Lean Six Sigma Implementation

- 1. Lean Six Sigma Implementation Copyright © 2005-2008 EMS Consulting Group Inc. All Rights Reserved

- 2. Agenda • Combining Lean and Six Sigma • The Laws of Lean Six Sigma • Deploying Lean Six Sigma Copyright © 2005-2008 EMS Consulting Group Inc. All Rights Reserved

- 3. Combining Lean and Six Sigma • The Lean Six Sigma Approach combines – The DMAIC Methodology (from Six Sigma) – Quality Tools (used in both Six Sigma and TPS) – Lean Tools (from TPS) Copyright © 2005-2008 EMS Consulting Group Inc. All Rights Reserved

- 4. Lean and Six Sigma Tools System Lean / Toyota Six Sigma Production System Philosophy •Elimination of •Reduction of waste defects/variation Improvement •PDCA •DMAIC Process/Cycle Tools VSM, 5S, Process Mapping, Standardized Work, SIPOC, Hypothesis Leveling, SMED, Testing, DOE, TPM, One Piece Control Charts, etc. Flow, Kanban, etc. Copyright © 2005-2008 EMS Consulting Group Inc. All Rights Reserved

- 5. The Laws of Lean Six Sigma Lean Six Sigma, George, 2002 • Lean means speed; it applies to all processes. • Slow processes are expensive processes. • The Lean metric is process cycle efficiency (Value-added Time/Total Lead Time) • Batch sizes must be calculated using flow variables • 95% of the lead times in most processes is wait time. • To improve speed, you need to identify and eliminate the biggest time traps using the Laws of Six Sigma Copyright © 2005-2008 EMS Consulting Group Inc. All Rights Reserved

- 6. The Laws of Lean Six Sigma Lean Six Sigma, George, 2002 • Laws of Six Sigma – The Law of the Market: Customer CTQ (critical-to- quality) issues must be addressed first. – The Law of Flexibility: Process Velocity is directly proportional to flexibility. – The Law of Focus: 80% of the delay in any process is caused by 20% of the activities – The Law of Velocity: The average velocity of flow through any process is inversely proportional to both the number of “things” in the process and the average variation in supply and demand. Copyright © 2005-2008 EMS Consulting Group Inc. All Rights Reserved

- 7. Execution of Lean Six Sigma 1. Initiation – Top Management becomes engaged in supporting the initiative. 2. Resource and Project Selection • Linked to Customer CTQ • Focus on creating value (high NPV projects) 3. Implementation / Sustainability / Evolution Copyright © 2005-2008 EMS Consulting Group Inc. All Rights Reserved

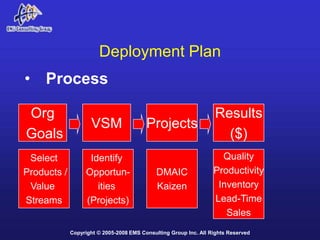

- 8. Deployment Plan • Process • Organization • Measures • Rewards • Tools Copyright © 2005-2008 EMS Consulting Group Inc. All Rights Reserved

- 9. Deployment Plan • Process Org Results VSM Projects Goals ($) Select Identify Quality Products / Opportun- DMAIC Productivity Value ities Kaizen Inventory Streams (Projects) Lead-Time Sales Copyright © 2005-2008 EMS Consulting Group Inc. All Rights Reserved

- 10. Deployment Plan • Organization Executive Leadership Resources Accountability Project Champions Resources Accountability Master Process Black Belt Black Belt Owners Team Members Copyright © 2005-2008 EMS Consulting Group Inc. All Rights Reserved

- 11. Deployment Plan: Organization MBB Black Belts Green Belts Yellow Belts Copyright © 2005-2008 EMS Consulting Group Inc. All Rights Reserved

- 12. Deployment Plan • Measures – Leading Indicators • # of champions identified • # of BB/GB identified and trained • Size and value of project queue – Financial Improvements linked to each initiative • Quality • Productivity • Inventory • Lead-Time • Sales Copyright © 2005-2008 EMS Consulting Group Inc. All Rights Reserved

- 13. Deployment Plan • Rewards – Bonuses tied to project performance (savings generated) for team leaders/participants. – Recognition – visible support from executives Copyright © 2005-2008 EMS Consulting Group Inc. All Rights Reserved