Fabric structure and design plain weave and derivatives

- 1. Fabric structure 1 CLASSIFICATION OF TEXTILE FABRICS; CLASSIFICATION OF WOVEN FABRICS- SIMPLE, COMPOUND AND COMPLEX; FUNDAMENTAL ASPECTS OF WOVEN FABRICS - COUNT OF GRAPH PAPER, FACTORS INFLUENCING THE SELECTION OF APPROPRIATE COUNT OF GRAPH PAPER, GRAPHICAL REPRESENTATION OF STRUCTURE OF A WOVEN FABRIC- WARP WAY AND WEFT WAY; STUDY OF PLAIN WEAVE, ORNAMENTATION OF PLAIN WEAVES; STUDY OF DERIVATIVE STRUCTURES OF PLAIN WEAVE – REGULAR AND IRREGULAR WARP RIB, WEFT RIB, HOPSACK WEAVES. CATCH-CORD TECHNIQUE FOR WEAVING WARP RIB AND HOP-SACK; DESIGN, DRAFT, DENTING, PEG/TIE-UP PLAN AND THREAD INTERLACING DIAGRAM OF ABOVE WEAVES. 15-06-2021 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 2. Introduction Woven fabrics are composed of longitudinal or warp threads and transverse or weft threads, interlaced with one another according to the class of structure and form of design that are desired. The terms “Chain or Twist are applied to the warp, and the warp threads are known individually as, “Ends”, while the terms “picks and filling” are applied to the weft threads. In the following the term threads is used in referring to warp and weft collectively, but in order to distinguish clearly one series from the other the warp threads are mostly described as, “ends” and the weft threads as, “picks”. Fabrics are classified into woven, knitted and non – woven. Woven fabrics are classified into simple, compound and complex basing on its woven structures. It is dealt with the fundamental aspects of woven fabrics, formation of fabric in the process of weaving. Warp ends and weft picks interlace with each other in the process of weaving is graphically represented for easy understanding. 15-06-2021 2 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 3. CLASSIFICATION OF FABRICS Woven Fabrics – Woven fabrics are produced on weaving machine which is called as loom, may be handloom or power loom. Woven fabric is the result of warp and weft interlacement. Woven fabrics are used as dress material and home Furnishing. Knitted Fabrics – Knitted fabrics are produced on circular knitted machine. There is no warp and weft weaving process on this knitting machine. But fabrics are manufactured with one series of threads. Knitted fabrics are used as casual dress material and under garments. Non – Woven fabrics – These are manufactured by compressing the fibres and used for Industrial purpose like laying roads, Helipads, etc. and penetrating into House hold purpose like door mats, cleaning brush, etc. 15-06-2021 3 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 4. CLASSIFICATION OF FABRICS Simple Fabrics – Warp and weft interlace at 90° and remain at its original position.Examples are basic weaves like plain, twill, sateen and its derivatives. Compound Fabrics – One series of either warp or weft rise from the foundation of fabric to form piles. Examples are Terry, Velvet and Velveteen. And also multi layer fabrics like double cloth & triple cloth Complex Fabrics – Some threads inter weave on left and right to adjacent threads. Examples are Gauze and Leno. 15-06-2021 4 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 5. Fundamental aspects of woven fabrics: Fundamental aspects of woven fabrics are its appearance, feel, handle, drape, weight and strength. Fabric structure subject refers to mostly woven fabrics as per the syllabus. Woven fabrics are composed of two series of threads namely, longitudinal and transverse threads. Longitudinal threads are in vertical axis and transverse threads are in horizontal axis. A sheet of longitudinal threads are called as, “Warp“ and one thread of warp is called as, “End“. All transverse threads in a fabric are called as, “Weft” and one thread of weft is called as, “Pick”. Warp is also called as, “twist or chain” and weft is called as, “filling”. Warp and weft threads interlace with each other as per the design. 15-06-2021 5 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 6. Graphical representation of Structure of a woven fabric Woven fabrics are composed of warp and weft. Ends in warp and picks in weft interlace with each other. Graphical representation of an end and pick is illustrated. 15-06-2021 6 Warp direction Weft direction Warp up Weft up R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 7. Creation of draft, peg plan and tie – up from the weave repeat Design - Design in textile language will have a definite shape, form and character. A design will have its shape on number of ends and picks, which interlace with each other. Mark on design paper indicates end up and blank end down. Draft - A draft indicates the number of healds used to produce a given design and the order in which the warp ends are threaded through the mail eyes of the healds. Draft is derived from the given design as differently interlacing ends in its order. Peg plan - Lifting plan (Weaving or pegging plan) defines the selection of healds to be raised or lowered on each successive insertion of the pick of weft. Tie up - Tie – up is the process of connections between heald shafts and treadles with the aid of lams and “ V “ ropes. Number of heald shafts are 4 which are in draft, where as treadles are to be decided from peg plan or lifting plan. To decide number of treadles, read interlacement of all picks in peg plan and allot Numbers to each differently interlacing pick in its order 15-06-2021 7 Tie up R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 8. Types of drafts The various drafts are classified as follows : (i) Straight draft (ii) Pointed draft (iii) Skip and sateen draft (iv) Broken draft (v) Divided draft (vi) Grouped draft (vii) Curved draft (viii) Combination draft 15-06-2021 8 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 9. Straight draft This system is particularly useful in weaving very densely set fabrics where normally a small number of healds is required. In order that the mails will not be too crowded on the shafts and to reduce friction and rubbing between the ends it is customary to use more healds than the minimum necessary for the weave. This is the most commonly used draft. It is the simplest of all the types of draft plans. In this kind of draft the drafting order progresses successively from first to the last heald frame. Thus the first warp end of a weave is drawn through the first heald shaft, the second warp through the second heald frame and so on. One important feature of the straight draft that distinguishes it from other types of draft plans is that the peg or lifting plan is same as the design. 15-06-2021 9 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 10. Pointed draft Point drafts are used for weaves which are symmetrical about the centre, and they are frequently employed to produce waved or diamond effects. The main advantage of this system is that it allows the production of quite large effects economically which if attempted on the straight drafts would require almost twice the number of healds. The method used to construct these drafts and it will be seen that to achieve a well defined point in the design the ends are drawn in straight order starting with heald 1 and finishing with the last heald in the number employed, whereupon the order of drawing-in of the consecutive ends is reversed. The first and the last healds carry only one end each, whilst all the healds in the middle carry two ends each per repeat of the draft. As a result, using this system of drafting the number of ends per repeat of the design is: 2 x (No. of healds) less 2. Further extension of design size is possible with special adaptations of the point draft and several examples of this are given in chapters devoted to waved twills and diamonds 15-06-2021 10 Design Draft Peg plan R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 11. Skip draft The skip draft is suitable for weaving fabrics having heavy warp thread density. In this kind of draft plan the number of heald frames may be twice or more than the minimum required for a weave. The purpose of using more heald frames than the minimum recommended is only to distribute the warp threads more uniformly so as to prevent abrasion of the threads due to overcrowding. The heald frames are divided into two groups. All even numbered warp threads are drawn through the first group of heald frames and all odd numbered warp ends are drawn through the second group of heald frames. The sateen draft serves the same purpose as the skip draft. A skip draft is normally employed for weaves such as plain and twill upto a repeat of 4. Whereas the sateen draft is used for weaves having repeat size of more than 5. 15-06-2021 11 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 12. Sateen drafts: Sateen drafts: The purpose of sateen draft is similar to skip draft in that each is used to reduce friction between adjacent warp ends and to alleviate the overcrowding of the mails. In sateen drafts, however, this result is not achieved by duplication of the healds but by staggering the end placing. 15-06-2021 12 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 13. Broken draft A broken draft almost resembles the pointed draft. However the pointed effect is broken. This type of draft is suitable for weaves such as herringbone twills. 15-06-2021 13 Broken draft Herring bone twill Peg plan R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 14. Divided draft This draft is used for weaves having two series of warp threads such as terry, double cloth, warp backed cloth etc. 15-06-2021 14 Draft Design Peg plan R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 15. Grouped draft These drafts are employed for the production of stripe and check designs, in which the stripes have different weaves or their combinations. This draft is used for producing the fabric with two different stripes. The repeat of the draft is determined by the number of stripes and the number of threads in each stripe. The number of shafts in the draft depends upon the number of stripes and the warp repeat of weave of each stripe 15-06-2021 15 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 16. Curved draft Construction of curved twills does not come under any category. To decide the draft order, there is no rule need to apply. To derive and decide the draft, a curved line is drawn to suit the requirement. Mark draft over the curved line finalized for curved twill. Then base weave is arranged as per the draft order. 15-06-2021 16 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 17. Combined draft Various methods of drawing in can be combined in one draft for producing a certain type of fabric. Two or more drafts described above can be applied simultaneously, for example, straight and skip or sateen, grouped and curved, and so on. Combined draft is the most complicated and can be chosen only if there are some technological or economical reasons. The designer having a great experience can do it properly. 15-06-2021 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM 17

- 18. Plain weave The plain weave is variously known as “calico” or “tabby” weave. It is the simplest of all weaves having a repeat size of 2. The range of application of this weave is wide. The plain weave has the following characteristics : (i) It has the maximum number of binding points (ii) The threads interlace on alternate order of 1 up and 1 down. (iii) The thread density is limited (iv) Cloth thickness and mass per unit area are limited. (v) It produces a relatively stronger fabric that is obtained by any other simple combination of threads, excepting that of “gauze”or “cross weaving”. 15-06-2021 18 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 19. Plain weave 15-06-2021 19 The principle involved in the construction of plain cloth is the interlacement of any two continuous threads either warp or weft in an exactly contrary manner to each other, with every thread in each series passing alternately under and over consecutive threads of other series interlaces uniformly throughout the fabric. By this plan of interlacement, every thread in each series interlaces with every thread in the other series to the maximum extent, thereby producing a comparatively firm and strong texture of cloth. A complete unit of the plain weave occupies only two warp threads and two picks of weft (Fig. 3.1), which is the design for that weave. R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 20. Plain weave The chart below shows the derivatives/modifications of plain weave : 15-06-2021 20 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

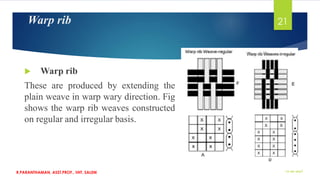

- 21. Warp rib Warp rib These are produced by extending the plain weave in warp wary direction. Fig shows the warp rib weaves constructed on regular and irregular basis. 15-06-2021 21 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 22. Weft rib These are constructed by extending the plain weave in weft direction as shown in Fig. 15-06-2021 22 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 23. Matt Rib These weaves are also variously known as hopsack or basket weaves. The matt rib structures result from extending the plain weave in both directions. The regular and irregular types are shown in Fig. 15-06-2021 23 Matt Rib Regular Matt Rib Irregular R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 24. Ornamentation of plain weave fabrics Following are some of the ways to ornament plain weave fabrics: 1) Plain weave is ornamented by using mono colour (single colour) in warp and the same mono colour in weft, results the formation of solid colour effect. 2) Plain weave is ornamented by using mono colour (single colour) in warp and different mono colour in weft, resulting the formation of shot effect. This is commercially called as cross colour or double shade effect. 3) Plain weave is ornamented by using mono colour (single colour) in warp and white in weft, resulting the formation of cross over effect. This is commercially called as chambare effect. 15-06-2021 24 1 2 3 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 25. Ornamentation of plain weave fabrics 4) Plain weave is ornamented by using multi colours in warp and single colour in weft, resulting the formation of stripe effect. 5) Plain weave is ornamented by using multi colours in warp and multi colours in weft, resulting the formation of check effect. 6) Plain weave is ornamented by using different counts like 80 and 20 in warp and only 80 in weft resulting the formation of rib stripe or doria stripe effect. 15-06-2021 25 4 5 6 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 26. Ornamentation of plain weave fabrics 7) Plain weave is ornamented by using different counts like 80 and 20 in warp and same 80 and 20 in weft resulting formation of rib check or doria check effect. 8) Plain weave is ornamented by using different material like cotton in warp and silk in weft or vice – versa or any other material, resulting the formation of union fabric. 9) plain weave is ornamented by using different denting orders like 2 ends / dent for 6 times and 3 ends / dent for 6 times or any irregular denting order will result the formation of rib effect. 10) Plain weave is ornamented by using two different tension warp beams to weave seersucker fabrics and is also called as pucker fabrics. 15-06-2021 26 7 9 10 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 27. Ornamentation of plain weave fabrics 11) Plain weave is ornamented by using zig – zag reeds to produce wavy effects across the fabric. 12) Plain weave is ornamented in the post loom process like bleaching, dyeing, printing,finishing, raising, etc. 15-06-2021 27 11 12 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 28. Construction of Plain weave 15-06-2021 28 Tie Up R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 29. Warp Rib Regular 15-06-2021 29 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 30. Warp Rib Irregular 15-06-2021 30 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 31. Weft Rib Regular 15-06-2021 31 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 32. Weft Rib Irregular 15-06-2021 32 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 33. Catch cord technique Catch cord technique for weaving Warp rib and Hopsack weaves Catch cord technique is the simplest mechanical device used in handlooms and power looms to weave warp rib weaves and mat weaves. In case of warp rib and mat weaves, it is necessary to weave more than one pick in the same shed. Design ‘A’ is 3 and 3 warp rib weave. In this first, second and third picks are having same interlacement and then fourth, fifth and sixth picks are having same interlacement. This design can not be woven with out catch cord arrangement. It is not possible to weave more than one pick in the same shed unless it is held by the selvedges or some other mechanism like catch cord near selvedges. A Catch cord technique is arranged in the looms, where warp ribs and mat weaves are to be woven. Catch cord arrangement can be either one side or both sides. First pick is inserted in the first shed, and then the successive picks are also in the same shed. It is necessary to hold the first and second picks at the selvedges. Otherwise when second pick is inserted, there will be no second pick instead first pick comes back; hence there will not be any interlacement for first pick and also the successive picks. In the same style first pick is held by the catch cord at the right side, second pick in the left side and the process will continue for any number of picks. Hence, Catch cord arrangement will avoid return of picks in the same shed. 15-06-2021 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM 33

- 34. Arrangement of the Technique Out side the selvedges an extra end (Red) on both sides is drawn through mail eye (harness) or heald wire. This mail eye or heald wire is taken over a pulley arranged on the sley sword as shown in the figure and connected to the picker in shuttle box as in the diagram. When shuttle is not there in box, extra end which meant for holding the pick at outside selvedges, will rest on the race board. If the shuttle enters into the shuttle box, the extra end is lifted up and holds the pick at the selvedges when the shuttle moves. Extra end is through the harness Extra end mail eye or heald mail is connected to picker or to Shuttle not in box the dobby lever / jacquard hook. 15-06-2021 34 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 35. Setting and the working of catch cord The extra end arranged for catch cord (To hold) should touch the race board when the picker is at the front of shuttle box, means when there is no shuttle in the shuttle box. If the shuttle enters the box, picker will move backside of the box and the extra end meant for catch is lifted up. This will help to retain any number of picks in same shed. Similar arrangement on both the sides will help to weave any number of picks in same shed of warp rib and mat weaves. Hence catch cord Technique is very essential to weave warp rib weaves, mat weaves and solid border Sarees/Dhotis. Catch cord technique is largely used in the industry for the weaving of solid border sarees because no additional expenditure. The technique is very much successful for solid border Saree and Dhoti weaving. 15-06-2021 35 Shuttle R.PARANTHAMAN, ASST.PROF., IIHT, SALEM

- 36. Text book and References 1. Grosicki Z. J. “Watson’s Textile Design and Colour: Vo.1, Woodhead Publications, Cambride England, 2004. 2. Grosicki Z. J., “Watson’s Advanced Textile Design and Colour”, Vol.II, Butterworths, London, 1989. REFERENCES: 1. Wilson J., “Handbook of Textile Design”, Textile Instiute, Manchester, 2001. 2. Home C.E., “Geometric Symmetry in Patterns and Tilings” Textile Institute, Manchester, 2000. 3. Seyam A. M. “Structural Design of Woven Fabrics, Theory and Practice” Textile Institute, Manchester, 2002. 4. Geormer D, “Woven Structure and Design, part 1: Single Cloth Construction: WIRA, U.K. 1986. 5. Geomer D, “Woven Structure and Design, Part 2: Compound Structures” WIRA, U.K., 1989 Dr. N. Gokarneshan “Fabric structure and design”, New Age International (P) Limited, Publishers 4835/24, Ansari Road, Daryaganj, New Delhi – 110002. 15-06-2021 R.PARANTHAMAN, ASST.PROF., IIHT, SALEM 36