6 s visual management

- 1. …Building Strategic Advantage through Enterprise Wide Improvement… ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only SBS 6S & Visual Management with Examples

- 2. 2 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only What is… 6-S and Visual Management learn what 6-S means learn what a visual work place is Learn what a visual device is Learn what visual management is learn how to establish 6-S (basic level) Objectives: … part of the Simpler Business System SM

- 3. 3 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only 5S – 6S Background 5-S… in Japanese factories focus: orderliness 6th S added in some US companies… Safety combines orderliness with safety / ergo overall intention: CLEAN, SAFE, ORDERLY

- 4. 4 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Establishing Cells establish cells first, then improve them LOWEST COST ONE BY ONE DEFECT- FREE ON DEMAND 1-Piece Flow Standard Work 6-S Pull Systems

- 5. 5 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Target State for Cells Establish Model Cells first Improve Cells After They are Established 1-ITEM FLOW STD. WORK Quality PULL SYS. SETUP REDUC- TION BASIC QUALITY CHECKS TPM TAKT TIME OUT -PUT LOT- SIZE 1 ZERO DEFECTS LEVEL- ING LOAD- LOAD DEFECT-FREE ON-DEMAND 1-BY-1 LOWEST COST 6S & VISUAL MANAGEMENT 1-ITEM FLOW STD. WORK Quality PULL SYS. DEFECT-FREE ON-DEMAND 1-BY-1 LOWEST COST 6S &VISUAL MANAGEMENT

- 6. 6 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only think of 6-S as a repeating action sequence: 1: SORT OUT - get rid of what’s not needed 2: STRAIGHTEN - organize what belongs 3: SCRUB - clean up, see and solve problems 4: SAFETY - make the work area safe 5: STANDARDIZE - assign tasks, track visually 6: SUSTAIN - keep it up (audit and insist) remember… this applies to all areas (value-adding and administrative) basic "6-S” is part of establishing any cell Overview

- 7. 7 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only 1: Sort Out GET RID OF WHAT’S NOT NEEDED start with a red tag campaign tag everything that looks disorderly or unsafe be ruthless (9/10 you'll be OK, you'll get over the 1/10) if in doubt throw it out if still in doubt, send it to a “red tag area” for resolution you should be removing truckloads of items… be tough (Sometimes you’ll need to ask for forgiveness later!)

- 8. 8 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Sort

- 9. 9 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only 2: Straighten ORGANIZE WHAT BELONGS create a place for everything deal with the open red tags from the "Sort Out" step: RESOLE UNSAFE CONDITIONS ORGANIZE PARTS OR MATERIALS RESOLVE THE THINGS YOU WERE AFRAID TO THROW OUT WRITE OFF OR SELL OFF OBSOLETE MATERIALS

- 10. 10 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only 6. Visual Management in Practice Best Practice Examples The Team’s Work cell – Target State 1. Identification of area 2. Identification of process, resources, and products 3. Identification of the team 4. Footprints on the floor 5. Footprints of tools and racks 6. Technical area 7. Communication and break areas 8. Information and instructions 9. Tool Board Visual Documentation 10. TWI - Std Work Documents Visual Production Control 11. Computer terminal 12. Production schedule 13. Maintenance schedule 14. Identification of RM and WIP Visual Quality Control 15. Monitoring signals for machines 16. Statistical process control (SPC) 17. Record of problems/defects Metrics/Key Measures 18. Goals, Objectives and Results- Product/Process Control Boards Visual Process 19. CI activities 20. Project List and mission statement 7 19 18 13 14 15 16 17 20 10 11 12 9 8 6 4 5 3 2 1 4 2 10

- 11. 11 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Straighten

- 12. 12 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only 3: Scrub CLEAN UP, SEE AND SOLVE PROBLEMS make the work area absolutely clean clean everything (equipment, floors, walls…) paint everything (equipment, floors, walls…) look for problems… LEAKS? LOOSE OR MISSING ITEMS UNSAFE CONDITIONS CAUSES OF MESSES OR PROBLEMS… QUALITY ISSUES solve problems (root cause), take corrective action (prevent)

- 13. 13 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Scrub Break Room - organized and clean

- 14. 14 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Cabinet under sink in Training Room Scrub

- 15. 15 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only 4: Safety MAKE THE WORKPLACE SAFER look for unsafe conditions look for potential for unsafe acts look for difficult tasks (are they ergonomic?) try the jobs yourself… where could you get hurt? list the opportunities resolve them put creativity before capital and put safety first!!!

- 16. 16 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Safety

- 17. 17 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Safety

- 18. 18 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Lock Out / Tag Out program includes a storage area at the entrance to the plant floor for all locks and tags (locks are color coded for operators, mechanics, and contractors). Also, there is a place at each machine to store locks and tags when not in use. Safety

- 19. 19 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only 5: Standardize ASSIGN TASKS AND MANAGE VISUALLY Who will do what to keep the area clean, safe and orderly? agree on daily and weekly tasks establish a visual management system for these tasks can you tell at a glance if the tasks have been done?

- 20. 20 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Standardize

- 21. 21 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only 6: Sustain KEEP IT UP (AUDIT AND INSIST) develop audit checklists for office and for shop floor assign the audit role to someone outside the area track the audit results (a bit of friendly competition?) hold yourselves accountable for sustaining

- 22. 22 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Sustain

- 23. 23 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Cell Tracking Center – Production Control Board

- 24. 24 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Insights areas with great 6-S usually also have great numbers basic 6-S is the first step in building a new culture if you expect 6-S, lead by example (your office!) be persistent (it's OK to nag)

- 25. 25 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Definition of a Visual Workplace A Clear and precise outcome A Visual Workplace is: A work environment that is self-ordering, self-explaining, self regulating, and self-improving Where what is supposed to happen does happen, on time, every time, day or night… Visual Management is managing a visual workplace

- 26. 26 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Definition of a Visual Device A Visual Devise is a mechanism or thing: intentionally designed To influence, direct, or limit behavior By making vital information available without speaking a word (Think of a supermarket; Where do you find the breakfast cereal?) Should transmit a non-verbal message in 5 Seconds Should tell us what we need to do (action) Should be at the point-of-use Translates data into information, information into meaning, and meaning into behavior

- 27. 27 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Visual Systems, Cells, or Communications Centers A Visual System is a cluster or group of visual devices, aimed at a single performance outcome Because these systems are self-explaining, we can be self- regulating Example: A standard car has on the average of 144 visual devices on or inside the car. Intentionally designed to help us drive, maintain, and repair the car A Visual Cell is a cluster of visual devices within a confined space A Communication Center is a cluster of visual information located near people collection areas or meeting locations

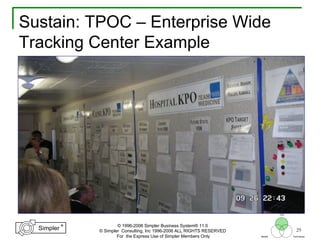

- 28. 28 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Sustain: TPOC – Enterprise Level Tracking Center

- 29. 29 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Sustain: TPOC – Enterprise Wide Tracking Center Example

- 30. 30 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Admin Cell Tracking Center

- 31. 31 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Sustain: Mission – Site Level Tracking Center

- 32. 32 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Sustain: Value Stream/Site Level Tracking Center (Mission)

- 33. 33 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Sustain: Value Stream – Mission Level Tracking Center/Board

- 34. 34 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Kaizen/Continuous Improvement Board – CI Events Tracking Center

- 35. 35 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Kaizen/Continuous Improvement Board – 6S Tracking Center

- 36. 36 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Sustain: Cell Tracking Centers - Kiosks

- 37. 37 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only 6S & Visual Management Examples Updated Hour-by-hour boards

- 38. 38 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Admin. (Design Center) Flow Cells with Cell Control Boards

- 39. 39 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Cell Tracking Centers – Production Control Board Examples

- 40. 40 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Key Points Sheet Example

- 41. 41 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Each machine has a posted start-up and shut-down procedure.

- 42. 42 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Cells – Small parts feeding systems Point of use Tools Boards

- 43. 43 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Low Volume, High Mix – Mix Model Cell

- 44. 44 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Single operator assembly cell example Clear plastic parts hoppers Point of use tools & controls Posted standard work doc’s

- 45. 45 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Work Cell Example Single Kit Assembly Boards Work Instructions Tool Boards at point of use Stand up cells Small parts at POU

- 46. 46 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only One Piece Flow Cell Example Posted Standard Work Job Instructions - JR

- 47. 47 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Team A3 Development Cell

- 48. 48 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Visual Controls – TPM Standard Work Example

- 49. 49 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Point of Use Tools – Work Cell

- 50. 50 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Tool Board Example (Tools at point of use) Tool Board

- 51. 51 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Assembly Cell Example

- 52. 52 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Assembly Cell Example with Automation

- 53. 53 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Cell Example

- 54. 54 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Color Coded Press with visual signals

- 55. 55 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Stamping Press - start of Set-up Reduction Event

- 56. 56 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Stamping Press - Information Board from TPM Event

- 57. 57 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Press - Decoiler, requires coil change with each die change

- 58. 58 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Press - Coil Feeder, front: Press - Coil Feeder, back (Feed adjustment required each change)

- 59. 59 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Stamping Press - Rear of press used to collect off-fall

- 60. 60 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Administrative CellAdministrative Cell –– One Piece Flow Example Design EngineeringOne Piece Flow Example Design Engineering Work FlowWork Flow Process Control Boards

- 61. 61 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Business Process Cell ExampleBusiness Process Cell Example

- 62. 62 ® Simpler ® Simpler Tool TechniquesBeliefs © 1996-2006 Simpler Business System® 11.0 © Simpler Consulting, Inc 1996-2006 ALL RIGHTS RESERVED For the Express Use of Simpler Members Only Administrative Flow Cell ExampleAdministrative Flow Cell Example Flow