Kaizen

- 1. KAIZEN PRESENTED BY Robin Saklani MBA 2nd year DOMH NIT Hamirpur

- 2. INTRODUCTION • Masaaki Imai is known as the developer of KAIZEN. • ‘KAI’ means ‘Change or the action to correct’. • ‘ZEN’ means ‘Good’. • Kaizen is small incremental changes made for improving productivity and minimizing wastes.

- 3. MAIN PRINCIPLES OF KAIZEN 1. Consider the process and the results. 2. The need to look at the entire process of the job at hand and to evaluate the job as to the best way to get the job done. 3. Kaizen must be approached in such a way that no one is blamed and that best process is put into place.

- 4. WHAT DOES KAIZEN MEAN? “ KAIZEN STRATEGY IS THE SINGLE MOST IMPORTANT CONCEPT IN JAPANESE MANAGEMENT--THE KEY TO JAPANESE COMPETITIVE SUCCESS. KAIZEN MEANS ‘ONGOING’ IMPROVEMENT INVOLVING EVERYONE—TOP MANAGEMENT, MANAGERS, AND WORKERS.” MASAAKI IMAI

- 5. KAIZEN HISTORY • The history of kaizen begins after World War 2 when Toyota first implemented quality circles in its production process. • This was influenced in part by American business and quality management teachers who visited the country. • This revolutionary concept became very popular in Japan in the 1950s and continues to exist in the form of kaizen groups as well as similar worker participation schemes. • The term kaizen actually became famous around the world through the works of Masaaki Imai.

- 6. KEY PRINCIPLES BASIC PRINCIPLES OF KAIZEN ARE: • TEAMWORK: The team as a whole is better and smarter than the quality sum of the individuals . By teamwork we mean a group of people from different departments within the company working together with a common goal. • DISCIPLINE IN THE WORKPLACE: In an organization discipline is must for everyone. In Kaizen to make sure that the everything work properly discipline is must. • Small group activities. • Co-operative labour – management relations also helps in improvement. • Continuous Quality Improvement is the most important aspect of the Kaizen. • Use of Quality Circles and workers group helps to improve quality of products.

- 7. “5 S” IN KAIZEN 5S MEANING SEIRI Sorting Out SEITON Systematic Arrangement SEISO Spick and Span SEIKETSU Standardizing SHITSUKE Self-Discipline SOME OF THE CONCEPTS INSPIRED BY KAIZEN ARE: The 5 Ss’ stands for the five first letters of these Japanese words.

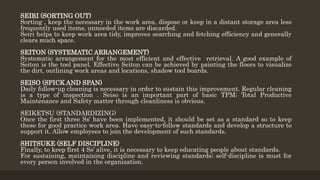

- 8. SEIRI (SORTING OUT) Sorting , keep the necessary in the work area, dispose or keep in a distant storage area less frequently used items, unneeded items are discarded. Seiri helps to keep work area tidy, improves searching and fetching efficiency and generally clears much space. SEITON (SYSTEMATIC ARRANGEMENT) Systematic arrangement for the most efficient and effective retrieval. A good example of Seiton is the tool panel. Effective Seiton can be achieved by painting the floors to visualize the dirt, outlining work areas and locations, shadow tool boards. SEISO (SPICK AND SPAN) Daily follow-up cleaning is necessary in order to sustain this improvement. Regular cleaning is a type of inspection . Seiso is an important part of basic TPM; Total Productive Maintenance and Safety matter through cleanliness is obvious. SEIKETSU (STANDARDIZING) Once the first three Ss’ have been implemented, it should be set as a standard so to keep these for good practice work area. Have easy-to-follow standards and develop a structure to support it. Allow employees to join the development of such standards. SHITSUKE (SELF DISCIPLINE) Finally, to keep first 4 Ss’ alive, it is necessary to keep educating people about standards. For sustaining, maintaining discipline and reviewing standards; self-discipline is must for every person involved in the organization.

- 9. QUALITY CIRCLES • The concept of Quality Circle was developed in Japan in 1962 and it quickly became popular and spread to more than 35 companies in the first year. • A Quality circle is a small group of employees in the similar work area who voluntarily meet regularly and whose assignment is to identify the problems related to quality improvement, formulate solutions and present their results to management with suggestions for implementations. • This improves the performance of the organization, while also motivating and enriching the work of employees. • This naturally produces an environment where operators are continually looking for solutions to problems, with greater involvement. • In India quality circles first initiated in an engineering company Bharat Heavy Electrical Limited (BHEL).

- 10. KAIZEN EVENT • In modern usage, kaizen is designed to address a particular issue over the course of a week, which is referred to as a “kaizen blitz” or “kaizen event”. • A kaizen event is a focused development project that can accomplish breakthrough improvements in a short amount of time, about 2-10 days in scope. • Kaizen events must have a clear, concise objective along with immediately available resources and rapid results. This ensures the results are significant, clear and quick to promote the generation of continued enthusiasm and satisfaction

- 11. 10 PRINCIPLES OF KAIZEN The Kaizen method follows ten specific principles, which are described below: 1. Improve everything continuously. 2. Abolish old, traditional concepts. 3. Accept no excuses and make things happen. 4. Say no to the status quo of implementing new methods and assuming they will work. 5. If something is wrong, correct it. 6. Empower everyone to take part in problem solving. 7. Get information and opinions from multiple people. 8. Before making decisions, ask “why” five times to get to the root cause. (5 Why Method) 9. Be economical . Save money through small improvements and spend the saved money on further improvements. 10. Remember that improvement has no limits. Never stop trying to improve.

- 13. THE SEVEN WASTES (MUDA) 1. DELAY, WAITING OR TIME SPENT IN A QUEUE WITH NO VALUE BEING ADDED. A large part of an individual product’s life is spent waiting to be worked on. 2. PRODUCING MORE THAN YOU NEED. It leads to excess inventory, which then requires the expenditure of resources on storage space and preservation. 3. OVER PROCESSING OR UNDERTAKING NON-VALUE ADDED ACTIVITY. Over processing occurs when more work is performed on a piece than what is required by the customer. 4. TRANSPORTATION. Each time a product is moved, it stands the risk of being damaged, lost, delayed, etc. as well as being a cost for no added value. 5. UNNECESSARY MOVEMENT OR MOTION. Motion refers to the damage that the production process inflicts on the entity that creates the product. This may be either over time (wear and tear for equipment and repetitive strain injuries for workers) or during discrete events (accidents that damage equipment and/or injure workers). 6. INVENTORY. Whether it is in the form of raw materials, work-in-progress, or finished goods, represents a capital outlay that has not yet produced an income, either by the producer or for the consumer. 7. PRODUCTION OF DEFECTS. Defects cause extra costs for reworking the part and can sometimes result in doubling the cost of one single product.

- 14. BENEFITS OF KAIZEN • KAIZEN REDUCES WASTE: In areas such as employee skills, waiting times, transportation, worker motion, over production, excess inventory, quality and in process. • It improves product quality, use of capital, production capacity, communications , Space utilization and employee retention. • Kaizen provides immediate results. Instead off focusing large scale improvements, which involve capital intensive, Kaizen focuses on creative investments that continually solve large number of small problems. • A LEARNING EXPERIENCE: Every member of a Kaizen Team will walk away from the event learning something new • . • The real power of Kaizen is in the on-going process of continually making small improvements that improve processes and reduce waste. It also encourages big picture thinking. • Results in higher employee morale and job satisfaction.

- 15. CASE STUDY ON IMPLEMNTATION OF KAIZEN IN KIRLOSKAR COPELAND LIMITED

- 17. • Kirloskar Copeland LTD is a joint venture between Kirloskar Brothers Ltd and Copeland USA . • KCL manufactures a range of air conditioning and refrigeration compressors. • KCL boasts clients such as BLUESTAR ,CARRIER, and VOLTAS. • KCL has two plants one at Atit and other At Karad ,Pune. • KCL introduced the Kaizen at Atit and Karad plants in 1997.

- 18. • Kaizen introduced for permanent employees and later embracing contract workers too. • Kaizen awards are introduced for employees and vary from steel tumblers ,clocks for individual achievers to field trips for teams. • A worker having 80 improvements to credit gets to go on a training course to Copeland s mother plant in US. • An operator at the Atit plant , S. L Kalbhor , is first with 80 plus kaizens and sent to US. • In US he intends to study how they ensure zero rejection , and help implement it here.

- 20. • Among the achievements he is particularly proud of are ; • Introduction of ink bottle within the cycle to automatically put dot on each compressor when its oil is changed . • A safety device to stop conveyor belt when sheer pin breaks. • A slide fixture so that the operator does not burn his hands lifting down dehydrating compressor.

- 21. • As a result of Kaizen the set up change time is brought down from 30 min to 8 minutes . • Rejections are reduced drastically . • One particular kaizen implementation in an operation resulted in increase in per shift output from 175 to 225 compressors. • Introduction of Kaizen in SEP 1997 set up the trajectory of growth for Kirolskar. • KCL has achieved an average of three kaizens per employee per year and it wants to increase to six and also extent practice to ancillary suppliers.

- 23. THANK YOU Have a Nice Day