Cambium network ptp 810 series 01 00 user guide

- 1. Cambium PTP 810 Series User Guide System Release 810-01-00

- 2. Accuracy While reasonable efforts have been made to assure the accuracy of this document, Cambium Networks assumes no liability resulting from any inaccuracies or omissions in this document, or from use of the information obtained herein. Cambium reserves the right to make changes to any products described herein to improve reliability, function, or design, and reserves the right to revise this document and to make changes from time to time in content hereof with no obligation to notify any person of revisions or changes. Cambium does not assume any liability arising out of the application or use of any product, software, or circuit described herein; neither does it convey license under its patent rights or the rights of others. It is possible that this publication may contain references to, or information about Cambium products (machines and programs), programming, or services that are not announced in your country. Such references or information must not be construed to mean that Cambium intends to announce such Cambium products, programming, or services in your country. Copyrights This document, Cambium products, and 3rd Party software products described in this document may include or describe copyrighted Cambium and other 3rd Party supplied computer programs stored in semiconductor memories or other media. Laws in the United States and other countries preserve for Cambium, its licensors, and other 3rd Party supplied software certain exclusive rights for copyrighted material, including the exclusive right to copy, reproduce in any form, distribute and make derivative works of the copyrighted material. Accordingly, any copyrighted material of Cambium, its licensors, or the 3rd Party software supplied material contained in the Cambium products described in this document may not be copied, reproduced, reverse engineered, distributed, merged or modified in any manner without the express written permission of Cambium. Furthermore, the purchase of Cambium products shall not be deemed to grant either directly or by implication, estoppel, or otherwise, any license under the copyrights, patents or patent applications of Cambium or other 3rd Party supplied software, except for the normal non-exclusive, royalty free license to use that arises by operation of law in the sale of a product. Restrictions Software and documentation are copyrighted materials. Making unauthorized copies is prohibited by law. No part of the software or documentation may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language or computer language, in any form or by any means, without prior written permission of Cambium. License Agreements The software described in this document is the property of Cambium and its licensors. It is furnished by express license agreement only and may be used only in accordance with the terms of such an agreement. High Risk Materials Components, units, or 3rd Party products used in the product described herein are NOT fault- tolerant and are NOT designed, manufactured, or intended for use as on-line control equipment in the following hazardous environments requiring fail-safe controls: the operation of Nuclear Facilities, Aircraft Navigation or Aircraft Communication Systems, Air Traffic Control, Life Support, or Weapons Systems (High Risk Activities). Cambium and its supplier(s) specifically disclaim any expressed or implied warranty of fitness for such High Risk Activities. © 2012 Cambium Networks Limited. All Rights Reserved. phn-2779_001v000 (Jul 2012)

- 3. PTP 810 Series User Guide Important safety information This section describes important safety guidelines that must be observed by personnel installing or operating PTP 810 equipment. To prevent loss of life or physical injury, observe the safety guidelines in this section. Power lines Exercise extreme care when working near power lines. Working at heights Exercise extreme care when working at heights. Grounding and protective earth The outdoor unit (ODU) and modular modem unit (MMU) for the PTP 810 must be properly grounded. It is the user’s responsibility to install the equipment in accordance with national regulations. In the USA, follow Section 810 of the National Electric Code, ANSI/NFPA No.70-1984 (USA). In Canada, follow Section 54 of the Canadian Electrical Code. These codes describe correct installation procedures for grounding the ODU, MMU, mast, lead-in wire and discharge unit, size of grounding conductors and connection requirements for grounding electrodes. Other regulations may apply in different countries and therefore it is recommended that installation of the outdoor unit be contracted to a professional installer. The ODU and MMU must be grounded to a protective earth in accordance with the Local Electrical Regulations. phn-2779_001v000 (Jul 2012) I

- 4. Important safety information Electrical safety The power cable connections must meet International Electrotechnical Commission (IEC) safety standards. Always power down and unplug the equipment before servicing. When using alternative DC supplies, such as battery-backed DC power source, the supply must be SELV rated. Primary disconnect device The power supply must include a primary disconnect device with appropriate fusing. External cables Safety may be compromised if outdoor rated cables are not used for connections that will be exposed to the weather. RF exposure near the antenna Strong radio frequency (RF) fields will be present close to the antenna when the transmitter is on. Always mute the transmitter before undertaking maintenance activities in front of the antenna. Ensure that people cannot stand or walk in front of the antenna within ± 10 degrees of the antenna axis and within the minimum distances listed in Table 220 (ETSI) or Table 221 (FCC). The minimum distances in these tables have been calculated using worst-case assumptions. Reduced separation distances may be appropriate under some circumstances. Further details are provided in Radiation hazard assessment on page 4-83. II phn-2779_001v000 (Jul 2012)

- 5. PTP 810 Series User Guide Contents Important safety information ........................................................................................... I About This User Guide ..................................................................................................... 1 General information ..................................................................................................................... 2 Version information................................................................................................................ 2 Contacting Cambium Networks ............................................................................................. 2 Problems and warranty ................................................................................................................ 4 Security advice ............................................................................................................................. 6 Warnings, cautions, and notes ..................................................................................................... 7 Caring for the environment.......................................................................................................... 8 Licensing requirements ............................................................................................................... 9 Operating license ................................................................................................................... 9 Cambium license agreement .................................................................................................. 9 Chapter 1: Product description .................................................................................. 1-1 Overview ................................................................................................................................... 1-2 Key features ........................................................................................................................ 1-2 Supported bands and frequencies ...................................................................................... 1-3 Typical users and applications ............................................................................................ 1-4 System components ............................................................................................................ 1-4 Link types ............................................................................................................................ 1-5 Dual 1+0 links ..................................................................................................................... 1-6 Wireless link aggregation ................................................................................................... 1-7 Modular modem unit (MMU) .................................................................................................... 1-8 MMU description ................................................................................................................ 1-8 Required modules ............................................................................................................... 1-8 Power Supply Module ......................................................................................................... 1-8 Control Module ................................................................................................................. 1-10 Modem Module ................................................................................................................. 1-11 Standard Master I/O module ............................................................................................. 1-12 GigE Master I/O module.................................................................................................... 1-13 Additional modules............................................................................................................ 1-14 Additional Power Supply Module ...................................................................................... 1-15 phn-2779_001v000 (Jul 2012) i

- 6. Contents Additional Modem Module ................................................................................................ 1-15 Expansion I/O: 16 × E1/T1 ................................................................................................ 1-16 Further reading on the MMU ........................................................................................... 1-17 Outdoor unit (ODU)................................................................................................................. 1-18 ODU description................................................................................................................ 1-18 ODU interfaces.................................................................................................................. 1-19 Further reading on the ODU ............................................................................................. 1-23 Antennas and couplers ............................................................................................................ 1-24 Antennas ........................................................................................................................... 1-24 Remote mounting kits (RMKs) .......................................................................................... 1-26 Coupler mounting kits....................................................................................................... 1-27 Direct mount dual-polar antennas .................................................................................... 1-29 Further reading on antennas and couplers....................................................................... 1-30 Cabling and lightning protection ............................................................................................ 1-31 Lightning protection ......................................................................................................... 1-31 ODU to MMU connections ................................................................................................ 1-31 MMU to network connections ........................................................................................... 1-31 Cable grounding................................................................................................................ 1-31 Further reading on cabling and lightning protection ....................................................... 1-33 Wireless operation .................................................................................................................. 1-34 Channel separation ........................................................................................................... 1-34 Channel bandwidth ........................................................................................................... 1-34 Modulation modes ............................................................................................................. 1-35 Adaptive power control ..................................................................................................... 1-35 Maximum receive power ................................................................................................... 1-36 Maximum transmit power ................................................................................................. 1-36 XPIC .................................................................................................................................. 1-36 Further reading on wireless operation ............................................................................. 1-37 Ethernet bridging in the customer network ........................................................................... 1-38 Transparent Ethernet service ........................................................................................... 1-38 Internal Ethernet switch ................................................................................................... 1-39 Spanning tree operation ................................................................................................... 1-40 Pause frame operation ...................................................................................................... 1-41 Ethernet link aggregation ................................................................................................. 1-41 Transparent wireless link aggregation (GigE Master I/O module) ................................... 1-42 VLAN bridging of Ethernet Traffic.................................................................................... 1-42 Quality of service for bridged Ethernet traffic ................................................................. 1-45 ii phn-2779_001v000 (Jul 2012)

- 7. PTP 810 Series User Guide Wireless link down alert.................................................................................................... 1-45 Further reading on Ethernet bridging .............................................................................. 1-46 Ethernet bridging in the management network...................................................................... 1-47 Embedded management agent.......................................................................................... 1-47 Serial interface .................................................................................................................. 1-47 Ethernet interface ............................................................................................................. 1-47 Network management ....................................................................................................... 1-48 Spanning tree operation ................................................................................................... 1-49 Network management quality of service .......................................................................... 1-49 System management ............................................................................................................... 1-50 Protocol interfaces ............................................................................................................ 1-50 Web server ........................................................................................................................ 1-50 Command line interface .................................................................................................... 1-50 Identity-based user accounts ............................................................................................ 1-51 Link configuration wizard ................................................................................................. 1-52 Alarms ............................................................................................................................... 1-52 SNMP ................................................................................................................................ 1-53 Simple Network Time Protocol (SNTP)............................................................................. 1-54 System logging (syslog) .................................................................................................... 1-54 Flexible capacity upgrades ............................................................................................... 1-54 Application software storage and upgrade ....................................................................... 1-55 Restore system defaults .................................................................................................... 1-56 Further reading on system management .......................................................................... 1-56 TDM bridging .......................................................................................................................... 1-57 E1/T1 capacity................................................................................................................... 1-57 E1/T1 clocking................................................................................................................... 1-58 Identification and mapping of E1/T1 circuits and ports ................................................... 1-59 E1/T1 switching in 1+0 and 1+1 link types ...................................................................... 1-59 Dual 1+0 links ................................................................................................................... 1-60 E1/T1 switching in 2+0 co-polar, 2+0 cross-polar and 2+0 XPIC link types ................... 1-61 Loopback ........................................................................................................................... 1-62 Further reading on TDM bridging .................................................................................... 1-62 Chapter 2: Planning considerations ........................................................................... 2-1 Link planning ............................................................................................................................ 2-2 Process ................................................................................................................................ 2-2 Site selection ....................................................................................................................... 2-3 Wind loading ....................................................................................................................... 2-3 phn-2779_001v000 (Jul 2012) iii

- 8. Contents Maximum IF cable length ................................................................................................... 2-3 PTP LINKPlanner ................................................................................................................ 2-4 Grounding and lightning protection ......................................................................................... 2-7 The need for power surge protection ................................................................................. 2-7 Standards ............................................................................................................................ 2-7 Lightning Protection Zones ................................................................................................. 2-8 General protection requirements........................................................................................ 2-9 Protection requirements for a mast or tower installation................................................. 2-10 Protection requirements for the ODU on a high rise building .......................................... 2-12 Data network planning............................................................................................................ 2-16 IP interface........................................................................................................................ 2-16 Quality of service for bridged Ethernet traffic ................................................................. 2-16 Fast Ethernet port shutdown ............................................................................................ 2-18 TDM network planning ........................................................................................................... 2-19 E1/T1 termination points and pass-through ..................................................................... 2-19 Protection requirements ................................................................................................... 2-19 2+0 link failover preference ............................................................................................. 2-20 TDM and Ethernet traffic capacity tradeoffs .................................................................... 2-20 Planning 1+0 links .................................................................................................................. 2-22 Concept of a 1+0 link........................................................................................................ 2-22 Antenna, ODU and MMU configurations for 1+0 ............................................................. 2-22 Planning 1+1 links .................................................................................................................. 2-25 Concept of a 1+1 Hot Standby link .................................................................................. 2-25 Concept of a 1+1 Hot Standby Spatial Diversity link ....................................................... 2-25 Antenna, ODU and MMU configurations for 1+1 links .................................................... 2-26 Designating primary and secondary units ........................................................................ 2-30 Link planning for 1+1 Hot Standby links ......................................................................... 2-30 Link planning for Spatial Diversity ................................................................................... 2-30 Planning 2+0 links .................................................................................................................. 2-31 Concept of a 2+0 link........................................................................................................ 2-31 Antenna, ODU and MMU configurations for 2+0 ............................................................. 2-31 Frequency spacing ............................................................................................................ 2-36 Planning Dual 1+0 links.......................................................................................................... 2-37 BOM for ring and ribbon topologies ................................................................................. 2-37 1+0 Ribbon topology......................................................................................................... 2-37 1+0 Ring topology ............................................................................................................ 2-38 Ordering components ............................................................................................................. 2-39 iv phn-2779_001v000 (Jul 2012)

- 9. PTP 810 Series User Guide Ordering MMUs ................................................................................................................ 2-39 Ordering capacity upgrades and XPIC capability ............................................................. 2-40 Ordering antennas ............................................................................................................ 2-44 Ordering ODUs ................................................................................................................. 2-54 Ordering IF cable, grounding and LPUs ........................................................................... 2-65 Ordering RMKs and waveguides ....................................................................................... 2-70 Ordering coupler mounting kits ........................................................................................ 2-73 Ordering OMKs ................................................................................................................. 2-75 Ordering network connection components ....................................................................... 2-75 Chapter 3: Legal information ..................................................................................... 3-1 Cambium Networks end user license agreement ..................................................................... 3-2 Acceptance of this agreement ............................................................................................. 3-2 Definitions ........................................................................................................................... 3-2 Grant of license ................................................................................................................... 3-2 Conditions of use ................................................................................................................. 3-3 Title and restrictions ........................................................................................................... 3-4 Confidentiality ..................................................................................................................... 3-4 Right to use Cambium’s name ............................................................................................ 3-5 Transfer ............................................................................................................................... 3-5 Updates ............................................................................................................................... 3-5 Maintenance........................................................................................................................ 3-5 Disclaimer ........................................................................................................................... 3-6 Limitation of liability ........................................................................................................... 3-6 U.S. government ................................................................................................................. 3-7 Term of license .................................................................................................................... 3-7 Governing law ..................................................................................................................... 3-7 Assignment .......................................................................................................................... 3-8 Survival of provisions .......................................................................................................... 3-8 Entire agreement ................................................................................................................ 3-8 Third party software ........................................................................................................... 3-8 Limit of liability ......................................................................................................................... 3-9 Chapter 4: Reference information .............................................................................. 4-1 Equipment specifications .......................................................................................................... 4-2 MMU specifications ............................................................................................................ 4-2 ODU specifications .............................................................................................................. 4-5 Flexible waveguide specifications ....................................................................................... 4-9 Coupler mounting kit specifications ................................................................................. 4-14 phn-2779_001v000 (Jul 2012) v

- 10. Contents MMU front panel connectors ............................................................................................ 4-16 Wireless specifications ............................................................................................................ 4-23 General wireless specifications......................................................................................... 4-23 Frequency bands and channel separation ........................................................................ 4-24 Capacity license keys and frequency bands...................................................................... 4-25 Maximum E1/T1 circuit capacity ...................................................................................... 4-27 Capacity, transmit power and sensitivity .......................................................................... 4-29 Data network specifications .................................................................................................... 4-73 Fast Ethernet specifications ............................................................................................. 4-73 Gigabit Ethernet specifications ......................................................................................... 4-75 Network management specifications ...................................................................................... 4-77 Standard SNMP MIBs ....................................................................................................... 4-77 Electromagnetic compliance ................................................................................................... 4-79 Compliance testing ........................................................................................................... 4-79 Electrical safety compliance ............................................................................................. 4-79 European Union compliance ............................................................................................. 4-80 Canada compliance ........................................................................................................... 4-80 United States compliance ................................................................................................. 4-81 Notifications ...................................................................................................................... 4-82 Radiation hazard assessment .................................................................................................. 4-83 ETSI method ..................................................................................................................... 4-83 FCC method ...................................................................................................................... 4-85 Chapter 5: Installation .............................................................................................. 5-1 Preparing for installation .......................................................................................................... 5-2 Safety precautions during installation ................................................................................ 5-2 Grounding and lightning protection requirements ............................................................. 5-2 Selecting installation options .............................................................................................. 5-2 Preparing personnel............................................................................................................ 5-3 Preparing inventory ............................................................................................................ 5-3 Preparing tools .................................................................................................................... 5-3 Installing antennas and ODUs .................................................................................................. 5-5 Installing a direct mount antenna with one ODU ............................................................... 5-6 Installing a remote mount antenna with one ODU ........................................................... 5-10 Installing a direct mount antenna with two ODUs (via coupler) ...................................... 5-21 Installing a remote mount antenna with two ODUs (via coupler) .................................... 5-28 Installing a direct mount dual-polar antenna with two ODUs .......................................... 5-34 Installing the IF and ground cables ........................................................................................ 5-38 vi phn-2779_001v000 (Jul 2012)

- 11. PTP 810 Series User Guide Preparing IF cables ........................................................................................................... 5-40 Fitting an N type or straight TNC connector .................................................................... 5-40 Fitting a right angle TNC connector ................................................................................. 5-44 Connecting the ODU to the top LPU ................................................................................. 5-44 Weatherproofing an N type connector .............................................................................. 5-47 Hoisting the main IF cable ................................................................................................ 5-52 Installing and grounding the main IF cable ...................................................................... 5-55 Making an IF cable ground point ...................................................................................... 5-57 Installing and grounding the IF cable at building entry ................................................... 5-61 Testing the ODU and IF cable ................................................................................................. 5-63 Recommended pre-power tests ......................................................................................... 5-63 Test equipment ................................................................................................................. 5-63 Test preparation ................................................................................................................ 5-64 Testing cable loss .............................................................................................................. 5-65 Measuring distance to fault .............................................................................................. 5-68 Installing the MMU ................................................................................................................. 5-71 Mounting the MMU ........................................................................................................... 5-71 Grounding the MMU ......................................................................................................... 5-72 Connecting the MMU to the IF cable................................................................................ 5-73 Connecting the MMU power supply ................................................................................. 5-73 Preparing network connections (1+0 and 2+0 links) ............................................................. 5-77 Installing an Ethernet data interface ................................................................................ 5-78 Installing a fiber data interface......................................................................................... 5-79 Installing a management interface ................................................................................... 5-82 Installing an E1/T1 interface ............................................................................................. 5-83 Installing an XPIC interface .............................................................................................. 5-85 Chapter 6: Configuration and alignment .................................................................... 6-1 Preparing for configuration and alignment .............................................................................. 6-2 Safety precautions during configuration and alignment .................................................... 6-2 Regulatory compliance during configuration and alignment .............................................. 6-2 Selecting configuration options .......................................................................................... 6-2 Purchasing license key ........................................................................................................ 6-2 Task 1: Connecting to the unit .................................................................................................. 6-3 Configuring the management PC ........................................................................................ 6-3 Updating the ARP table....................................................................................................... 6-6 Connecting to the PC and powering up .............................................................................. 6-7 Logging into the web interface ........................................................................................... 6-7 phn-2779_001v000 (Jul 2012) vii

- 12. Contents Logging into the CLI interface ............................................................................................ 6-9 Task 2: Configuring IP and Ethernet interfaces ..................................................................... 6-14 Configuring the IP interface ............................................................................................. 6-14 Reconnecting to the management PC ............................................................................... 6-15 Configuring Serial Port ..................................................................................................... 6-15 Configuring Ethernet payload ........................................................................................... 6-16 Configuring Ethernet network management .................................................................... 6-21 Task 3: Configuring wireless interface ................................................................................... 6-24 Viewing the configuration summary ................................................................................. 6-24 Updating link configuration .............................................................................................. 6-25 Configuring the ODU ........................................................................................................ 6-33 Configuring APC and coupler loss compensation ............................................................. 6-34 Task 4: Configuring E1/T1 interfaces ..................................................................................... 6-38 Configuring channel mapping ........................................................................................... 6-38 Configuring E1/T1 ports ................................................................................................... 6-42 Configuring E1/T1 protection switching ........................................................................... 6-45 Task 5: Configuring data orderwire ........................................................................................ 6-48 Configuring orderwire ...................................................................................................... 6-48 Task 6: Configuring protection ............................................................................................... 6-50 Configuring protection ...................................................................................................... 6-50 Task 7: Setting up SNMP agent .............................................................................................. 6-54 Configuring SNMP agent .................................................................................................. 6-54 Task 8: Configuring alarms and messages ............................................................................. 6-57 Configuring generation of diagnostics alarms .................................................................. 6-57 Configuring alarm thresholds ........................................................................................... 6-59 Task 9: Configuring syslog ...................................................................................................... 6-62 Configuring system logging (syslog) ................................................................................. 6-62 Task 10: Configuring quality of service .................................................................................. 6-63 Setting QoS priority method ............................................................................................. 6-63 Setting QoS port priorities ................................................................................................ 6-66 Setting QoS VLAN p-bit tag priorities .............................................................................. 6-68 Setting QoS DiffServ DSCP priorities ............................................................................... 6-69 Setting QoS switch priorities ............................................................................................ 6-71 Task 11: Configuring VLAN .................................................................................................... 6-73 Configuring global VLAN options ..................................................................................... 6-73 Configuring static VLANs ................................................................................................. 6-75 Configuring port based VLANs ......................................................................................... 6-77 viii phn-2779_001v000 (Jul 2012)

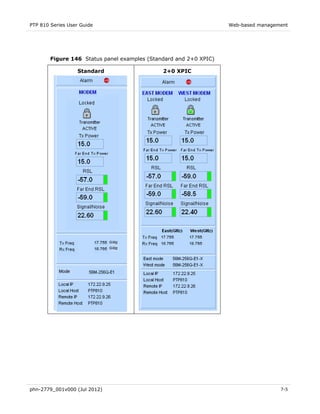

- 13. PTP 810 Series User Guide Example VLAN configurations .......................................................................................... 6-78 Configuring MSTPs ........................................................................................................... 6-88 Mapping VLANs to MSTP instances ................................................................................. 6-91 Task 12: LACP configuration .................................................................................................. 6-92 Configuring LACP ............................................................................................................. 6-92 Task 13: Connecting link to the network ................................................................................ 6-94 Connecting to the network................................................................................................ 6-94 Setting the real-time clock ................................................................................................ 6-95 Task 14: Aligning antennas ..................................................................................................... 6-98 Introduction to antenna alignment ................................................................................... 6-98 Prerequisites for alignment .............................................................................................. 6-99 Aligning protected antennas ............................................................................................. 6-99 Aligning dual-polar antennas ............................................................................................ 6-99 Aligning a pair of antennas ............................................................................................. 6-100 Starting antenna alignment ............................................................................................ 6-100 Aligning antennas ........................................................................................................... 6-100 Completing alignment ..................................................................................................... 6-103 Task 15: Reviewing configuration and performance ............................................................ 6-104 Reviewing system configuration attributes..................................................................... 6-104 Monitoring link performance .......................................................................................... 6-105 Chapter 7: Operation ................................................................................................. 7-1 Web-based management ........................................................................................................... 7-2 Accessing the web interface ............................................................................................... 7-2 Layout of the web interface ................................................................................................ 7-3 Viewing the system status................................................................................................... 7-4 Using the menu options ...................................................................................................... 7-9 Logging out ....................................................................................................................... 7-14 Managing alarms and events .................................................................................................. 7-15 Managing alarms .............................................................................................................. 7-15 Managing SNMP traps ...................................................................................................... 7-20 Managing event notification messages ............................................................................. 7-20 Disabling, enabling, muting and unmuting the ODU .............................................................. 7-21 Disabling the ODU ............................................................................................................ 7-21 Enabling the ODU ............................................................................................................. 7-22 Muting the ODU ................................................................................................................ 7-22 Unmuting the ODU ........................................................................................................... 7-22 Managing 1+1 Hot Standby links ........................................................................................... 7-23 phn-2779_001v000 (Jul 2012) ix

- 14. Contents Forcing protection switches.............................................................................................. 7-23 Enabling revertive and non-revertive switching ............................................................... 7-23 Enabling and disabling fault protection ............................................................................ 7-24 Selecting preferred transmitting ODU ............................................................................. 7-24 Managing 2+0 Co-Polar, Cross-Polar & XPIC links ................................................................ 7-25 GigE Master I/O operation ................................................................................................ 7-25 Standard Master I/O operation ......................................................................................... 7-26 Link outage considerations ............................................................................................... 7-26 Managing user accounts and security .................................................................................... 7-27 Creating user accounts ..................................................................................................... 7-27 Deleting user accounts ..................................................................................................... 7-28 Changing a password ........................................................................................................ 7-29 Viewing event log of MMU access .................................................................................... 7-29 Configuring HTTP (SSL) ................................................................................................... 7-30 Managing performance ........................................................................................................... 7-31 Viewing wireless link performance ................................................................................... 7-31 Viewing Ethernet switch statistics .................................................................................... 7-42 Maintaining the system ..................................................................................................... 7-50 Saving, restoring and rebooting ............................................................................................. 7-51 Saving the system configuration ....................................................................................... 7-51 Restoring the system configuration .................................................................................. 7-52 Rebooting .......................................................................................................................... 7-53 Checking the recovery version ......................................................................................... 7-53 Restoring system defaults ....................................................................................................... 7-54 Power on reset to system defaults .................................................................................... 7-54 Restore system defaults page ........................................................................................... 7-54 System default parameter values ..................................................................................... 7-55 Viewing device information .................................................................................................... 7-57 General device information ............................................................................................... 7-57 Serial number information ................................................................................................ 7-58 Device name and owner information ................................................................................ 7-58 Upgrading the system ............................................................................................................. 7-60 Entering an authorization key........................................................................................... 7-60 Installing new software versions ...................................................................................... 7-63 Removing and installing modules ........................................................................................... 7-67 Preparing to remove and install a module ........................................................................ 7-67 Removing a module ........................................................................................................... 7-68 x phn-2779_001v000 (Jul 2012)

- 15. PTP 810 Series User Guide Installing a module ............................................................................................................ 7-69 Installing dual modem upgrade kit ................................................................................... 7-69 Software images stored on MMU modules ....................................................................... 7-70 Chapter 8: Troubleshooting ....................................................................................... 8-1 Trouble connecting to the web management interface ............................................................ 8-2 Check the MMU power supply status LED ......................................................................... 8-2 Check the DC supply to the MMU ...................................................................................... 8-2 Check the MMU status indicators....................................................................................... 8-3 Check the NMS port Ethernet connection .......................................................................... 8-3 Check IP network connection ............................................................................................. 8-4 Check browser settings ....................................................................................................... 8-5 Using a serial port connection to set the IP address .......................................................... 8-5 Unable to access MMU using HTTPS ................................................................................. 8-6 Unable to access MMU using Telnet .................................................................................. 8-7 Unable to access MMU using SSH ..................................................................................... 8-7 Unable to access MMU using serial port ............................................................................ 8-7 Trouble establishing a wireless link .......................................................................................... 8-8 Connect to the web management interface ........................................................................ 8-8 Check for proper link configuration and connectivity ........................................................ 8-8 Transmitter status ............................................................................................................. 8-10 Antenna alignment ............................................................................................................ 8-10 Check transmit and receive frequencies ........................................................................... 8-11 Check waveguide and antennas ........................................................................................ 8-11 Check link status ............................................................................................................... 8-11 Trouble bridging Ethernet data traffic ................................................................................... 8-12 Trouble bridging E1/T1 traffic ................................................................................................ 8-15 Check for proper configuration and connectivity ............................................................. 8-15 Performing a loopback test ............................................................................................... 8-15 BERT mode........................................................................................................................ 8-18 Trouble managing remote unit ............................................................................................... 8-20 Glossary ........................................................................................................................... I Alarms ............................................................................................................................. V phn-2779_001v000 (Jul 2012) xi

- 16. PTP 810 Series User Guide List of Figures Figure 1 Typical PTP 810 deployment .......................................................................................... 1-4 Figure 2 Example of a 1+0 ring configuration .............................................................................. 1-7 Figure 3 MMU module locations ................................................................................................... 1-8 Figure 4 MMU module Power Supply Module front panel ........................................................... 1-9 Figure 5 MMU Control Module front panel ................................................................................ 1-10 Figure 6 MMU Modem Module front panel ................................................................................ 1-11 Figure 7 MMU Standard Master I/O Module front panel ........................................................... 1-13 Figure 8 MMU GigE Master I/O Module front panel .................................................................. 1-14 Figure 9 MMU additional module locations ................................................................................ 1-15 Figure 10 MMU XPIC cable linking two Modem Modules ......................................................... 1-16 Figure 11 MMU expansion I/O: 16 × E1/T1 front panel ............................................................. 1-16 Figure 12 ODU-A front view ........................................................................................................ 1-20 Figure 13 ODU-B front view ........................................................................................................ 1-20 Figure 14 ODU rear view ............................................................................................................ 1-21 Figure 15 ODU-A side view ......................................................................................................... 1-21 Figure 16 ODU-B side view ......................................................................................................... 1-22 Figure 17 Typical PTP 810 antenna with ODU (Cambium direct mount interface) .................... 1-24 Figure 18 Direct mount mechanical interface ............................................................................ 1-25 Figure 19 ODU clipped onto direct mount mechanical interface ............................................... 1-25 Figure 20 Remote mount antenna waveguide interface ............................................................. 1-25 Figure 21 RMK showing the ODU interface................................................................................ 1-26 Figure 22 RMK showing the waveguide interface ...................................................................... 1-27 Figure 23 ODU coupler mounting kit .......................................................................................... 1-28 Figure 24 Two ODUs and antenna mounted on a coupler .......................................................... 1-28 Figure 25 Orthogonal mode transducer ...................................................................................... 1-29 Figure 26 Cable grounding kit (Cambium part number 01010419001) ..................................... 1-32 Figure 27 LPU end kit (Cambium part number WB3657) ........................................................... 1-32 Figure 28 Internal Ethernet switch for the Standard Master I/O module .................................. 1-39 Figure 29 Internal Ethernet switch for the GigE Master I/O module ......................................... 1-40 Figure 30 Internal Ethernet switch for the management network ............................................. 1-48 Figure 31 Switching of E1/T1 circuits in 1+0 and 1+1 links ...................................................... 1-59 phn-2779_001v000 (Jul 2012) xii

- 17. PTP 810 Series User Guide Figure 32 Supported loopback tests ........................................................................................... 1-62 Figure 33 LINKPlanner profile view ............................................................................................. 2-5 Figure 34 LINKPlanner configuration and performance details ................................................... 2-6 Figure 35 LINKPlanner Bill of Materials view .............................................................................. 2-6 Figure 36 Rolling sphere method to determine the lightning protection zones ........................... 2-8 Figure 37 Grounding and lightning protection on mast or tower ............................................... 2-11 Figure 38 Grounding and lightning protection on mast or tower (protected end) ..................... 2-12 Figure 39 Grounding and lightning protection on building ........................................................ 2-13 Figure 40 Grounding and lightning protection inside high building ........................................... 2-14 Figure 41 Grounding and lightning protection inside high building (protected end) ................. 2-15 Figure 42 PTP 810 MMU Ethernet QoS Priority Queue.............................................................. 2-17 Figure 43 Schematic view of 1+0 ODU direct mount link end ................................................... 2-23 Figure 44 Schematic view of 1+0 ODU remote mount link end ................................................. 2-24 Figure 45 ODUs coupled to single direct mount antenna (schematic) ....................................... 2-26 Figure 46 ODUs coupled to single remote mount antenna (schematic) ..................................... 2-27 Figure 47 ODUs with separate direct mount antennas (schematic) ........................................... 2-28 Figure 48 ODUs with separate remote mount antennas (schematic) ......................................... 2-29 Figure 49 ODUs coupled to single direct mount antenna - co-polar links (schematic) ............... 2-32 Figure 50 ODUs coupled to a single remote mount antenna - co-polar links (schematic) .......... 2-33 Figure 51 ODUs coupled to a single direct mount antenna - cross-polar links (schematic) ....... 2-34 Figure 52 ODUs connected to a dual polar remote mount antenna - cross-polar links (schematic) ................................................................................................................................................ 2-35 Figure 53 Location of chassis serial number on MMU enclosure ............................................... 2-42 Figure 54 Locations of waveguide flanges .................................................................................... 4-9 Figure 55 Waveguide flanges – 6 GHz ........................................................................................ 4-11 Figure 56 Waveguide flanges – 7 to 15 GHz ............................................................................... 4-12 Figure 57 Waveguide flanges – 18 to 38 GHz ............................................................................. 4-13 Figure 58 Waveguide flanges – 11 GHz tapered transition......................................................... 4-13 Figure 59 Molex LFH Matrix 50 Receptacle 100 Ω /120 Ω Balanced interface .......................... 4-19 Figure 60 Data order wire - RS-422 connector ............................................................................ 4-21 Figure 61 Data order wire - RS-232 connector ............................................................................ 4-21 Figure 62 XPIC connector (Modem module) ............................................................................... 4-21 Figure 63 ODU connector (Modem module) ............................................................................... 4-22 Figure 64 European Union compliance label .............................................................................. 4-82 Figure 65 Dual-polar antenna in remote mount configuration ................................................... 5-11 Figure 66 Words embossed on coupler ....................................................................................... 5-22 Figure 67 Correct orientation of LPUs ........................................................................................ 5-39 phn-2779_001v000 (Jul 2012) xiii

- 18. List of Figures Figure 68 ODU and top LPU grounding ...................................................................................... 5-44 Figure 69 Using the hoist line ..................................................................................................... 5-54 Figure 70 IF cable grounding on a mast or tower ...................................................................... 5-55 Figure 71 Grounding at building entry ....................................................................................... 5-61 Figure 72 Example of a cable analyzer ....................................................................................... 5-64 Figure 73 Example of the cable test ........................................................................................... 5-64 Figure 74 Cable loss plot for a 14 meter cable with no ODU ..................................................... 5-66 Figure 75 Cable loss plot for a 14 meter cable with ODU connected ......................................... 5-67 Figure 76 DTF plot for a 17 meter cable with no ODU ............................................................... 5-69 Figure 77 DTF plot for a 17 meter cable with ODU connected .................................................. 5-70 Figure 78 MMU with rack mounting bracket (front mounting option shown)............................ 5-71 Figure 79 MMU ground connector ............................................................................................. 5-72 Figure 80 MMU IF cable connector (non-standard connector shown) ....................................... 5-73 Figure 81 MMU DC power cable connector ............................................................................... 5-74 Figure 82 MMU with power cable connected ............................................................................. 5-75 Figure 83 Copper data interface connections ............................................................................. 5-78 Figure 84 Fiber data interface connections ................................................................................ 5-79 Figure 85 Management interface connections............................................................................ 5-82 Figure 86 E1/T1 interface (RJ-48C) ............................................................................................. 5-83 Figure 87 E1/T1 interface (molex 60-pin) ................................................................................... 5-84 Figure 88 XPIC interface ............................................................................................................. 5-85 Figure 89 Starting Information page ............................................................................................ 6-8 Figure 90 CLI General Information page .................................................................................... 6-10 Figure 91 CLI Main Menu page .................................................................................................. 6-11 Figure 92 Example of a configurable CLI page........................................................................... 6-12 Figure 93 General Network Configuration page......................................................................... 6-14 Figure 94 Serial Configuration page ........................................................................................... 6-16 Figure 95 Ethernet Payload page for MMU Standard Master I/O module ................................. 6-17 Figure 96 Ethernet Payload page for MMU GigE Master I/O module ........................................ 6-18 Figure 97 Ethernet Payload page for MMU GigE Master I/O module with an SFP module ....... 6-19 Figure 98 Ethernet NMS page .................................................................................................... 6-22 Figure 99 Summary of Configurations page ............................................................................... 6-24 Figure 100 ODU Operational Mode page.................................................................................... 6-26 Figure 101 IDU Operational mode page ..................................................................................... 6-27 Figure 102 Payload Configuration page...................................................................................... 6-28 Figure 103 ODU Tx Power Configuration page .......................................................................... 6-29 Figure 104 ODU Channel Selection page ................................................................................... 6-31 xiv phn-2779_001v000 (Jul 2012)

- 19. PTP 810 Series User Guide Figure 105 Adaptive Coding Modulation page ............................................................................ 6-31 Figure 106 Summary of Configurations page with Redo and Update All buttons ...................... 6-33 Figure 107 ODU Tx Mute page ................................................................................................... 6-34 Figure 108 APC Configuration page ........................................................................................... 6-35 Figure 109 E1/T1 Channel Map page (pre-defined mapping) ..................................................... 6-39 Figure 110 E1/T1 Channel Map page (custom mapping) ............................................................ 6-41 Figure 111 E1/T1 Channel Map page (custom mapping updated).............................................. 6-41 Figure 112 E1/T1 Configurations page ....................................................................................... 6-43 Figure 113 E1/T1 Protection Switching page ............................................................................. 6-45 Figure 114 Voice Orderwire Configuration ................................................................................. 6-49 Figure 115 Protection Configuration page .................................................................................. 6-50 Figure 116 Remote transmit switch algorithm ........................................................................... 6-53 Figure 117 SNMP Configuration page ........................................................................................ 6-54 Figure 118 Alarm Configuration page......................................................................................... 6-58 Figure 119 Alarm Threshold page ............................................................................................... 6-60 Figure 120 Syslog Configuration page ........................................................................................ 6-62 Figure 121 QoS Global Configuration page (Standard Master I/O module) ............................... 6-63 Figure 122 QoS Global Configuration page (GigE Master I/O module) ...................................... 6-65 Figure 123 QoS Port Priority Map page (Standard Master I/O module)..................................... 6-67 Figure 124 QoS Port Priority Map for GigE Master I/O module ................................................. 6-68 Figure 125 QoS VLAN p-bit Tag Priority Map page .................................................................... 6-69 Figure 126 QoS DiffServ DSCP Map page (Standard Master I/O module) ................................. 6-70 Figure 127 QoS DiffServ DSCP Priority Map for GigE Master I/O module................................. 6-71 Figure 128 Switch Priority to Tx Priority Queue Map (GigE Master I/O module) ...................... 6-72 Figure 129 Global VLAN Configuration page.............................................................................. 6-74 Figure 130 Static VLAN Configuration ....................................................................................... 6-76 Figure 131 Add/Edit VLAN Configuration ................................................................................... 6-76 Figure 132 Port Based Forwarding Mode page .......................................................................... 6-77 Figure 133 MSTP Configuration page (when no MSTP instances exist)..................................... 6-89 Figure 134 MSTP Configuration page (when MSTP instances exist) ........................................ 6-89 Figure 135 MSTP Instance to VLAN Map page .......................................................................... 6-91 Figure 136 LACP Configuration page ......................................................................................... 6-92 Figure 137 LACP Status page ..................................................................................................... 6-93 Figure 138 Set Data & Time page (SNTP disabled) .................................................................... 6-96 Figure 139 Set Data & Time page (SNTP enabled)..................................................................... 6-97 Figure 140 Symmetrical relationship between voltage and alignment ..................................... 6-102 Figure 141 Typical RSSI voltage peaks and troughs ................................................................ 6-102 phn-2779_001v000 (Jul 2012) xv

- 20. List of Figures Figure 142 Summary of Configuration page ............................................................................. 6-104 Figure 143 System Administration Login page ............................................................................. 7-2 Figure 144 Web interface without status panel ............................................................................ 7-3 Figure 145 Web interface with status panel ................................................................................. 7-4 Figure 146 Status panel examples (Standard and 2+0 XPIC) ...................................................... 7-5 Figure 147 Status panel examples (Protected Non-diversity, East/East and East/West) ............. 7-6 Figure 148 Menu bar .................................................................................................................... 7-9 Figure 149 Active Alarms page ................................................................................................... 7-15 Figure 150 Alarm History page ................................................................................................... 7-18 Figure 151 ODU Configuration page .......................................................................................... 7-21 Figure 152 Add User page .......................................................................................................... 7-27 Figure 153 Delete User page ...................................................................................................... 7-28 Figure 154 Event Log page ......................................................................................................... 7-29 Figure 155 Security Configuration page ..................................................................................... 7-30 Figure 156 RSL Graph ................................................................................................................ 7-32 Figure 157 Signal Noise Ratio Graph ......................................................................................... 7-33 Figure 158 XPIC SNR Graph ....................................................................................................... 7-34 Figure 159 Tx Power Graph ........................................................................................................ 7-35 Figure 160 RF Link Performance Graph ..................................................................................... 7-36 Figure 161 Equalizer Taps Graph ............................................................................................... 7-37 Figure 162 XPIC Equalizer Taps Graph ...................................................................................... 7-38 Figure 163 Constellation Graph (256 QAM) ............................................................................... 7-39 Figure 164 XPIC Constellation Graph (256 QAM) ...................................................................... 7-40 Figure 165 Temperature Graph .................................................................................................. 7-41 Figure 166 NMS Switch Statistics page ..................................................................................... 7-42 Figure 167 Data Switch (payload port) Statistics page .............................................................. 7-44 Figure 168 Ethernet NMS – IEEE 802.1w RSTP Status page ..................................................... 7-46 Figure 169 Ethernet Payload – IEEE 802.1w RSTP page ........................................................... 7-47 Figure 170 Ethernet Payload – IEEE 802.1s MSTP page ............................................................ 7-48 Figure 171 Save/Restore Configuration page ............................................................................. 7-51 Figure 172 System Reboot page ................................................................................................. 7-53 Figure 173 Restore System Defaults page .................................................................................. 7-55 Figure 174 Device Information page........................................................................................... 7-57 Figure 175 Serial Number Information page .............................................................................. 7-58 Figure 176 Device Names page .................................................................................................. 7-59 Figure 177 Authorization Key ..................................................................................................... 7-61 Figure 178 XPIC Authorization Key ............................................................................................ 7-62 xvi phn-2779_001v000 (Jul 2012)