Kaizen (Continual Improvement)

- 1. TRAINING PT. ENPLAS INDONESIA 2016 by RIYANTO 改善

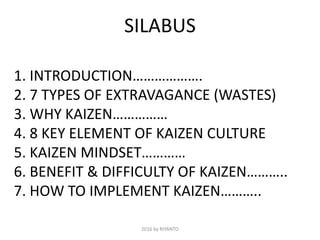

- 2. SILABUS 1. INTRODUCTION………………. 2. 7 TYPES OF EXTRAVAGANCE (WASTES) 3. WHY KAIZEN…………… 4. 8 KEY ELEMENT OF KAIZEN CULTURE 5. KAIZEN MINDSET………… 6. BENEFIT & DIFFICULTY OF KAIZEN……….. 7. HOW TO IMPLEMENT KAIZEN……….. 2016 by RIYANTO

- 3. CHANGE TO BE GOOD 改善 CHANGE FOR BETTER WITH CONTINUAL IMPROVEMENT INTRO 2016 by RIYANTO

- 4. Kaizen, Japanese for "improvement" or "change for the best", refers to philosophy or practices that focus upon continuous improvement of processes in manufacturing, engineering, and business management. It has been applied in healthcare,[7] psychotherapy,[8] life-coaching, government, banking, and other industries. Imai (1986) acknowledged, that Kaizen starts with detection of needs and problem definition: The starting point for improvement is to recognize the need. This comes from recognition of a problem. If no problem is recognized, there is no recognition of the need for improvement. Complacency is the archenemy of KAIZEN.[9] Ishikawa (1985)[10] and Imai (1986) both defined the Seven Basic Tools of Quality. Looking back on the impact of Kaizen, Imai (1997) stated: 'Kaizen' means ongoing improvement involving everybody, without spending much money. When 'Kaizen' was first published here in 1986, many U.S. products were of poor quality, and Japanese-made products were gaining market share. Since then, American companies have made great strides in improving product quality, and much of that is attributable to their implementation of kaizen principles, which incorporate TQM. About KAIZEN 2016 by RIYANTO

- 5. The Father of continuous Improvement 2016 by RIYANTO

- 6. KAIZEN Activity QUALITY IMPROVEMENT REFERS to DEMING CYCLE – Dr EDWARD DEMINGS PDCA is useful anywhere the objective is improved performance 2016 by RIYANTO

- 7. DEMINGS CYCLE or SHEWART CYCLE or PSDA CYCLE found by EDWARDS DEMINGS AND WALTER SHEWART It is a continuous quantity improvement model consisting of a logical sequence of four repetition steps for continuous improvement and learning PLAN ► PLAN AHEAD FOR CHANGE. ANALYSE & PREDICT RESULTS DO ► EXCUTE THE PLAN TAKING SMALL STEPS. STUDY ► CHECK AND STUDY THE RESULTS ACT ► TAKE ACTION TO STANDARDIZE 2016 by RIYANTO

- 10. 2016 by RIYANTO

- 11. 1. To eliminate waste in organization. 2. To increase productivity. 3. To improve quality 4. Customer satisfaction. 5. Growth of the organization. 6. To eliminate any abnormalities & stopping of limits 7. Developing self personality. WHY KAIZEN 2016 by RIYANTO

- 12. KAIZEN MAIN ELEMENT 2016 by RIYANTO

- 13. 1. KAIZEN MINDSET 2. CUSTOMER ORIENTATION 3. QUALITY CONTROL CIRCLES 4. SUGGESTION SYSTEM 5. DISCIPLINE IN WORKPLACE 6. SMALL GROUP ACTIVITIES 7. CO-OPERATIVE RELATIONS 8. TOTAL QUALITY MANAGEMENT. 8 KEY ELEMET OF KAIZEN 2016 by RIYANTO

- 14. 1. EVERYTHING CAN & SHOULD BE IMPROVED 2. NOT A SINGLE DAY SHOULD GO WITHOUT SOME KIND OF IMPROVEMENT. 3. IMAGINE THE IDEAL CUSTOMER EXPERIENCE AND STRIVE TO PROVIDE IT. 4. DON’T JUST CRITICIZE,SUGGEST AN IMPROVEMENT. 5. THINK OF HOW TO IMPROVE IT INSTEAD OF WHY IT CANT. 6. SET TARGET AND MOTIVATE YOURSELF TO ACHIVE IT. 7. USE COMPTETION TO AROUSE INTEREST. 8. DON’T LOOK FOR REWARDS. 9. GENERATE MORE QUESTIONS. 10. SAY YOURSELF I CAN DO IT KAIZEN MINDSET 2016 by RIYANTO

- 15. CUSTOMER ORIENTATION 2016 by RIYANTO

- 16. QUALITY CONTROL SYSTEM 2016 by RIYANTO

- 17. SUGGESTION (STIMULTANT) SYSTEM 2016 by RIYANTO

- 18. DISCIPLINE IN WORKPLACE 2016 by RIYANTO

- 19. Small group Activity 2016 by RIYANTO

- 20. 2016 by RIYANTO

- 21. Total Quality Management 2016 by RIYANTO

- 22. 1. Kaizen reduces waste - like inventory waste, time waste and workers motion. 2. Kaizen improves space utilization and product quality. 3. Results in higher employee moral and job satisfaction. 4. Teaches workers how to solve everyday problems. BENEFIT OF KAIZEN 2016 by RIYANTO

- 23. 1. Resistance to change. 2. Lack of proper procedure to implement. 3. Too much suggestion may lead to confusion and time wastage. 4. Difficult to implement in large scale process, where analyzing requires a lot of time. DIFFICULTY OF KAIZEN 2016 by RIYANTO

- 24. HOW TO IMPLEMENT in MANUFACTURE Employee develops an improvement Idea & discuss with Supervisor Supervisor review this improvement Idea & encourages immediately action Implements By Employee Result PUBLISHES this KAIZEN And reward given This Improvement Written upon a simple KAIZEN SHEET Employee Identify problem, waste or opportunity for improvement and write it down Good Poor 2016 by RIYANTO

- 25. Famous quote “Make everything as simple as possible, but not simpler” -Albert Einstein 2016 by RIYANTO

![Kaizen, Japanese for "improvement" or "change for

the best", refers to philosophy or practices that focus

upon continuous improvement of processes in

manufacturing, engineering, and business

management. It has been applied in healthcare,[7]

psychotherapy,[8] life-coaching, government, banking, and other industries. Imai (1986)

acknowledged, that Kaizen starts with detection of needs and problem definition:

The starting point for improvement is to recognize the need. This comes from recognition of

a problem. If no problem is recognized, there is no recognition of the need for improvement.

Complacency is the archenemy of KAIZEN.[9]

Ishikawa (1985)[10] and Imai (1986) both defined the Seven Basic Tools of Quality. Looking

back on the impact of Kaizen, Imai (1997) stated:

'Kaizen' means ongoing improvement involving everybody, without spending much money.

When 'Kaizen' was first published here in 1986, many U.S. products were of poor quality, and

Japanese-made products were gaining market share. Since then, American companies have

made great strides in improving product quality, and much of that is attributable to their

implementation of kaizen principles, which incorporate TQM.

About KAIZEN

2016 by RIYANTO](https://image.slidesharecdn.com/kaizen-160329070226/85/Kaizen-Continual-Improvement-4-320.jpg)