半導體廠耗能指標及節能方案之研究

- 1. 半導體廠耗能指標及節能方案之研究 指導教授 : 胡石政 博士

- 2. 希望建立半導體廠耗能指標 , 與各相關半導體廠做相對應比較 建立更良好的能源使用模式,在能源使用上更有效率 簡介 台灣高科技產業,以半導體晶圓製造及光電產業為主,高科技 產業之能源需求量相當龐大。

- 3. 潔淨室最佳化設計包含系統節能的設計 潔淨室最佳化設計包含系統節能的設計,一個節能化的潔淨室設計雖然有些會增加初設成本的支出,但總體而言,經過了二、三年運轉後其減少的電費,往往可大於當初初設成本的費用;其潔淨室的節約能源技術主要項目約分為十八類: ( 一 ) 、冰水主機系統 ( 二 ) 、 冰水系統 ( 三 ) 、冷卻水系統 ( 四 ) 、 外氣空調箱 ( 五 ) 、 排氣系統 ( 六 ) 、照明系統 ( 七 ) 、電力系統 ( 八 ) 、儲冰系統 ( 九 ) 、吸收式冰水主機 ( 十 ) 、 C / R 內循環送風系統 ( 十一 ) 、微環境系統 ( 十二 ) 、終級過濾器最省能配置 ( 十三 ) 、 MAU 出風口位置選擇 ( 十四 ) 、檢討排氣系統洩漏旁通問題 ( 十五 ) 、空調箱再熱 ( 十六 ) 、外氣引進控制 ( 十七 ) 、空調負荷確定 ( 十八 ) 、人員、設備操作維護之管理

- 4. 負荷計算

- 5. 一 . Clean Room Area : 11,182 m 2 ( 8,717 m 2 MAIN FAB) 二 . Re. Humidity : Photo : 43±3% , Production : 43±5% 三 . Temperature : Photo : 22±0.3 ℃ , Production : 22±2 ℃ 四 . Room Pressurization : Class1 : 5±1mmAq , Class1000 : 3±1mmAq System Specification Clean Room

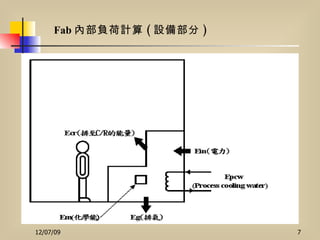

- 7. Fab 內部負荷計算 ( 設備部分 )

- 8. Fab 內部負荷計算

- 9. Q e = Q acid + Q alkaline + Q sol + Q general = 5,590 + 509 + 1,076 + 8,302 = 15,477 (CMM) Q m = Q photo + Q prod + Q imp + Q supp + Q gowning = 3,518 + 6,000 + 3,218 + 2,915 + 816 = 16,467 (CMM) Exhaust 風量 Fresh 風量 Fab 內部負荷計算

- 10. 設備用電為 7367 k W = 6,335,620 kcal =2095.1 RT INPUT: INTERNAL LOAD: FFU LOAD =160W * 7,270 =1,163.2 kW =1,000,352 kcal =330.8 RT LIGHITING LOAD =317.1kW =272,706kcal/hr =90.1 RT Fab 內部負荷計算

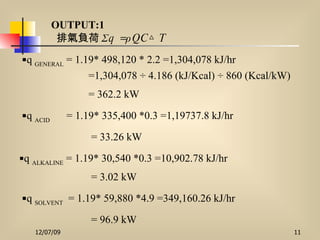

- 11. 排氣負荷 Σq =ρQC△T =1,304,078 ÷ 4.186 (kJ/Kcal) ÷ 860 (Kcal/kW) q GENERAL = 1.19* 498,120 * 2.2 =1,304,078 kJ/hr = 362.2 kW q ACID = 1.19* 335,400 *0.3 =1,19737.8 kJ/hr = 33.26 kW q ALKALINE = 1.19* 30,540 *0.3 =10,902.78 kJ/hr q SOLVENT = 1.19* 59,880 *4.9 =349,160.26 kJ/hr = 96.9 kW = 3.02 kW OUTPUT:1

- 12. PCW (q) =18,700 LPM OUTPUT:2 冷卻容量為 18,700 LPM *3.2*60 = 3,590,400 Kcal/hr =1,187.3 RT EXHAUST 帶走的熱量 = 140.77 RT 設備對 FAB 提供負荷 = 2,095.1 – 1,187.3 –140.77 = 767.03 RT Δ T = 3.2℃, IN=21. ℃ , OUT = 17.8 ℃

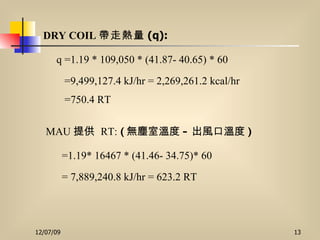

- 13. DRY COIL 帶走熱量 (q): q =1.19 * 109,050 * (41.87- 40.65) * 60 =9,499,127.4 k J/hr = 2,269,261.2 kcal/hr =750.4 RT MAU 提供 RT: ( 無塵室溫度 - 出風口溫度 ) =1.19* 16467 * (41.46- 34.75)* 60 = 7,889,240.8 k J/hr = 623.2 RT

- 14. 無塵室總負荷為 1,373.6 RT(MAU + DRY COIL) =1,373.6 – 767.03( 設備 ) – 90.1( 照明 ) – 330.8(FFU) 無塵室人員 , 滲透負荷及其他負荷 = 185.67RT 無塵室負荷

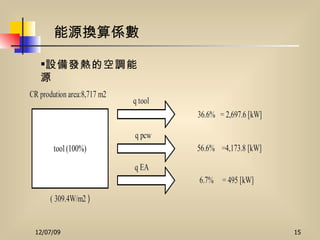

- 15. 設備發熱的空調能源 能源換算係數

- 16. 冷卻塔,冷水 / 冷卻水 pump 0.064 KWH / kW 合計 0.257 KWH / kW 每冷卻負荷 (kW) 所須要的電力能源 (KWH) 冷凍機 0.193 KWH / kW 冷卻負荷的電力能源

- 17. 內部負荷計算表 ◎ ( circulating Air System ) Dry coil 24 unit Dry coil (average load) 2,094 kWh/Day Dry coil (average volume) 41,167 m 3 /hr FFU 7,270 Unit FFU (average load) 27,916 kWh/Day FFU (average volume) 900 m 3 /hr FFU (static pressure ) 153 Pa

- 18. 內部負荷計算表 Energy Consumption Of Cleaning (FFU) -- Circulating Times (Times / hr) -- (1) Moving Energy (kW) 926.93 (2) Cooling Energy (kW) 1,163.17 (3) Total Consumption (kW) (1) + (2) 2,090.09 (4) (6) / Internal Loads 0.77 fan efficiency η =0.3

- 19. 內部負荷計算表 Energy Consumption Of FFU Type For Class 1 and 1000 CLASS 1 (0.1 um) CLASS 1000 (0.1 um) FFU input (W) 160 160 FFU quantity (SETS) 3117 4153 Floor area (M 2 ) 2341 8841 Energy Consumption (kW/M 2 ) 0.213 0.075

- 20. 排氣處理的能源 TYPE VOLUME (CMH) ENERGY CONSUMPTION (KWH/DAY) SYSTEN STATIC PRESSURE (Pa) kWH/m 3 CMM/m 2 ACID 335,400 6,885 -980 0.0009 0.500 GENERAL 498,120 8,599 -1,009 0.0007 0.742 ALKALINE 30,540 1,843 -882 0.0025 0.046 SOLVENT 59,918 3,087 -300 0.0021 0.089

- 21. 製程冷卻水的製造及運送能源 Energy consumption of PCW (flow) Chiller (1) Cooling Loads (kW) 4,173.00 (2) Pump Energy (kW) 447.21 (3) Total Cooling Loads (kW) (1) + (2) 4,620.21 (4) Cooling Energy (kW) 1,071.39 (5) Energy Consumption of Pump (kW) 447.21 (6) (4) + (5) 1,518.6 (7) Energy of Per unit (6)/ Volume (kW/m 3 ) 1.35 (8) Energy of Per Cooling Loads (6)/(1) (kW/kW) 0.36 (9) PCW Consumption of Per Square (LPM /M 2 ) 1.67

- 22. Per Square Area Energy Consumption of FAB 1 Average power consumption (kW) 16,793.4 2 FAB total area (M 2 ) 11,182.0 3 Production area of FAB (M 2 ) 8,717.0 4 (1) /(3) (kW/ M 2 ) 1.5 5 (1) /(4) (kW/ M 2 ) 1.9

- 23. Energy consumption benchmark Item REMARK Device cooling (kW /kW) 0.7750 FFU Fresh air (kW / m 3 ) 0.0042 INCLUDING FAN POWER EXHAUST (kW / m 3 ) 0.0007 GENERAL 0.0021 SOLVENT 0.0010 ACID 0.0021 ALKALINE Nitrogen (kW / m 3 ) 0.2209 Compressor (kW / m 3 ) 0.2250 PCW (kW / m 3 ) 1.3535 CHILLER UPW (kW / m 3 ) 9.1502 CHILLER (kW/kW) 0.1927 COOLING TOWER + CHILLED PUMP +COOLIN WATER PUMP (kw/kw) 0.0640

- 24. 外氣處理節能設計

- 25. 外氣處理能源 Energy consumption of Fresh Air Energy consumption of Fresh Air(max) kW / m 3 Loads Energy per unit kWh/kW Average Loads Per year Total consumption of Fresh Air kWh/m 3 Cooling 0.0136 0.2567 1 0.00350 Heating 0.0032 0.0147 1 0.00005 Humidity 0.0024 0.0287 0.3 0.00002 Consumption of Per Square (CMM / m2) 1.4726 Total Average of year 0.0036

- 26. 外氣空調箱 MAU 最佳化設計 潔淨評估比較如下: ( 一 ) 、風機位置 : 鼓風式及抽風式 ( 二 ) 、冰水系統 : 單冰水及雙冰水 ( 三 ) 、加熱系統 : 電熱及熱回收系統 ( 四 ) 、出風溫度

- 27. 外氣處理能源 在計算外氣空調箱耗電時,必須以能量及質量的平衡來分析; 能量平衡及質量平衡如下方程式所示: Q OA +Q Fan +Q AW +Q HC +Q W +Q E =Q CC1 +Q CC2 +Q MA M OA +M AW +M W =M CC1 +M CC2 +M MA +M P

- 29. 外氣空調箱 (MAU) 系統元件最佳化的選擇 能量平衡及質量平衡如下方程式所示:同樣的外氣空調箱 100,000 CMH 出風風量,其風車進風風量可減少 49.18 %((145584-97587) / 97587 * 100 % = 49.18 %) ,這對風車馬力隨著風車風量成正比關係來講,所減少的風車馬達購買成本及外氣空調箱的外觀尺寸將相形變小。 外氣空調箱各組合系統日平均風量比較圖

- 30. MAU 風機位置 : 鼓風式及抽風式 空調箱風機採抽風發熱可不成為盤管負荷並為再熱熱源。 每年可節約電力達 750,000kWH (1,500,000 元 ) 。 每年節約達 17% 。 外氣空調箱風機位置能量比較圖

- 31. MAU 冰水系統 : 單冰水及雙冰水 外氣空調箱單 / 雙冰水溫度能量比較圖 冰水溫度提高 1℃ 主機效率可提高 6% 。 可減少的冰水主機購買成本。 每年可節約電力達 97,000kWH (194,000 元 ) 。 每年節約達 2.3% 。

- 32. MAU 加熱系統 : 電熱及熱回收系統 外氣空調箱加熱系統能量比較圖 採冰水主機冷凝溫度回收供加熱使用,不須燃料或電力。 可減少鍋爐購買成本。 每年可節約電力達 957,000kWH (1,914,000 元 ) 。 每年節約達 29% 。

- 33. 外氣空調箱 (MAU) 系統元件最佳化的選擇 外氣空調箱各組合系統整年總耗電能比較圖 總耗電能隨著系統剛開始採用鼓風式單冰水電熱水鍋爐加熱系統慢慢改成最後的抽風式雙冰水冰機熱回收加熱系統而減少,其耗電量亦隨著外氣溫度的升高而提升。

- 34. 節能方面 降低外氣空調箱出風溫度的效益 已知無塵室的負荷為 : q infiltration + q clean room + q FFU + q Lighting + q people + q 其他 = q MAU + q Dry coil 調降出風口 1℃ 的效益 q MAU =ρQC△T = 1.19 * 16,467 * 60= 1,175,743.8 kJ/hr =1,175,743.8 ÷ 4.186 (kJ/kcal) ÷ 3024 (kcal/RT) = 92.8 RT 先前計算每冷卻負荷所須要之電力能源是 0.257 , 換算一日節省的電費為 : = 92.8( RT )*3,024(kcal/RT) ÷860(kcal/kW)*1.7( 平均購電成本 )*24 = $13,313.4 NTD

- 35. 外氣空調箱 (MAU) 出風溫度 外氣空調箱出風溫度變化能量比較圖 出風溫度降低 1℃ 一年可減少加熱量 300,000kW-hr(36.2%) 。 出風溫度降低 1℃ 一年可減少乾盤管能力 300,000kW-hr 。

- 36. PCW 節能設計

- 37. 製程冷卻水的節能 (1) Open system change to close system 冷卻容量為 18,700 LPM *3.2*60 = 3,590,400 KCAL/Hr 冷卻水溫度差△ T 為 3.2℃ ,揚程為 56M Open system 冷卻水量則為 (18,700 L/min) 。 =1187.3 RT 每日總耗電量為 10,733 KWH

- 38. 製程冷卻水的節能 (2) Close system 每日總耗電量為 6,816 KWH 冷卻容量為 14,640 LPM *4*60 = 3,590,400 Kcal/hr 冷卻水溫度差△ T 為 4℃ ,揚程為 34M 冷卻水量則為 (14,640 L/min) 。 =1161.9 RT

- 39. 製程冷卻水的節能 (3) (10,733 – 6,816) * 365 * 1.7 NTD/KWH (2002 年平圴購電成本 ) =NTD 2,430,498 Per year Open system change to close system 節省電費 : 節約電力折算二氧化碳減少量 : (10,733 – 6,816) * 365*0.65/1000=929.3 噸 / 年

- 40. Energy consumption of PCW(new) (flow) Chiller (1) Cooling Loads (kW) 4,174.8 (2) Pump Energy (kW) 284.00 (3) Total Cooling Loads (kW) (1) + (2) 4,458.8 (4) Cooling Energy (kW) 1,071.85 (5) Energy Consumption of Pump (kW) 284.00 (6) (4) + (5) 1,355.85 (7) Energy of Per unit (6)/ Volume (kW/m 3 ) 1.44 (8) Energy of Per Cooling Loads (6)/(1) (kW/kW) 0.32 (9) PCW Consumption of Per Square (LPM /M 2 ) 1.40

- 41. 排氣處理節能設計

- 42. Exhaust 靜壓調整 設備在安裝時往往將 EXHAUST 所需風量的安全係數加大, 為達到降低運轉成本,必須配合實際狀況逐步調整 造成安裝與實際運轉有很大的差距 EXHAUST 風量

- 43. Exhaust 靜壓調整 調整前 : 酸性排氣的管末端靜壓值為 86 mm A q 每日耗電量為 6,885KWH 鹼性排氣調整前的管末端靜壓值為 86.1 mm A q 每日耗電量為 1,843.2KWH 。 排風量為 5,590 CMM 排風量為 509 CMM

- 44. Exhaust 靜壓調整 調整後 : 酸性排氣的管末端靜壓值為 79 mm A q 每日耗電量為 6,833.5KWH 鹼性排氣調整前的管末端靜壓值為 79 mm A q 每日耗電量為 1,344.5KWH 。 排風量為 4 ,564 CMM 排風量為 450 CMM

- 45. 改善效益 : 降低排氣量 : ACID: (5,590-4,564)*60 = 61,560 CMH AKALINE: (509-450)*60 = 3,540 CMH 2,395,159.2 kW/ 年 *0.65/1000=1,334.4 噸 / 年 以 MAU 外氣平均耗能為 0.0042kW/m 3 計算 (61,560+3,540)*24*365*.0042=2,395,159.2 kW/ 年 折算二氧化碳減少量為 :

- 46. ENERGY OF EXHAUST (NEW) TYPE VOLUME (CMH) ENERGY CONSUMPTION (KWH/DAY) SYSTEN STATIC PRESSURE (Pa) KWH/ m 3 CMM / m 2 ACID 273,840 6,834 -744 0.0010 0.408 GENERAL 498,120 8,599 -1,009 0.0007 0.742 ALKALINE 27,000 1,334.50 -775 0.0021 0.040 SOLVENT 59,918 3,087 -300 0.0021 0.089

- 47. 降低 GENERAL EXHAUST(1) 酸,鹼性及有機溶劑等排氣系統,是考量設備與人員作業安全 一般排氣 (GENERAL EXHAUST) ,則是將設備的發熱源帶出 而增加的外氣空調箱的處理風量,則不符合能源的使用效率 由於外氣是經過冷卻除溼,加溼,加熱等的大量能源處理後 ,方可供生產使用,如果只因為將機台的發熱排出室外

- 48. 降低 GENERAL EXHAUST(2) GENERAL EXHAUST ,則可節省大量能源。 上述的資料可計算出外氣空調箱,平均處理 1CMH 的外氣 大約耗能為 0.0042 kW ,而 GENERAL EXHAUST 所帶出 的熱量每 CMH 為 0.00072kW ,由此可知適度降低 因降低 GENERAL EXHAUST 而對無塵室增加的負荷, 則可藉由降低 MAU 的出風溫度來補償。 預估可減少二氧化碳量為 : 498,120*(0.00 42 -0.00072)*24*365= 1,5185,088 kW/ 年 1,5185,088 kW/ 年 *.65/1000 = 9,870.3 噸 / 年

- 49. SOLVENT 熱能回收 : (1) VOC 系統分為 1. 排氣風車 2. 吸附槽內裝特殊沸石 (ZEOLITE) 之吸附槽 3. 燃燒爐 一 . 為直接將生產線所排出之有機溶劑氣體,經沸石吸附槽吸附後 排出乾淨空氣。 二 . 為將吸附槽中吸附飽合之高濃度有機物質 ( 濃縮 24 倍 ) ,利用 200 ℃ 高溫空氣脫附出高濃度有機物質,與瓦斯混合燃燒後 排放至大氣中,在燃燒溫度大於 650 ℃ 時即可去除 VOC

- 50. 仍需加熱到 725℃ 後,其中溫差達 686℃ ,造成大量的能源浪費 SOLVENT 熱能回收 : (2) 改善前狀況 : 將吸附槽中吸附飽合之高濃度有機物質,脫附後溫度為 39 ℃ 與瓦斯混合燃燒到 725 ℃ 後排放至大氣中,由於經熱交換器後 排放到大氣的溫度仍 高達 492℃ 而脫附後的氣體,與新鮮空氣熱交換後溫度降為 39℃ ,

- 51. 改善前狀況 : SOLVENT 熱能回收 : (3)

- 52. 的溫度由 39 ℃ 提升到 410 ℃ 。 改善後狀況 : SOLVENT 熱能回收 : (4) 避免上述的能源浪費,在脫附後與燃燒爐之間加裝一座 熱交換器,來提升脫附後的溫度,以達到節省能源的目的 改善後排氣溫度由 492 ℃ 降至 292 ℃ ,而進入燃燒爐前 熱量節能: Waste heat Q = Ma* CP*(T i -T o ) Q=67 m3/min*1.2kg/ m3*0.247Kcal/kg ℃ *60min/hr *(410 ℃ - 39 ℃ ) =442,056.8 kcal/hr

- 53. SOLVENT 熱能回收 : (5) 液態天然氣 (propane) 比重 :1.56 液態天然氣: 24,320 kcal/m 3 =15,589 kcal/kg 液態天然氣單價: 16.6 元 /kg 液態天然氣用量: 442,056.8 kcal/hr / 15,589 kcal/kg = 28.3 kg/hr 節省費用: 28.3kg/hr *24hr*16.6 元 /kg *30( 天 ) = 338,241.6 元 / 月 折算二氧化碳減少量為 : 442,056.8 kcal/hr*24*365/860=4502811.1KW/ 年 4502811.1KW/ 年 *0.65/1000=2926.8 噸 / 年

- 54. 改善後狀況 : SOLVENT 熱能回收 : (6)

- 55. 報告結束 敬請指教