5 S Intro

- 2. Lean Culture Fundamentals Set In Order Sort Standardize Shine Sustain

- 3. Objectives To understand the importance of 5S to our lean initiatives To know what the 5S’s are and the key benefits of each To be able to implement 5S across the facility

- 4. Agenda What is 5S? The 5S’s Benefits Activities needed Recap

- 5. 5S

- 6. 5S Focuses on developing stability and standardization in the organization It is difficult to make and maintain other improvements with these two characteristics Helps to establish the right discipline and culture for lean implementation Can provide benefits in areas from safety to quality

- 7. 2. Set In Order Keep needed items in the correct place to allow for easy and immediate retrieval 1. Sort 3. Shine 4. Standardize Clearly distinguish needed items from unneeded items and remove the unneeded Make the best practices and cleaning processes the standard 5. Sustain Keep the workplace clean and polished Make a habit of maintaining established procedures and develop the discipline to maintain the S’s

- 8. House of Lean Stability Standardization Customer Focus

- 9. 5S ort et in Order hine tandardize ustain

- 10. 5 S My Garage

- 12. Just Across The Road At Giant

- 13. Sort

- 14. Seiri – Sort Everything at the workplace should be related to the work being done there Only what is needed, in the amounts needed, when it is needed Removal of all items that are not needed for current production Does not mean we only remove items we are sure we will never need, we go down to the bare essentials

- 15. Benefits of Sort Keeps the work area clean and clutter free reduces risk of safety incidents Creates “extra” work space where necessary items can be placed Reduces time spent searching for tooling and possible tooling errors Removing supplies, materials and paper work not required to do the work help improve efficiency

- 16. Red-Tagging Method for identifying potentially unneeded items in the plant, evaluating their usefulness and dealing with them appropriately The most difficult part of red-tagging is differentiating what is needed from what is not Having clear criteria will help with this differentiation

- 17. Red-Tagging The 3 Questions Is this item needed? If it is needed, is it needed in this quantity? If it is needed, does it need to be located here? Holding Areas A “safety net” between questioning whether something is needed and getting rid of it Items held for a set time (30 days)

- 18. Red Tagging

- 19. Red-Tagging Steps Establish Red Tag targets What area will be evaluated What types of items will be evaluated Establish Red Tag Criteria Take a look at the production schedule for the next month Items needed for that schedule are kept in the location Items not needed for the schedule are disposed of or stored in another location

- 20. Red-Tagging Criteria The usefulness of the item to perform the work at hand (typical month’s production) If it isn’t needed it should be disposed of The frequency with which the item is needed If it’s needed infrequently it can be stored away from the work area The quantity of the item needed to perform this work Excess items can be disposed of or stored away

- 21. Red Tag Criteria Quantity exceeds demand Quantity matches pitch Quantity Used infrequently (or not at all) Used daily or weekly Frequency of Use No longer used (obsolete/defective) Required at this workstation Usefulness Red Tag No Red Tag Criteria

- 22. Red-Tagging Steps Establish Red Tag holding area Area set aside to store red-tagged items that need further evaluation Red tag items Team goes through and red tags all items they believe can be removed from the area or disposed of All items should be documented on the Red Tag Disposition Log

- 23. Red Tag Disposition Log

- 24. Red-Tagging Steps Evaluate the red-tagged items Evaluate items against criteria established in step 2 Remove questionable items to the holding area Assign responsibility of each item to someone on the team After 30-days items should be reviewed one final time

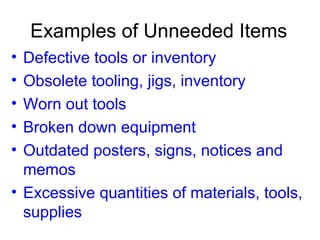

- 25. Examples of Unneeded Items Defective tools or inventory Obsolete tooling, jigs, inventory Worn out tools Broken down equipment Outdated posters, signs, notices and memos Excessive quantities of materials, tools, supplies

- 26. Examples From Our Plants

- 27. After Sorting After Sorting

- 28. Set in Order

- 29. Seiton – Set in Order Everything that remains after Sort should have a place A systematic arrangement for the most efficient and effective retrieval Arrange things so that they are they are easy to use, and label them so that anyone can find them and put them away An orderly workplace promotes work flow and eliminates extra motion

- 30. Seiton – Set in Order For every item in the workplace we will need to: Identify it Allocate a place and store it Determine how much/how many to store at the work place Make an outline for it

- 31. Benefits of Set In Order Safety is improved Ergonomic storage of tools and materials Clean clutter free floors and aisles Tools and parts are stored properly so there’s less damage Less likely to pull wrong parts, tools Less waste of motion – reduced searching for materials, tools & supplies Reduced inventory of materials, supplies

- 32. Keys to Set In Order Standardization Creating a consistent way that tasks and procedures are carried out Visual Controls Used to identify standards Examples Where items belong and how many belong there Standard procedures

- 33. Setting in Order Decide where to keep needed items Keep frequently used items at point of use Screwdrivers next to screws, order of use Organize items in a way that makes sense Make it easy for anyone to find them, use them and put them back after use Use outlines and labels Make it obvious when items are not in their correct place

- 34. Setting in Order Decide where to keep needed items Locate items according to their frequency of use (higher frequency = closer to you) Store items together if they are used together (i.e. – ratchets with bolts) Store them in the sequence they are used Consider tools on retractable cords (overhead) Simplify – use one tool for multiple functions

- 35. 5S Map (Spaghetti Diagram) Helps show the amount of motion and travel an operator encounters in a typical day Used to evaluate current locations of parts, tools, dies, equipment, machines, materials, etc Experiment with new layouts Implement

- 36. Setting in Order Identify locations Once the best locations have been chosen we need to identify these locations so that everyone will know what goes where and how many of each belong there Make it easy for anyone to find them, use them and put them back after use Make it obvious when items are not in their correct place

- 37. Identifying Locations Signboards Painting Color Coding Outlining Post Spaghetti Diagram

- 38. Signboards Types Amount Indicators Specific number or min /max lines Location Indicators Inventory, tooling A1, B1, B2, etc Item Indicators Machine Name/Process Inventory, parts, Equipment

- 39. Painting / Marking Used for identifying locations on floors and walkways Mark off working areas from walk ways May show: Flow direction Storage locations Hazards or safety call outs Areas where items should not be stored

- 40. Painting / Marking Color coding Shows which parts, tools, etc are used for which purpose or used together Used for storage containers Coating containers color of coating Outlining Way to show what parts, tools go where

- 41. Examples of Set In Order

- 42. After Set In Order

- 43. Shine

- 44. Seiso – Shine We keep everything swept and clean Emphasizes the removal of dirt, grime, dust, etc from the workplace Keep everything in top condition so that when we need to use it, it is ready to be used A clean workplace implies quality work

- 45. Benefits of Shine Safety No debris, fluids or materials on floor to cause slips, trips or falls Morale Dirty work places lead to low morale and pride for what we do Customer Service / Satisfaction Customers touring a clean and organized facility are more likely to appreciate the efforts

- 46. Benefits of Shine Machine Reliability Easier to identify issues on clean machines so they can be addressed sooner Cleaning also means inspection Equipment / Tools Clean equipment functions properly Easier to spot leaks on a clean, shiny floor or machine than it is on a dirty, grimy one

- 47. Shine Activities Make a list of Shine Targets Warehouse items, equipment, space Decide Shine assignments and methods Who will do what, what is needed and how will it be done Prepare Shine tools Make sure we have what we need Remember Set in Order – easy access Start Shining

- 48. Post Shine Once we have cleaned and organized an area we need to put plans in place to maintain it We don’t want to slide backwards Take advantage of operator sensitivity towards their equipment They run it everyday and are more likely to notice symptoms ahead of a breakdown Establish a “Maintenance Needed” list

- 50. After Shine

- 51. Standardize

- 52. Seiketsu – Standardize All procedures, practices and activities established with the first 3S’s occur consistently and at regular intervals No use in going through Sort, Set in Order or Shine if we’re going to let things go back to the way they were Makes implementing Sort, Set in Order and Shine a daily habit so that conditions are maintained at desirable levels

- 53. Benefits of Standardizing Safety Aisle ways and floors are clear and hazard free Efficiency Storage sites remain organized Materials, tools and equipment maintained Maintains benefits gained from Sort, Set in Order and Shine

- 54. Establishing the Habits Decide who is responsible for which activities Activity Charts, Checklists, Schedules Integrate duties into regular work activities 5 Minute 5S, Cleaning / Inspection Check on well conditions are being maintained 5S Audits

- 55. 1. Decide who is responsible for which activities People need to know exactly what they are responsible for doing and exactly when, where and how to do it Standard procedures for how things are done should be developed 5S Schedules Shows who is responsible for cleaning which areas and when they must do it

- 56. 5S Schedule

- 58. 2. Integrate duties into regular work activities Visual 5S Makes conditions obvious at a glance Signboards, Min/Max inventory lines Color coding “ Five Minute 5S” Complete specific tasks to be done in a devoted block of time Cleaning and inspections are done daily and should not require a lot of time

- 59. 2. Integrate duties into regular work activities Cleaning Inspection Checklist A list of all the clean / inspection check items and what the operator should be checking Not simply a visual check, we must use all of our “senses” Sounds different Burning oil, hot rubber Vibrations, loose parts, running hot Leaks, shavings

- 60. 2. Integrate duties into regular work activities Correcting equipment problems Instant Maintenance Operators fix or improve the problems they discover Oil levels, dirty sight pipe Requested Maintenance Use “Maintenance Needed Log” and maintenance tags Tag is removed and checked off when complete

- 61. 3. Check on well conditions are being maintained 5S Audits Checking level of effectiveness of the first 3S’s (Sort, Set in Order and Shine) Use a sliding scale Conducted routinely by operators, supervisors and managers

- 62. Establishing the Habits Post “before” and “after” photos A good reminder of what we don’t want to go back to and of the impact we have had Establish standard 5S procedures and activity charts Identify and standardize best practices Finding ways to prevent dirt or to make impossible for things to put things in the wrong place

- 65. Sustain

- 66. Shitsuke – Sustain Having the discipline to maintain the correct procedures / standards over time Creating conditions, or an atmosphere, that encourage the constant practice of good habits and the elimination of bad ones

- 67. Favorable Conditions Workforce that is educated on the benefits of 5S Time allowed to practice and maintain Organized, focused effort Management support and drive Efforts that are recognized and rewarded Needs to be beneficial and satisfying

- 69. 5 S After Sustain

- 70. RECAP

- 71. The 5S’s Sort – to put things in order Remove what is not needed & keep what is needed Set in order - proper arrangement Place things in a way that they are easily accessible whenever they are needed Shine – clean Keep things clean & polished; no trash in workplace Standardize Standardize best practices / processes for cleaning Sustain – commitment and self-discipline Develop an attitude and culture that follows the other 4S’s

- 73. BENEFITS Reduced set-up times Reduced cycle times Reduce searching time Increased floor space Reliable Delivery Less wasted labor Better equipment reliability Higher Quality Lower cost Lower safety incident/accident rate

- 74. Before After

- 75. Tool Storage Before After

- 76. Tool Identification / Location Before After

- 77. Consolidation of Production Tooling to One Central Location Before Before Before After Reduced walking distance between work stations and tooling racks by approximately 49%

- 78. Before

- 79. After

- 80. Before After

- 81. The Rules… Remove fixed ideas Think of ways to make it possible No excuses needed Go for the simple solution, not the perfect one Correct mistakes right away Repeat ‘Why’ 5 times Ask ideas from many people There is no end to improvement

- 82. Any Questions?

- 83. Attitude is Critical “ If you think you can or you think you can’t, you’re right.” Henry Ford