មេកានិកនៃសន្ទនីយ៍

- 1. CMBUkTI1 Chapter 1 I-lkVN³TUeTAGeneral I-1-1-niymn½yrbs;vtßúravDefinition of fluid vtßúravmancrwkeRcInya:gKÅ : k¦ CarUbFatuEdlfitenAeRkamTMrg;Caliquid nig Solid x¦ vtßúrav KWCarUbFatuEdlmankarERbRbYlTMrg;kñúgkrNImanGMeBIBIxageRkA . eKehAfa karcl½trbs;PaKl¥iténvtßúrav (Particulars of fluid) . K¦kMLaMgxageRkAGacbNþalbegþIteGaymanCaclnarbs; fluid tamTisedAénkMLaMg . X¦eKkMNt;tamlkVN³mCÄd§anénkarxUcRTg;RTay nig mCÄd§anénkareFVIbnþ. g¦vtßúrav KWmanrUbragdUcmCÄd§anénkareFVIbnþ EdlbgðajGMBITMrg;m:UelKulrbs;rUbFatuedayKit bBa¢ÚlTaMgemKuN nig smIkar constitutive . c¦ eKEckCavtßúrav nig hÁas . ]TarhN_ ³ TwkCa fluid incompressible. hÁasCa]s½μncompressible. CaTUeTAeKkMNt;famanBIrsarxarbs;mecanic of fluid KW a) DINamiuc én vtßúrav b¤ Hydrodynamic. b) DINamiuc én haÁs b¤ Aerodynamic. q¦ TMrgrbs;vtßúravKWmaneTAtamTMrrbs;eRKOgRTehIyépÞb:HCamYybriyakasvaCaépÞesrI (Face Free). I-1-2-niymn½yrbs;GuIRdUDINamic Hydrodynamic - sikSaeTAelIclnarbs; vtßúrav KWCamCÄd§anénkareFVIbnþ EdlTak;TgeTAnigrMhUrrbs; vtßúrav nigRbsiTi§PaB epSg²eTotrbs;va . - hÁasKWsikSaGMBIrMhUr]s½μnepSg ² - emkanic énvtßúrav nig emkanic én vtßúrWg solidmansarsMxan;epSgKña² .

- 2. emkanic én vtßúravMechanic of Fliud emkanic én vtßúrav (EdlmanCatiTwk, ]sμ½n) emkanic énvtßú rwg GIuRdUDINamiuc GaeGrU:DINamiuc Hydrodynamic Aerodynamic I-1-3-RbePTénrMhUr Type flow k¦ rMhUrrbs; vtßúrav Caclna Continue . x¦ cMeBaH vtßú rWg bnøas;bþÚrCabøúk . K¦ rMhUrrbs; vtßúrav manlkVN³Cael,Ón edaykMlaMgsm<aFniglkVN³epSgeTot dUcCadg;sIuet nig Viscosity . X¦ Viscosity KWCargVas;er:sIusþg; én vtßúrav rbs;rMhUrehIyKWCalkVN³kkitrvag clnaPaKl¥it . c¦ Hydrodynamic KWCa Hydrostatic KWsikSavtßúravenAhñwgmYykEnøg. q¦ rMhUr vtßúrav Bit KWCa Laminar ( rMhUrrbs;vamanlkVN³CaRsTab;²) C¦ cMeBaHrMhUr Turbulent CarMhUrxñÚlxñaj;. Q¦ rMhUurÉksNñan Uniform KW g = 0 ehIyviucT½r el,Ón Velocity RsbKñaRKb;cMNuc . j¦ rMhUurCaTUeTAmanEbkCa x , y , z EdlmaneQñaHehAfa Tridimensionnel. RbsinebIrMhUrmanEt BIrmuxRBYj KWCarMhUr Bidimensionnel b¤ Plan. EtebImanEtmYypøÚvrMhUrenHehAfa Unidimensionnel . I-2- c,ab;rkSaTukénkMlaMg Laws of conservation 1-kMmøaMgmanEckCaBIrKW ³ – kMmøaMgekItedayTMnajEpndI Gravitational constant (g = 9.81m/s² ) –. kMmøaMgekItedaykarkkit nig sm<aF 2- kMmøaMgenHmanTMnak;TMngCamYy cMnYnerNul Reynolds (Re) KWmankMmøaMgniclPaB nigkMmøaMg sm<aF. 3-kñúgkarGnuvtþ eKman c,ab;rkSaTukénkMlaMgsMrab;sersrGMBIclna én vtßúrav. i) c,ab;rkSaTukénm:as;tameKalkarRKwH én Continuity ii ) c,ab;rkSaTukénbrimaNclnatameKalkarRKwH énm:Umg;( dynamic)

- 3. iii ) c,ab;rkSaTukénfamBl( eKalkarRKwH thermodynamic ) I-3- TMhM nig xñat Dimensions&Unit 1-bNþay ( L) 2-ry³eBl ( t ) 3-ma:s; ( m ) 4- sIutuNðPaB ( t , ˚K ) i) kmøaMgForce in pounds = ma:s; mass in slugs ( m ) x acceleration TMnajEpndI ( g ) SI = kmøaMg ( jÚtun ) ii) ma:smaD = = 3 m Kg V M iii) kmμnþ ( T ) =F x cMgay ( L ) =( Nm ) b¤ ( j ) hSÚl I-4-1 Fluid Properties 1) Density V m ; 3 m Kg 2) Tm¶n;maD Specific Weight g ( N/m³ ) , 3 m N V M 3) maDykSfaRbePT Specific Volume ( SV ) , 1 SV ; Kg m3 4) dg;sIuetyfaRbePT Relative density( RD) eau RD ( Pa = 1 atm , T = 3.98 ˚C ) 5) BIsáÚEm:Rt Pycnometer eRbIsMras;KNnarkrTMng;maD V ww 12 1W , 2W Tm¶n;rbs;vtþúrav 1V , maDrbs;vtþúrav 6) GIuRdUEm:Rt Hydrometer 2 1 12 l l (rUb a ) 1 = ma:smaDEdlsÁal; 2 = ma:smaDminsÁal; N T ML 2

- 4. 7) GIuRCUEm:Rt Hydrometer eRbIsMras;eKalkar d’Archimètre

- 6. I-4-1- Viscosity of Fluid 1-KWCargVas;ersIusþg;énrMhUrrbs;Fluid DIya:Rkaménel<ÓnrMhUr A dz du & ( A F ) ; Shear Stress μ - Dynamic Viscosity Pas dz du ; dYdV = rStrainRateofShea sShearStres kñúgkrNIEdlμ = 0 or u = 0 Ca(ideal fluid );μ ≠ 0 Ca(Normal fluid). 2- Kinematic Viscosity s m2 Dencity 1poise = 1 g / cm .s s m2 Stokes (St) = 1 cm² / s i) Viscosimetre visáÚsIuEm:Rt én bMBg; ii) Viscosimetre rotatif visáÚsIuEm:Rt vil

- 7. 3- sm<aFcMhay Vapor Pressure krNI énqñMagEdlbitCit rYcdak;TwkTukeGayBuH eKsegáteXIjmancMhay TwkehIreLIg maneQμaH ehAfa sm<aFcMhayTwk . 4-tg;süúgyfaRbePT Surface tension m:UelKkulrbs;vaEdlekItmanenAkñúgTwkeRkamGMBIénkMLaMgkRnþak;skmμRKb;TisTI . L F sigma ; J/m2 m N m2 ΔF kMLMagénPaByItEdlEtg RKb;sarFatu ΔL CaRkLaépÞénTwk. 5- kaBILarIet Capillilarity KWbNþalmkBI surface tension nigGaRs½yedayPaBsi¥tCab; ( adhésion ),kMLaMsi¥tCab; ( Cohésion ) . bMBg;EdlykmkeRbI Ø=10mm rgr h cos..2cos..2 qñaMgdutkMedA cMhayTwk Twk ²=2

- 8. h - kMBs;TwkeLIg ( depression ) - Surface tension -mMulMgakWetting angle dihtofliquiSpecificWe r-kaMén bMBg;Radius of tube ( mm ) 6-m:UDuleGLasIÞk ( E ) Bulk Modulus of Elasticity v dv dp E ( Pa ) b¤ (bar = 5 10 pa= 5 10 N/m2 ) 1atm = 1.013bar = 760mmHg dp- bMErbMrYlénsm<aF - v dv -bMErbMrYlénmaD 7-lkçN½ én Isothermal Conditions RbsinebIsItuNðPaBefrenaHvamankarbMElgBIcMNuc 1 2 tamc,ab;hÁas 2211 vPvP nig 2 2 2 1 P efr tamlT§plE = P 8-Isentropic Condition kk vPvP 2211 , 2 1 2 1 const , E= K . p k – plepobénma:srbs;kMedA ( Cp ) efrCamYymasmaDénkMedA 9- vibtþ½n½ysm<aF Pressure disturbances KWvaTak;TgeTAnigbmøas;TIénvtþúravnigkarekIneLIgénel,Ón EC k k P P T T 1 1 2 1 2

- 9. sMrab;hÁas Acoustic Velocity RTgK K C p .. 10- sItuNðPaB Temperature T(K) = T(o C) +273.16 (Kelvin) ; o R = o F + 459.69 (Rankine) tamTMnak;TMngrvag Temperature, Pressure, Volume, density én Constant mass of gas ( Considred Perfect or ideal ) Gnuvtþn¾tamrUbmnþ: 2 22 1 11 T Vp T Vp ; pV = mRT ; p = RT and M R 8314 Edl p = Pressure( Pa) V = Volume (m3 ) T = Temperaturein K m = mass of the gas in Kg = density of gas in Kg/m3 R = gaz constant ( J/Kg.K) M = Relative molecular mass of the gas (no unit) T = 200 C ; = 13.580 Kg/m3 (Mercury) = 0.0838 Kg/m3 (Hydrogen) = 1000 Kg/m3 ;(H2O) 11- mrimaNFarTwkVolume flow rate(Q; . V ) . V = A.V (m3 /s = m/s x m2 ); 12- Mass flow rate ( . m ) . m = . V = v.A. ( Kg/s = m/s x m2 x Kg/m3 ) 13- Continuity equation tConsmm outin tan .. V1 .A1. 1 = V2 .A2. 2 tConsVV outin tan .. v1 A1 = v2 A2 Fluid flow through a system

- 10. taragxñat eQμaH nimitþsBØa xññatSI xñatRKiHSI TMnajEpndI ( g) m/s2 ma;:s;maD ( ρ) Kg/m3 kMlaMg;TMgn;maD;PaBF¶n; ( F) N Kgm/s2 TMng;yfaRbePT ( γ) N/m3 Kg/m2 s2 sm<aF;kugRtaMg; ;PaByIt (P;τ;E) Pa N/m2 Kg/m s2 famBl;kmnþ ( E;Work) J Nm Kgm2 /s2 GnuPaB (Hp) W J/s Kgm2 /s3 vIsáÚsIuetDINamiuc (μ) Pa.s Ns/m2 Kg/ms vIsáÚsIuenTic (ν) m2 /S Ns/m2 Kg/ms RkLaépÞ (S) m2 vUlUm (V) m3 elÇIn (v) m/s cMNaM 1Kgf = 9.81 N ≈ 10N; 1tf = 9810N ≈ 10N; 1gf = 9,81.10-3 N ≈ 10mN; 1Kgf/cm2 = 98100 Pa ≈ 100 K Pa ≈ 10-1 MPa; 1Kgfm = 9,81 J ≈ 10J; 1tfm = 9810 J ≈ 10KJ; 1cv(1esH) = 735,5Wt; 1t = 1000Kg; 1l/s = 10-3 m3 /s ; 1P (poise) = 10-1 Pas; 1St (Stokes) = 10-4 m2 /s; ρH2O t = 00 C : ρ = 999,841 Kg/m3 ; ρH2O t = 40 C : ρ = 999,973 Kg/m3 ; ρH2O t = 100 C : ρ = 999,900 Kg/m3 ; ρH2O t = 200 C : ρ = 998,203 Kg/m3 ;

- 12. Chapter 2 Statique des fluides Fluid of Statics 1-Unit pressure or pressure k¦ RbsinebIeKmanRBIsragCaRtIekaNénTwkEdlmanmYyxñatTTwgén Twks¶b;tam TMnak;TMnggéometrique ¬FrNImaRt ¦ . dx = ds.cosθ ; dz = ds.cosθ x¦ Tm¶n;rbs; fluid EdlbnþénRBwsKW 1. 2 dx dz g K¦ sm<aF ( P ) KWCabrimaNsáaélénkmaøMgsm<aF F . GaMgtg;sIuetkmøaMgsm<aF ³ P1( dz.1 ) , P 2( dx .1 ) nig P3 ( ds.1 ) X¦ lkçN½ÐlMnwgén force hydrostatique i¦ kñúgTisedAedk P1.dz – P3.ds .conθ = 0 tamTMnak;TMngFrNImaRt P1 = P3 ii¦kñúgTisedAbBaÆr 0cos. 2 32 dsPdxPdx dz g Edl gdzPP 2 1 32 RbsinebI dz0 P2 = P3 g¦ P1 = P2 = P3 ¬sMrab; fluide au repos ¦ c¦ pdsF s b£ ds dF p CaGaMgtg;sIueténsm<aFEdlman F nig RkLaépÞ S . 2- smIkarHydrostatique k¦ CadMbUgkñúgTisedA Z , x , y x¦ ebIsinmanbMBg;Twkminbmøas;TI kmøaMgEdlmanGMeBIeTAelImaD i ¦ kmøaMgmaD dsdzz ii¦ kmøaMgRkLaépÞ Pds nig dsdz z p P

- 13. iii¦ kmøaMglMnig én Z 0. dsdzzdsdz z p ppds Edl 0 z z p iiii¦ eKGacsresr)an smIkarlM nwg 0 0 0 z p z y p y x p x b¤ 0. pgradf iiiii¦ kmøaMgmaDénmaDmYyxañt + kmøaMgsm<aFénmYymaDxañt iiiiii¦ CaviucT½rénkMlaMgmaD ( x , y , z ) g = 9,81 m/s2 iiiiiii¦ smIkar g z p y p x p 0 0 iiiiiiii¦ tamsmtikmμ k¦tamTisedA x 0 x p ; P = Cte x¦tamTisedA y 0 y p ; P = Cte K¦ g z p g dz dp pgrad f f gz y x f 0 0

- 14. 3- bMErbMrYlbBaÄrénsm<aF I) fluide incompressible fluide minbMENn)an 1)- 2121 zzgpp 2)- kñúgkrNIEdlma:smaDén fluide efr eK)an³ Ctezgp tamlk§N³eRhVkg; Ctezgpp p efr eTAtamcm¶aybBaÄr Z ehIysm<aF P fy cuH p famBlb:Utg;Esül ( m ) g TMnajEpndI m/ s2 g p bnÞúkBIeysUemRTIk vamantémøefrcMeBaH fluide repos . 4- sm<aFdac;xat , sm<aFrWLaTIv Pression absolue -kñúgkrNIsm<asbriyakas eKehAva fa Pa rIÉCMerATwkvijKWCa Za 1 ' 1 ZZgPP aa Et Za – Z1 = h ghPaP ' 1 CargVas;eFobCamYybøg;erehVr:g( 0.0) suBaØakasdac;xat ( Pa = 105 Pa ) . ' 1P = Casm<aFdac;xat -kñúgkarGnuvtþn_ ghP 1 Casm<aF rWLaTIv ( Pression refative) . ehIysm<aFdac;xat 1 ' 1 PPaP 5- Fluide Compressible ¬vtÚßravGacbMENn)an¦ Const KWvaTak;TageTA P , t0 rbs; fluide parfait . RT P ' P’ = sm<aFdac;xat R = PaBefrénsItuNðPaBrbs;hÁas Parfait

- 15. T = sItuNðPaBdac;xat TR p g dz dp . ' cMeBaHvavtßúravIsotherme KWCakarERbRbYl xdp d x - emKuN compressible isotherme x = 5 . 10-10 Pa ‘ bMErbMrYlénsm<aFsMrab; liquide compressible rxpg dz d 10 Pr = sm<aFrWLaTIvedayeFobsm<aFerehVr:gPo . 0 6- vgVas;sm<aF Mesure de Pression 1-xñatsm<aF 2 m N S F P b£ F = kmøaMg S = RkLaépÞrag cMNaM ³ 1bar = 105 Pa = 106 bayers Pa m kgf 81,9 1 2 mm m kgf 1 1 2 C.e 2-sm<aFbriyakas eFobnIvUrbs;smuRT eKeXIjkMBs;)aet 760mm sm<aF P = 1.013 Pa xül; = 1.225 kg / m³ RtUvsItuNðPaB T = 15 0 C b£ 288 0 k 3-]bkrN_vas;sm<aFbriyakas 3 42.133 m kn hg , sm<aFcMhay Pv = 0 Pression Z2 – Z1 = 760 mm C.e attmosphérique

- 16. - Baromètre anéroide )ar:UEm:RtGaeNr:UGIut - ]bkrN_vas;;sm<aFrWLaTIv( Pression relative ) 111 hP sm<aFrWLaTIv 11 ' 1 hPP a sm<aFdac;xat - ma:NUEm:Rt( Manonètre) eRbIkñúgbMBg;rag U Edlman 2 m ¬rbs;rlay ¦ 2222 lhP m sm<aFrelative 222 ' 2 lhPP ma P2 nig P’ 2 maneRbIedayvas; h1 nigl2 emIltamRkit m nig 2 CacMnYnmFüménHydromèter Pa sm<aFbriyakas 34443 . lhlPP mm

- 17. h 1h 0P ghP 0 l4 , l 3 , Δh ( m ) 43 ,, m Tm¶n;maDénvtßúrav -ma:NUEm:Rtbr½dug vide vism<aF KWCaPaBxusKaμ énsm<aFvas;eXIj nig sm<aFbrikal ]-sm<aFvas;kñúgma:sIunbUmTwkman 0,690 bar ehIysm<aFbriyakas xageRkAman 1,013bar dUecñH vide KW 1,013bar – 0,690 = 0.323 bar cMNaM ³ P1 – P2 PaBxusKañésm<aF A F P , g hP . , 3 m N Pap h 7- sm<aFénépÞesrI (Pression vide) const s p gz smIkarRKwH Hydrostatique -sm<aFdac;xatPression absolue nigsm<aFdac;xatPression Manamètreque suBaØakasPression vide . k¦smIkarRKwH 0 0 p gz s p gz 10 ghP

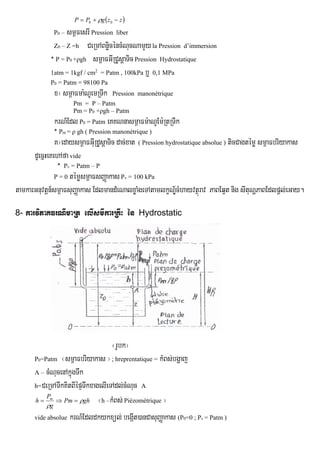

- 18. zzgPP 00 P0 – sm<FesrI Pression liber Z0 – Z =h CeRmABnøicéncMNucNamYyla Pression d’immersion ٭ P = P0 +ρgh sm<aFGIRCUsþaTicPression Hydrostatique 1atm = 1kgf / cm2 = Patm , 100kPa b¤ 0,1 MPa P0 = Patm = 98100 Pa x¦ sm<aFma:NUemRTIk Pression manonétrique Pm = P – Patm Pm = P0 +ρgh – Patm krN_Edl P0 = Patm eKKNnasm<aFm:aNUEm:RtRTIk ٭ Pm = ρ gh ( Pression manonétrique ) K¦edaysm<aFGIuRdUsþaTic dac;xat ( Pression hydrostatique absolue ) ticCagtémø sm<aFbriyakas dUecñHeKehAfa vide ٭ Pv = Patm – P P = 0 témøsm<aFsBaØakasPv = 100 kPa tamkarGnuvtþn_sm<aFsuBaØakas EdlmandMeNalxøaMgeTAtamlkçNнcMhayvtßúrav PaBEq¥t nig sItuNðPaBEdlpþl;eGay. 8- karviPaKFrNImaRt elIsmIkarRKwH én Hydrostatic ¬rUbk¦ P0=Patm ¬sm<aFbriyakas ¦; hreprentatique = kMBs;bgðaj A – cMNucenAkñúgTwk h=CeRmATwkKitBIépÞTwkxagelIeTAdl;cMNuc A ghPm g P h m ¬h –kMBs; Piézométrique ¦ vide absolue krN_Edldkykxül; begáIt)anCasuBaØakas (P0=0 ; Pv = Patm )

- 19. h = 10m ¬ KWKitBInIvU Piézométre cMhrnigbitCit ¦ cMeBaHkrN_ ³ PatmP 0 bgðajfa h g Pm ¬rUbx ¦ PatmP 0 bgðajfa h g Pv g P g PatmP hPatmghP r 0 0 hH = Charge hydrostatique = g P Z 9- RkahVik én sm<aF Représentation graphique de la pression ghPP 0 Pression hydrostatique kñúgkrN_CaeRmATwk Rtg;BIrcMNucxusKμa eKsresr ³ 2 1 2 1 2 1 2 1 h h P P ghP ghP m m m m

- 20. 10- c,ab;cr én TwkkñúgepIg Loi des vases communicants 220110 hPPghP 1 2 2 1 h h 11-eKalkarN_c,ab; Pascal ¬ sm<aFGuIRCÚlik ¦ Principe de Pascal , Presse hydraulique oP -sm<aFenAxageRkA EdlCaGnuKmn_én h b a PP o 1 b a P P O 1 -muxkat; énBIsþúg EdlmanGgát;p©wt d ; =muxkat;BIsþúg Ggát;p©wt FM .. b a PpP o -cMnYnbBa¢Úa b¤ 2 d D edayKitGMBIfamBl EdlmanTMnak;TMngeTAgÉ 2 : d D b a PP o 80,0 eTA 0,80 kM/lMelIkTMenIb 700.00KN .

- 21. Chapter 3 kmøaMgsm<aFénvtßúravEdlmanGMeBIelIépÞ Force de la pression hydrostatique sur une surface plane horizontale Hydrostatic Forces on Plane Surfaces I- Hydrostatic Absolute Pressure (Pabs) eKdwgfasm<aFdac;xatGIuRdUsþaTic ( Pression hydrostatique absolue ) KW ghPatmPabs b¤ ghPPabs 0 (Pa) Etsm<aFenHmanGMeBIelIRkLaépÞ én)atGag (ω) dUecñHeKGacsresr)an ³ .' absabs PP (Pa) eday Pabs ³ sm<aFGIuRCUsþaTicdac;xat ω ³ RKLaépÞ)at (m2 ) ghPP abs 0 ' edIm,IgayRsYl KWeKsresr P= ρghω II-kmøaMgsm<aFelIRkLaépÞénbøg; Mgnitude of Resultant Hydrostatic Force (Force de pression sur les surfaces planes à orientation arbitaire) RKb;cMNucTMagGs;Edlsm<aFxus²Kañ KWvaCaGnuKmn_énCeRmATwklkVN³enHekItman cMeBaHbøg;bBa¢it . ehIykar Gnuvtßn_xusKμaBIrYmbnþ xagelI . edayKitBImMulMgak α dUecñHeKGacsresr)an dghPdPdP 0 edaybUkbBa¢ÚalkMLMagmYyEpñkeTotEdlRsbCamYyenaHKW ..0 cgghPPa ; (Pa) hcg –kMBs;TwkRtg;cMNucTIRbCMuTmøn; . eday Po = Patm ; dUcenH P = ρghc.g.ω Pressure gauge ¬ sm<aFm:aNUemRtIk¦

- 22. III- TIRbCMuTm¢n;énsm<aF Centre de Pression (Center of buoyancy) Center Pressure KWCacMNuccab;énkMLMagenAEpñkkNþalénkMeNInrbs;kMLMagsm<aF elIépÞ. lcp- RbEvgénTIRbCMusm<aFxageRkam (m) lcg – RbEvgénTIRbCMuTm¶n; (m) hcg – CeRmATwkRtg;TIRbCMuTm¶n; (m) hcp –CeRmATwkRtg;TIRbCMusm<aF (m) eKsresr P.lcp =∫ωdp.L cg x cp l J l ω-RkLaépÞénbnÞH(m²) jx – m:Um:g;niclPaBeFobnigépÞ TwkxagelI. j0 – m:Um:g;niclPaBeFobnigGkSRsb TIRbCMuTm¶n;. 2 cgox ljj

- 23. cg o cgcp l j ll IV- KNnaRkahVikénkMLaMgsm<aF nig TIRbCMuTm¶n;énsm<aFelIbøg;ragctuekaNEkg Détermination graphoanalytique de la force de pression et du centre de pression sur les surfaces rectangulaires planes maDénDIya:Rkamsm<aF blghWéq .. 2 1 kMLaMgsm<aF bl h gghP cg . 2 .. eK)anl = h kMBs;Twk (m) b – TTwgbnÞHCBa¢Mag V- sm<aFkMLaMg énvtßúrav elIRkLaépÞekag Hydrostatic Forces on Curved Surface. Force de pression du liquide sur les surfaces courbes manvtßúmYyxagABC . BC CaRBMRbTl;. Pz kMLMagbBaÄrEdlGMeBIelIcuHeRkamedayqøgkat;tamTIRbCMu Tm¶n;ABC .

- 24. Pz CakMLaMgEdlbukBIeRkameLIgelItamTIRbCMuTm¶n;0 Pz c) Pz d) Pz ` force de pression ragsIuLaMgKW 22 zx PPP CaTUeTAPx = 0 ; Py =ρghcgωy rUbmnþTUeTAénkMLaMgsm<aF 222 zyx PPPP VI- viFIKNnaTwsedAénkMLaMgsm<aFEdlmanGMBIelIbnÞHva:n b h gP 2 2 ebIn CacMnYnsm<aFb¤bnÞHva:ndUecñH b n gh n P 2 2 b-TTwgTVarTwk rYccMgayBIépÞTwkxagelIrhUtdl;TIRbCMuTm¶n; D KW hlp 3 2 b¤ 11 3 2 hlp b¤ i ii ihl ipi 11 3 2 222 aah n i hi

- 28. Chapter 4 vtßúGENþtkñúgTwk Flottement des corps dans un liquide Stability of floating bodies I- eKalkarN_RKwHéndMeNaldasIuEm:Rt Poussée d’ARCHIMED eKEckrUbFatuCaBIrKW ABC EpñkxagelInig ADC EpñkxageRkam . ehIyvtßúFatuTMagenHfitenA eRkamkMLMagbBaÄr. eKsresr)an ³ 11 gwPz , 22 gwPz EdlmanmaD AEFCB , AEFCD tampldkcinmaD eK)an maD ABCD gwWWgPPP zzz 1212 dUecñH eKGacsresr P=ρgw Neutral Stable Floating a). G>P G =le poids d’un corps Wightof the body Tm¶n;rUbFatu P = la poussé verticale Bouyaancy Force dMeNalénkMlaMgbBaÄr

- 29. w- maDvtßúravEdlpøas;TItamvtßúFatumaneQμaHehAfa maDénkaEv:n ( Volume Carene ) D- TIRbCMUTm¶n;énmaD . edaykMlaMgbBaÄr kat;tam D maneQμaH ehAfasg;dWkaErn ( Centre de Caréne ) . C-TIRbCMuTm¶n; Centre of gravity . tamlkV½NGENþt G = P = ρgw II )- lkVN³lMnigvtßúGENþt Stabilité des corps flottants stable lMnig Instable KμanlMnig Stability of floating bodies

- 30. Stability of floating bodies XøIgeXøagtic stable δ < r Instable δ >r Stability of Partially Submerged Bodies. α- AnglemMulMgak <150 , D’ - cMNucEd½lGkS½bBaÄr D’ P - xN³QIøgeXøag M-cMNucemtas½g;RTIk ( Meta centric Height ) . D- sg;;énkaErn G- TIRbCMuTm¶n; . r- kaM emtasg; (Meta centric Height) ; б – PaBenAq¶ayBImCÄmNÐl excentricité m-cMgayMeta centric Height m = 0,3 eTA 1,2 1)krNI r <б KμanlMnig instable . 2) б<r lMnIgstable r = J0 / w J0 m:Um:gniclPaB ; w maDénkaEv:n r / б>1

- 31. Chapter 5 RbePTrMhUrénvtßúrav nig smIkarEb‘rnuyI Type découlement du liqude et equation de Bernoulli GIuRdUDINamiucKWsikSaGMBIclnaemkanicénvtßúrav . ehIyrMhUrrbs;clnaTwkKWvaTak;TgeTAnig ÷ 1-kM / lMsm<aF nig kM/ lMkkitxagkñúg 2-kM/lMTIRbCMuTm¶n; . rMhUrénclnaTwkmanEckecjCaBIrya:gKW ÷ k ¦rMhUrGnaciéRnþ ³ KWcariklkVNHtamcMNucnimYy²EdlrMhUrénel,Ón nigsm<aFERbRbYlGaRs½ytam eBlevlat . x¦ rMhUrGniéRnþ ³ KWCarMhUrEdlel,ÓnminERbRbYltameBlevla. rMhUrenHEbgEcgCaBIreTotKW - rMhUrÉksNæan ³ el,Ón nig épÞxñat;rbs;crnþminERbRbYleTAtamRbEvgbeNþayRClg . I.CMralGIuRCUlIk II.CMral)atRbLay b.rMhUrminÉksNæan³ el,ÓnnigépÞxñat;rbs;crnþéRbRbYleTAtamxñatbeNþaénRClg. cMNaM ³ rMhUrenHERbRbYlCanic© . c.rMhUr ³ rMhUrrbs;vtßúragmanEckCarMhUresrInigrMhUredaybnÞúk > rMhUresrI ³ RbLay , swÞg , ERBk , bMBg;lUredayKμanbnÞúk >rMhUrmanbnÞúk ³ TwkhUrkñúg bMBg;Edlmansm<aFCYyrujbEnþm . * ExSéncrnþ nig)ac;éncrnþ

- 32. * carwklkVNHGIuRCUlicénxñatcrnþrbs;FarTwk nig el,ÓnmFümenAkñúgGIuRCUlicmancarwklkVNHdUcteTA ÷ hmhbS )1 2 12)2 mhbP 30-R kaMGIuRCUlic P S R S-épÞxñat;rMbUar P-brimaRtesIm -cMeBaHbMBg;vij 4 d R ¬ d Ggát;pwt ¦ -el,ÓnmFüm s m v Q v Q=ω. v ( m³ s ) - sMrab;rMhUresrICael,ÓnenARtg;cMNc; 0.6 h . cab;BIépÞTwkcuHeRkam . - sMrab;rMhUredaybnÞúkCael,ÓnenARtg;cMNuc - 0.223 r KitCasMbkbMBg;mkdl;G½kS .

- 33. viFIedaHRsaykñúgkarKNnaRbLayTwk RbLayragctuekaNBañy b-)atRbLay ( m) m-epIgeTvRbLay g tg m m tg cot 11 B-TTwgrgVHénépÞTwkxagelI( m ) ω-RkLaépÞénmuxkat; ( m² ) χ- brimaRténmuxkat;esImrbs;RbLay ( m ) R-kaMGIuRCUedWRk ( m0 ) C- emKuNénbrimaNFarTwk m 0,5 s Δ-kMBs;FaraTwksuvtþiPaB ( m ) n-PaBeRKImrbs;dIb¤TMrrbs;Twk - rUbmnþEdlRtUvedaHRsayman ÷ 2 ).1 mhbhhbmhW (m²) 2 1 22 1212).2 mhbmhb (m) W R ).3 (m) 2 2 12 mhb mhbh R R n C * 1 ).4 eday ny 5.1 ; mRm 11.0 ( Pavlosky ) ny 3.1 ; mRm 13.0 - 6 1 * 1 R n C ( Manning ) - RKC lg72.17 b¤ n K 72.17 1

- 34. - 72.17 1 n C lgR - gC 8 ( Darcy ) λ emKuN énDarcy . rYcvaTak;TgeTAnig Re ( cMnYnerNul ) . dv. Re Re manEckCa ÷ + Re cr = 2320 muxkat;ragmUl + Re cr = 580 muxkat;minmUl cMeBaHrbbTwk ÷ LamIENr Re < Re cr TYrb‘uyLg; Re > Re cr 5). B = b + 2mh (m) RbLayrg)ara:bUl tamsmIkar x2 = 2py ( P CatEmøénxñatRbEvg ) b¤ ( P Ca)ara:Em:Rt)a:ra:bUl) 2 1 m p h CMerArWLaTIv H = h + Δ ( m )

- 35. hphBhw .2 3 4 3 2 212ln212 P 212ln212 N PN PN Bh R 3 2 cMeBaH B ≥ h eKyk B RbLyrag ctþúekaNEkg bB hR B hB . viFIKNnael,ÓnTwkmFüm: Q vvQ . m/s iRcv . ( Chézy ) m/s l hegR v 8 KWekItecjBIrUbmnþ g v d l hl 2 2 gRIv 8 ; l he I gRIu el,ÓnDINamiuc viFIKNnabrimaNFarTwk Q m³ / s Q = v.w m³/s iRcwQ .. b¤ iRcwQ .. ( m³ / s ) Et Rcwk . dUecñH iKQ . ( m³ / s ) ikRicwwQ .. ( m³ / s ) edIm,IeGayrMhUrTwkkñúgRbLaymanlkçN³l¥KWeKRtUvBinitüeTAelIel,ÓnTwk v env = ≤ v mfüm ≤ v aff AQ0.2 ≤ w Q ≤ k.Q0.1 v env - el,ÓnkkPk; v aff - el,ÓneRcaHdac; cMeBaH K

- 36. xSac;mFüm k = 0.45 - 0.50 xSacFM 0.5 - 0.6 fμtUc 0.6 - 0.75 fμmFüm 0.75 – 0.90 fμ 1.30 – 1.60 dIl,ayxSac; 0.53 dIGIdæmFüm 0.62 dIGidæexSay 0.52 l,aydIGideRcIn 0.58 dIGidæ 0.75 - 0.85 cMeBaH A A = 0.33 ā W < 1.5 m / s A = 0.44 ā W = 1.5 eTA 3.5 m/s A = 0.55 ā W > 3.5 cMNaM - )atRbLaysMrab;eRsaceRsaB mantémøcab;BI b = 0.4 m eLIgeTA . vIFIbgðajGMBItémøΔ ( m ) Q m³ / s < 1.0 1-10 10-30 > 30 Δ m 0.25 0.40 0.50 0.60

- 39. Chapter 6 kareRbIR)as;taragBiesssMrab;KNna)a:ra:Em:Rt énRbLay tameKalkarN_énelak Agroskine GaceGaymanRKwHsMrab;KNna)a:ra:Em:RténRbLay edayeFIV karRsavRCaveTAelI)a:ra:Em:téntém R h-a ( kaMGIVRCUGIkEdlmanRbeyaCn¾) Rayon hydraulic a vantage . dUecñHCadMbUgRtUvCMnYy F CaGnuKmn¾ . sMrab;RbLayctuekaNBañy i Q m F . 4 1 0 sMrab;RbLayrag)a:ra:bUlIk i Q F 1524.0 enAkñúgtarag TI v énAnnexe KWmanbgðajGMBItémø hydraulique A vantage edaysÁal; F, n rbs; RbLay. KNnaplviC©aénkaredaHTwkecj tamrUbmnþEdl)ansikSarYc KW ÷ RicwQ .. Ricv . eKGaceFIVkarsikSaeTACeRmATwkEdlRtUvbMeBjKW Gnuvtþn¾ tamrUbmnþ d h a a-CeRmATwkEdlbMeBj h-CeRmATwkkñúglU d-Ggát;pi©tbMBg; eKdwgfa a=1.0 edaysmÁal;snÞsSn¾ 0 ¬sUnüÚ ¦ ]TahrN¾ ikQ 00 ; iRCv 000 ; 0000 . RCWK Canic©Cakal a < 1 . edaydwgfa edIm,IeFIVkarKNnaGMBIrUbmnþxagelIKWRtUv Kal;pleFob 0Q Q A nig 0v v B EdlTTYlxusRtUvcMeBaH brimaNFarTwk nig el,óÓnTwk .

- 40. tamrUb 8-8 )anbgðajfa A , B CaGnuKmn¾ En Q . kñúgkrN× MaxA naMeGay a = 0.95 MaxB naMeGay a = 0.81 CaTUeTAlkVN³rbs;K CaGnuKmn¾d , n , a . kñúgkarKNnan yktEmø0.013 ebId ≤ 600 mm . n yktEmø0.014 ebI d > 600 mm . cMeBaH Galerie , n RtUeRCIserIs tamtaragTI I kñúg Annexe . tEmøénko KWvapÞúyGMBIK dUecñHeKGacsresr iRBCv .00 iAKQ 0 RCWK 000 témønig B RtUveRCIserIstamExSekag rUb 8-8 edIm,IKNna k 0 , W 0 , C 0 , R o GacKNna . taragbgðajGMBI K 0 el,ÓnkMNt; v env = 0.7m/s cMeBaH d ≤ 500 mm venv = 0.5 m/s cMeBaH d > 500mm .

- 41. I.smIkar Continuité sMrab;clnaTwkGciéRnþ eKmanExSTwkmYyExSEdlman ÷ eK)an 332211 333 122 111 udwudwudw udwdQ udwdQ udwdQ ( équodion de continuité ) Q1 = Q2 = Q = Cont V1W1 = V2W2 = ……….. = V .W = const 1 2 2 1 w w v v II.smIkarEb‘rnuyy‘ÍsMrab;crnþTwk parfait ( Nonvisqueux ) 00 - bnÞat;eKal Z1 , Z2 - kMBs;eFomrvaggk½STwk nig 00 ΔS1 , ΔS2 - cMgaycr 1-1 , 1’-1’, 2-2 , 2’ – 2’ , muxkat;TwkRtg;cMNuc

- 42. ds1 = u1dt ds2 = u2dt Le travail des forces de pression : P1dw1u1dt – P2dw2u2dt = dQdt ( P1- P2 ) dQ = u1dw1 = u2dw2 dQ = u1dw1 = u2dw2 Le travail des forces de gravitaire = le travail par la force de gravité de la masse de liquide du tronçon 1-1’ EdlmankMritkMBs;xus ² Kña KW dG ( Z1 – Z2 ) = g ρdw ds1 ( Z1 - Z2 ) = gρdwu1dt (Z1 – Z2 ) = gρdQdt ( Z1 - Z2 ) tamkarpøas;TIBI 1-2 EdlmancrnþTwkGciE®nþ dUecñHkM/lMefrKW 2222 2 1 2 2 2 11 2 22 u dQdt u dQdt udmudm 2121 1 2 2 22 ZZdQdtgdQdt uu dQdt TIbBa©b;eKGacsresr)ansmIkar edayEckρdQdt RKb;GgÁTaMgBIr ÷ 22 2 22 2 2 11 1 uP gZ up gZ ( Bernoulli ) b£ g u g p Z g p Z 22 2 22 2 1 1 Z1 , Z2 famBlénkMBs; ( m ) g p g p 21 , famBlénsm<aF ( m ) g u g u 2 , 2 2 2 2 1 famBlsIueNTic ( m ) karviPaKeTAelIssmIkarBernoulli énrMhUrGciE®nþ g u g p Z g u g p Z 22 2 22 2 2 11 1 ( Bernoulli nonvisqueuse )

- 43. 1-ExS piézométrique 2-G½kSéncrnþTwk l g p Z g p Z I p 2 2 1 1 Ip = CMralGIuRdUlIk edIm,Icg;el,ÓnTwk eKRtUv]bkN¾ eQμaHtibBItU Pitot ghKu 2 III-smIkar Bernoulli sMrab;TwkFmμta ( Visqueux ) cph g u g P Z g u g p Z . 2 222 2 2 111 1 22 ( Bernoulli ) Z 1 , Z 2 - kMBs;eFüb ( m ) α1 , α 2 – emKuNkUr:UlIs α = 1.02 eTA1.03 g p g p 21 , - sMrab;famBlsm<aF ( m ) g u g u 2 , 2 21 - kMhat;bg;tambeNþay ; TTwg én bMBs; ( m )

![CMBUkTI1 Chapter 1

I-lkVN³TUeTAGeneral

I-1-1-niymn½yrbs;vtßúravDefinition of fluid

vtßúravmancrwkeRcInya:gKÅ :

k¦ CarUbFatuEdlfitenAeRkamTMrg;Caliquid nig Solid

x¦ vtßúrav KWCarUbFatuEdlmankarERbRbYlTMrg;kñúgkrNImanGMeBIBIxageRkA .

eKehAfa karcl½trbs;PaKl¥iténvtßúrav (Particulars of fluid) .

K¦kMLaMgxageRkAGacbNþalbegþIteGaymanCaclnarbs; fluid tamTisedAénkMLaMg .

X¦eKkMNt;tamlkVN³mCÄd§anénkarxUcRTg;RTay nig mCÄd§anénkareFVIbnþ.

g¦vtßúrav KWmanrUbragdUcmCÄd§anénkareFVIbnþ EdlbgðajGMBITMrg;m:UelKulrbs;rUbFatuedayKit

bBa¢ÚlTaMgemKuN nig smIkar constitutive .

c¦ eKEckCavtßúrav nig hÁas .

]TarhN_ ³ TwkCa fluid incompressible.

hÁasCa]s½μncompressible.

CaTUeTAeKkMNt;famanBIrsarxarbs;mecanic of fluid KW

a) DINamiuc én vtßúrav b¤ Hydrodynamic.

b) DINamiuc én haÁs b¤ Aerodynamic.

q¦ TMrgrbs;vtßúravKWmaneTAtamTMrrbs;eRKOgRTehIyépÞb:HCamYybriyakasvaCaépÞesrI (Face Free).

I-1-2-niymn½yrbs;GuIRdUDINamic Hydrodynamic

- sikSaeTAelIclnarbs; vtßúrav KWCamCÄd§anénkareFVIbnþ EdlTak;TgeTAnigrMhUrrbs; vtßúrav

nigRbsiTi§PaB epSg²eTotrbs;va .

- hÁasKWsikSaGMBIrMhUr]s½μnepSg ²

- emkanic énvtßúrav nig emkanic én vtßúrWg solidmansarsMxan;epSgKña² .](https://image.slidesharecdn.com/fluidkhmer-170622163357/85/-1-320.jpg)

![emkanic én vtßúravMechanic of Fliud

emkanic én vtßúrav (EdlmanCatiTwk, ]sμ½n) emkanic énvtßú rwg

GIuRdUDINamiuc GaeGrU:DINamiuc

Hydrodynamic Aerodynamic

I-1-3-RbePTénrMhUr Type flow

k¦ rMhUrrbs; vtßúrav Caclna Continue .

x¦ cMeBaH vtßú rWg bnøas;bþÚrCabøúk .

K¦ rMhUrrbs; vtßúrav manlkVN³Cael,Ón edaykMlaMgsm<aFniglkVN³epSgeTot dUcCadg;sIuet nig

Viscosity .

X¦ Viscosity KWCargVas;er:sIusþg; én vtßúrav rbs;rMhUrehIyKWCalkVN³kkitrvag clnaPaKl¥it .

c¦ Hydrodynamic KWCa Hydrostatic KWsikSavtßúravenAhñwgmYykEnøg.

q¦ rMhUr vtßúrav Bit KWCa Laminar ( rMhUrrbs;vamanlkVN³CaRsTab;²)

C¦ cMeBaHrMhUr Turbulent CarMhUrxñÚlxñaj;.

Q¦ rMhUurÉksNñan Uniform KW g = 0 ehIyviucT½r el,Ón Velocity RsbKñaRKb;cMNuc .

j¦ rMhUurCaTUeTAmanEbkCa x , y , z EdlmaneQñaHehAfa Tridimensionnel. RbsinebIrMhUrmanEt

BIrmuxRBYj KWCarMhUr Bidimensionnel b¤ Plan. EtebImanEtmYypøÚvrMhUrenHehAfa Unidimensionnel .

I-2- c,ab;rkSaTukénkMlaMg Laws of conservation

1-kMmøaMgmanEckCaBIrKW ³

– kMmøaMgekItedayTMnajEpndI Gravitational constant (g = 9.81m/s² )

–. kMmøaMgekItedaykarkkit nig sm<aF

2- kMmøaMgenHmanTMnak;TMngCamYy cMnYnerNul Reynolds (Re) KWmankMmøaMgniclPaB nigkMmøaMg sm<aF.

3-kñúgkarGnuvtþ eKman c,ab;rkSaTukénkMlaMgsMrab;sersrGMBIclna én vtßúrav.

i) c,ab;rkSaTukénm:as;tameKalkarRKwH én Continuity

ii ) c,ab;rkSaTukénbrimaNclnatameKalkarRKwH énm:Umg;( dynamic)](https://image.slidesharecdn.com/fluidkhmer-170622163357/85/-2-320.jpg)

![T = sItuNðPaBdac;xat

TR

p

g

dz

dp

.

'

cMeBaHvavtßúravIsotherme KWCakarERbRbYl

xdp

d

x - emKuN compressible isotherme x = 5 . 10-10

Pa ‘

bMErbMrYlénsm<aFsMrab; liquide compressible

rxpg

dz

d

10

Pr = sm<aFrWLaTIvedayeFobsm<aFerehVr:gPo . 0

6- vgVas;sm<aF Mesure de Pression

1-xñatsm<aF

2

m

N

S

F

P b£ F = kmøaMg

S = RkLaépÞrag

cMNaM ³ 1bar = 105

Pa = 106

bayers

Pa

m

kgf

81,9

1

2

mm

m

kgf

1

1

2

C.e

2-sm<aFbriyakas

eFobnIvUrbs;smuRT eKeXIjkMBs;)aet 760mm sm<aF P = 1.013 Pa xül; = 1.225 kg / m³ RtUvsItuNðPaB

T = 15 0

C b£ 288 0

k

3-]bkrN_vas;sm<aFbriyakas

3

42.133

m

kn

hg , sm<aFcMhay Pv = 0

Pression Z2 – Z1 = 760 mm C.e

attmosphérique](https://image.slidesharecdn.com/fluidkhmer-170622163357/85/-15-320.jpg)

![- Baromètre anéroide )ar:UEm:RtGaeNr:UGIut

- ]bkrN_vas;;sm<aFrWLaTIv( Pression relative )

111 hP sm<aFrWLaTIv

11

'

1 hPP a sm<aFdac;xat

- ma:NUEm:Rt( Manonètre)

eRbIkñúgbMBg;rag U Edlman 2 m ¬rbs;rlay ¦

2222 lhP m sm<aFrelative

222

'

2 lhPP ma

P2 nig P’

2 maneRbIedayvas;

h1 nigl2 emIltamRkit

m nig 2 CacMnYnmFüménHydromèter

Pa sm<aFbriyakas

34443 . lhlPP mm ](https://image.slidesharecdn.com/fluidkhmer-170622163357/85/-16-320.jpg)

![h

1h

0P

ghP 0

l4 , l 3 , Δh ( m )

43 ,, m Tm¶n;maDénvtßúrav

-ma:NUEm:Rtbr½dug

vide vism<aF

KWCaPaBxusKaμ énsm<aFvas;eXIj nig sm<aFbrikal ]-sm<aFvas;kñúgma:sIunbUmTwkman 0,690 bar

ehIysm<aFbriyakas xageRkAman 1,013bar dUecñH vide KW 1,013bar – 0,690 = 0.323 bar

cMNaM ³ P1 – P2 PaBxusKañésm<aF

A

F

P ,

g

hP

.

,

3

m

N

Pap

h

7- sm<aFénépÞesrI (Pression vide)

const

s

p

gz smIkarRKwH Hydrostatique

-sm<aFdac;xatPression absolue nigsm<aFdac;xatPression Manamètreque suBaØakasPression vide .

k¦smIkarRKwH

0

0

p

gz

s

p

gz

10 ghP ](https://image.slidesharecdn.com/fluidkhmer-170622163357/85/-17-320.jpg)

![Chapter 6

kareRbIR)as;taragBiesssMrab;KNna)a:ra:Em:Rt

énRbLay

tameKalkarN_énelak Agroskine GaceGaymanRKwHsMrab;KNna)a:ra:Em:RténRbLay edayeFIV

karRsavRCaveTAelI)a:ra:Em:téntém R h-a ( kaMGIVRCUGIkEdlmanRbeyaCn¾) Rayon hydraulic a vantage .

dUecñHCadMbUgRtUvCMnYy F CaGnuKmn¾ .

sMrab;RbLayctuekaNBañy

i

Q

m

F .

4

1

0

sMrab;RbLayrag)a:ra:bUlIk

i

Q

F 1524.0

enAkñúgtarag TI v énAnnexe KWmanbgðajGMBItémø hydraulique A vantage edaysÁal; F, n rbs;

RbLay. KNnaplviC©aénkaredaHTwkecj

tamrUbmnþEdl)ansikSarYc KW ÷

RicwQ ..

Ricv .

eKGaceFIVkarsikSaeTACeRmATwkEdlRtUvbMeBjKW Gnuvtþn¾

tamrUbmnþ

d

h

a a-CeRmATwkEdlbMeBj

h-CeRmATwkkñúglU

d-Ggát;pi©tbMBg;

eKdwgfa a=1.0 edaysmÁal;snÞsSn¾ 0 ¬sUnüÚ ¦

]TahrN¾ ikQ 00 ; iRCv 000 ; 0000 . RCWK

Canic©Cakal a < 1 . edaydwgfa edIm,IeFIVkarKNnaGMBIrUbmnþxagelIKWRtUv Kal;pleFob

0Q

Q

A nig

0v

v

B EdlTTYlxusRtUvcMeBaH brimaNFarTwk nig el,óÓnTwk .](https://image.slidesharecdn.com/fluidkhmer-170622163357/85/-39-320.jpg)

![1-ExS piézométrique

2-G½kSéncrnþTwk

l

g

p

Z

g

p

Z

I p

2

2

1

1

Ip = CMralGIuRdUlIk

edIm,Icg;el,ÓnTwk eKRtUv]bkN¾ eQμaHtibBItU Pitot

ghKu 2

III-smIkar Bernoulli sMrab;TwkFmμta ( Visqueux )

cph

g

u

g

P

Z

g

u

g

p

Z .

2

222

2

2

111

1

22

( Bernoulli )

Z 1 , Z 2 - kMBs;eFüb ( m )

α1 , α 2 – emKuNkUr:UlIs α = 1.02 eTA1.03

g

p

g

p

21

, - sMrab;famBlsm<aF ( m )

g

u

g

u

2

,

2

21

- kMhat;bg;tambeNþay ; TTwg én bMBs; ( m )](https://image.slidesharecdn.com/fluidkhmer-170622163357/85/-43-320.jpg)