Dynamic Simulation for HFE & Control System Design Validation

- 1. Dynamic Simulation With Application to HFE and Control System Design Validation info@gses.com

- 2. 2 Nuclear Power Industry Goes Digital • Digital instrumentation and control (I&C) and digital control rooms have become a key focus of the nuclear industry. • New plant designs and the life extension of older plants require the industry and the regulator to understand and validate these system designs and their performance. • Why? To budget and schedule risk, and for safety!

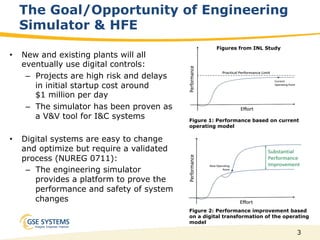

- 3. 3 The Goal/Opportunity of Engineering Simulator & HFE • New and existing plants will all eventually use digital controls: – Projects are high risk and delays in initial startup cost around $1 million per day – The simulator has been proven as a V&V tool for I&C systems • Digital systems are easy to change and optimize but require a validated process (NUREG 0711): – The engineering simulator provides a platform to prove the performance and safety of system changes Figure 2: Performance improvement based on a digital transformation of the operating model Figure 1: Performance based on current operating model Figures from INL Study

- 4. 4 Nuclear Regulatory Guidance • The U.S. NRC reviews the HFE programs of applicants for: – Nuclear power plant construction permits – Operating licenses – Standard design certifications – Combined operating licenses • Detailed design review procedures and guidance for the evaluations is provided in three key documents: – Standard review plan (NUREG-0800) – HFE program review model (NUREG-0711) – Human-system interface design review guidelines (NUREG-0700) – These documents were last revised in 2012

- 5. 5 Nuclear Regulatory Guidance • The NRC is updating its guidance to stay current with recent research on advances in HFE methods and tools, and new technology being employed in plant and control room design. • The purpose of these safety reviews is to help ensure that personnel performance and reliability are appropriately supported.

- 6. 6 How is an Engineering Simulator Different? • Real-time simulators traditionally have been training tools (driven by nuclear industry): – Full plant modeled but computing power limited the fidelity – Models often “hand crafted” to mimic plant dynamics – Basic models adequate for analog controls, traditional hard panel control panels, and “old school” plant process computers • Today’s real-time simulator is high-fidelity: – Same scope, but… – High-definition predictive models used to model plant systems • Engineering-grade models for thermodynamics and neutronics • HD first-principle models used for all other systems • Digital controls and modern digital interfaces provide very detailed view of systems/plant – As a holistic dynamic plant model

- 7. 7 • Holistic engineering V&V platform • Solving system design issue in integrated plant environment • Allow validation of plant system designs in an integrated environment • Allow the validation of systems design in transient and steady state conditions • Controls system design and V&V • Real-time HD simulator provides first holistic view of the plant • Validation and refinement of logic and controls strategies is a key value of simulator • Human factors engineering platform • Support design of DCS interface, alarms, electronic procedures etc.. • Support design of digital control rooms, information layout and CONOPS • Demonstrate viability of these designs to regulator (show me) • Develop and validate operating procedures • Provides the plant buyer a simulator for training & licensing operators earlier in the plant design and construction process Role of the Engineering Simulator

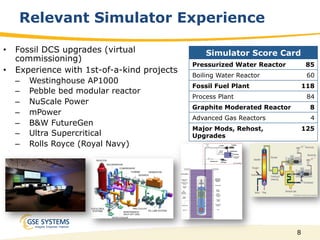

- 8. 8 Relevant Simulator Experience • Fossil DCS upgrades (virtual commissioning) • Experience with 1st-of-a-kind projects – Westinghouse AP1000 – Pebble bed modular reactor – NuScale Power – mPower – B&W FutureGen – Ultra Supercritical – Rolls Royce (Royal Navy) Simulator Score Card Pressurized Water Reactor 85 Boiling Water Reactor 60 Fossil Fuel Plant 118 Process Plant 84 Graphite Moderated Reactor 8 Advanced Gas Reactors 4 Major Mods, Rehost, Upgrades 125

- 9. 9 GSE 1st-of-a-Kind Engineering Simulator Experience Pebble Bed Modular Reactor IGCC China Westinghouse AP1000 NuScale Power Ultra Supercritical Korea SMART Korea Atomic Energy Research Institute HYH CPR-1000 HFE and Control V&V Platfrom B&W mPower Engineering and HFE Simulator

- 10. 10 HFE Simulators • USNRC – Upgrade & convert existing simulator with digital human system interface – RELAP5-HD primary model – Digital control room interface • USNRC – Generic PWR (ANS 3.5 simulator) – Vpanel interface platform – Developing digital HIS • INL – Generic PWR (ANS 3.5 simulator) – NuScale SMR HFE simulator

- 11. 11 More HFE GPWR Simulators • University of Central Florida (under contract to the US NRC) – Orlando, FL USA • Tennessee Valley Authority (Chattanooga State) – Chattanooga, TN USA • Nagoya University (supplied by NEL) – Nagoya, Japan • University of Manchester – Manchester, UK • Halden Reactor Project – Halden, Norway • Ohio State University – Columbus, OH USA • Texas A&M University – College Station, TX USA • Lockheed Martin Corporation – Grand Prairie, TX USA • EDF UK – Gloucester, UK • City University Hong Kong, Kowloon, Hong Kong • University of Virginia (in procurement) – Charlottesville, VA • Center for Advanced Engineering and Research (in procurement) – Forrest, VA USA • Auburn University (in procurement) – Auburn, AL USA” • GSE’s GPWR is based on an actual operating nuclear plant – Thoroughly exercised and validated. – Complete with full documentation including procedures and training materials.

- 12. 1st-of-a-Kind Engineering Simulator Project Perspective

- 13. 13 Example: New SMR (NuScale) • Current NRC requirements do not accommodate the next generation SMR control room designs: • Requirements for large scale reactors need to be evaluated for their appropriateness to SMR operations. • Current requirements interfere with the economic model of some SMRs.

- 14. 14 Background • The dynamic simulator will be the platform for the development and demonstration of this new plant design: – HFE Platform for the new control room design – Control system design and V&V platform – System design validation platform – Marketing tool – Training (critical path to plant operation)

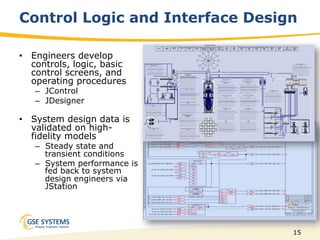

- 15. 15 Control Logic and Interface Design • Engineers develop controls, logic, basic control screens, and operating procedures – JControl – JDesigner • System design data is validated on high- fidelity models – Steady state and transient conditions – System performance is fed back to system design engineers via JStation

- 16. 16 HFE Simulator (Control Room) HFE Simulator 12 Modules plus common systems 12 RELAP5, S3R, etc. 12 operator stations Engineering Simulator 1 Module 1 RELAP5, S3R, stc.

- 17. 17 Westinghouse AP1000 • Project objectives/deliverable – To provide an integrated 1st-Principle high-fidelity simulator models (actual plant is being designed) for: • Human factors engineering (HFE) • I&C/DCS validation & testing (simulated DCS) • Train Westinghouse staff on use of simulation technology • Major Project Achievements – 12 months project schedule (initial phase), on- time delivery – Communication interfaces between SimExec and Ovation DCS – Developed and V&V the plant system models synchronize with plant design schedule • Project Status – Complete all 3 phases of implementation – Building 4 full-scope simulators for Westinghouse • Project Duration – November 2004 to November 2006 17 Initial Control Room Layout Most Recent Control Room Layout

- 18. 18 • Reduce Project Risk – Continuously validate system designs early in design process • Steady state • Validated in integrated and transient conditions – Provide a platform for validation of DCS system – Provide a demonstration platform for regulators and customers of plant operation and safety • Reduce Project Costs – Provide platform for continuous development of control and protection logic strategies on lower cost simulation platform – Flexible lower cost HFE/control room development platform – Delay commitment to a DCS vendor until the sale of the plant, allow customer to choose DCS vendor Engineering Simulator Value

- 19. 19 Engineering Case Study • ConEd Coal Station – Plant initial commissioning – Scheduled for 24 weeks – Simulator purchased prior to plant startup to improve training and operation, but… • As a result of the virtual commissioning of the digital control system: – Startup was reduced by 12 weeks – 84 days of revenue generation was recovered at $500K/day – $42M additional revenue – Simulator cost = $3.8M • This is typical for a these types of projects

- 20. Follow us on: Twitter @GSESystems Facebook.com/GSESystems For more information: Go to: www.GSES.com Call: 800.638.7912 Email: info@gses.com