2.5)($12)}] X 100

QPR = 3.22

“Again, QPR increases as product quality improves”

– Case#4: “Decrease costs & increase initial good-quality units”

QPR = [(95 + 2.5) / {(100)($26) + (2.5)($10)}] X 100

QPR = 3.71

“The larger increase in the QPR results from decreasing costs &

increasing initial good quality products through improved quality”](https://image.slidesharecdn.com/2-161104025452/85/2-cost-of-quality-26-320.jpg)